A fully automatic suspended reciprocating concrete ground grinding machine and its construction method

A construction method and concrete technology, which is applied in the direction of architecture and building structure, can solve the problems of different manual grinding strength, high quality requirements of the base layer, and long manual grinding time, so as to achieve simple mechanical installation and avoid pollution and harmful substances Harm to workers' health and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

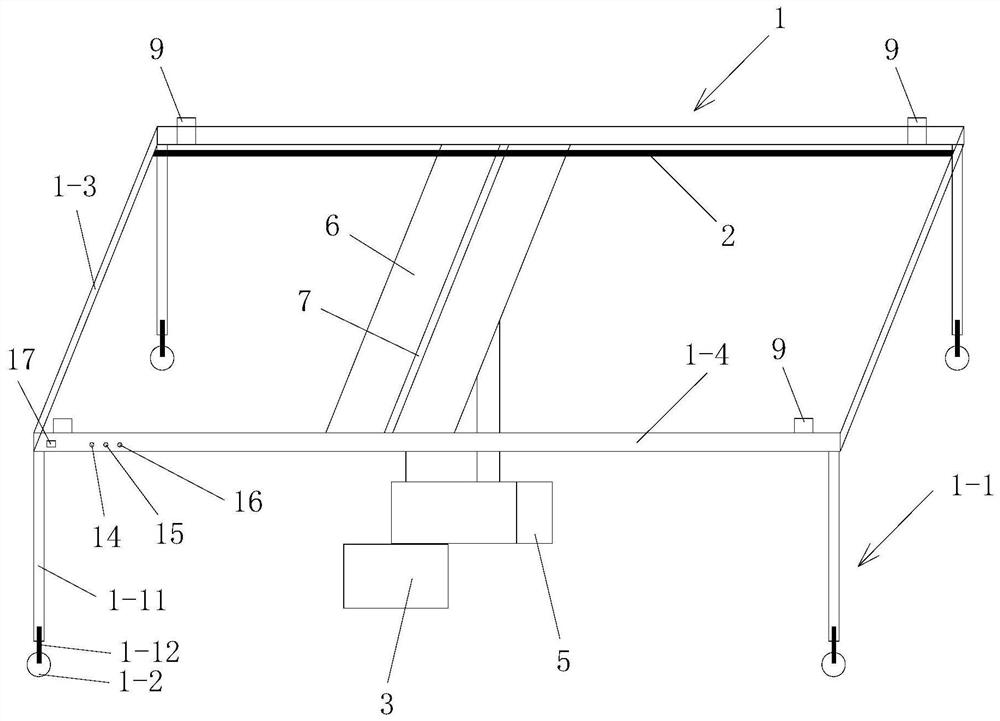

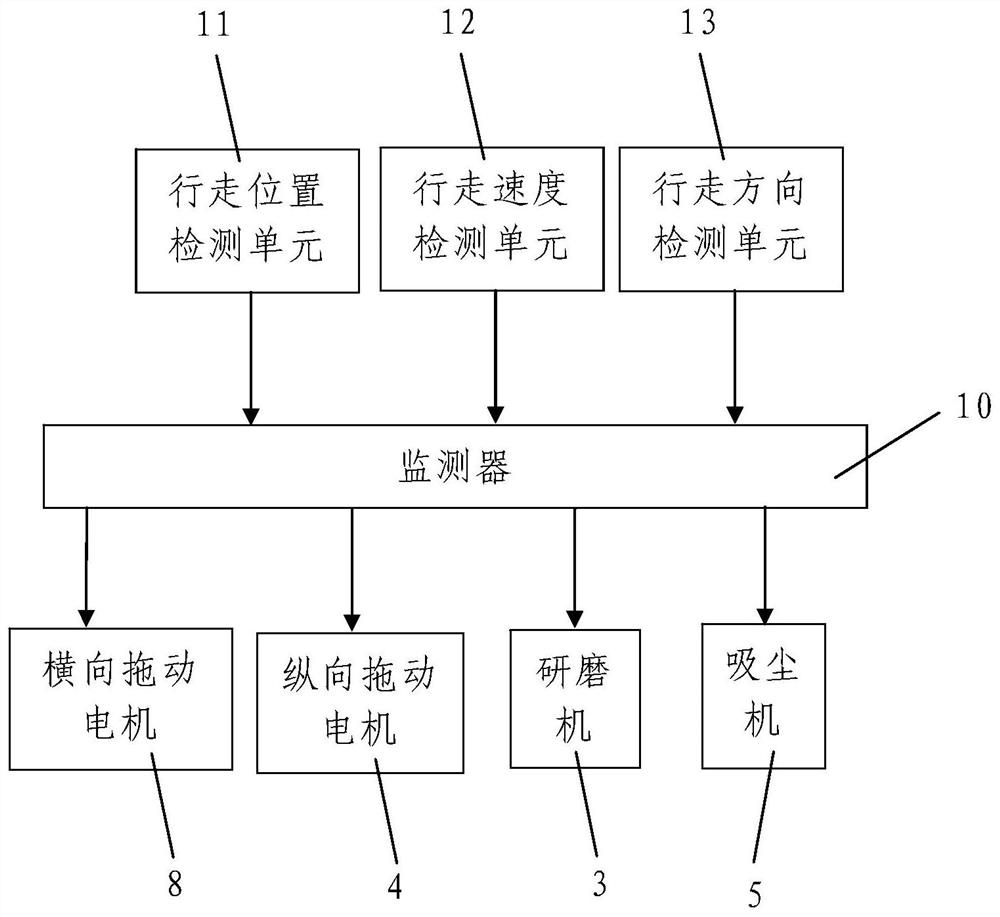

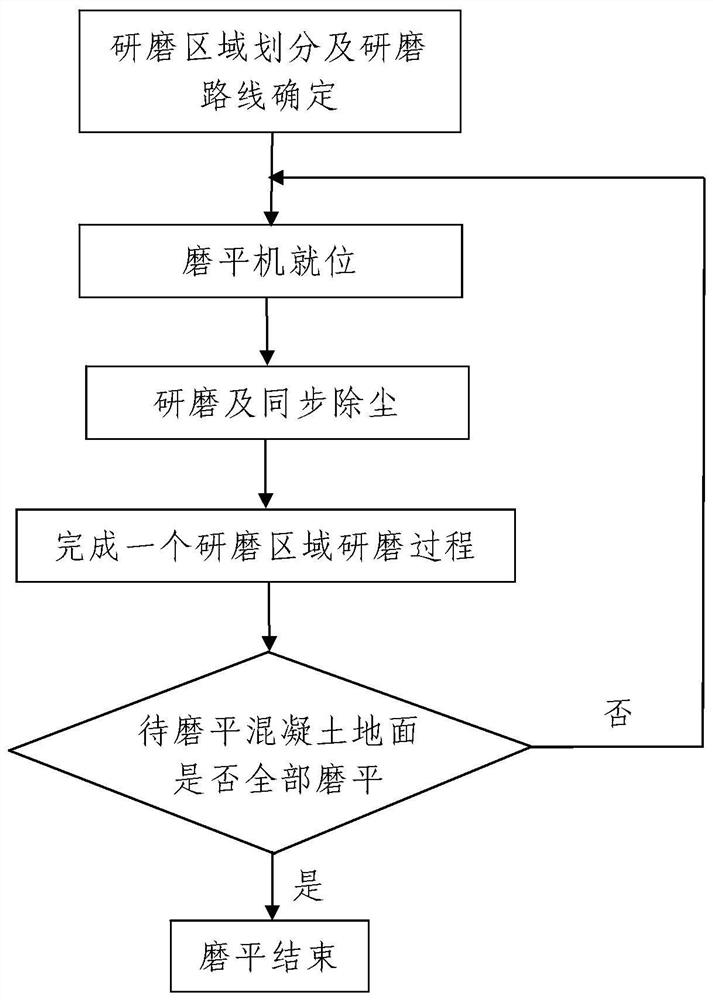

[0055] Such as figure 1 , figure 2 A fully automatic suspension reciprocating concrete ground smoothing machine shown includes a walkable frame 1 capable of moving back and forth on the concrete floor to be ground, a longitudinal guide rail 2 mounted on the walkable frame 1, and a longitudinal rail 2 mounted on the The translation frame 6 on the guide rail 2 and capable of moving back and forth along the longitudinal guide rail 2, the horizontal guide rail 7 which is installed on the translation frame 6 and can move synchronously with the translation frame 6, moves synchronously with the translation frame 6 and can move left and right along the horizontal guide rail 7 Grinder 3 that moves and grinds the concrete floor to be smoothed during the moving process, a vacuum cleaner 5 that moves synchronously with the grinder 3 and removes dust generated during the grinding process of the grinder 3, and drives the translation frame 6 along the longitudinal guide rail 2. A longitudi...

Embodiment 2

[0142] Such as Figure 4 , Figure 5 As shown, in this embodiment, the difference between the fully automatic suspension reciprocating concrete ground grinder used in Embodiment 1 is that the support frame is an arc frame;

[0143] The arc-shaped frame is spliced by two left and right arc-shaped longitudinal beams 1-5 arranged in parallel and two straight connecting beams 1-6 respectively connected between the front and rear ends of the two arc-shaped longitudinal beams 1-5 Formed, the two arc-shaped longitudinal beams 1-5 and the two described straight connecting beams 1-6 are all laid on the same plane; the circle centers of the two arc-shaped longitudinal beams 1-5 are the same and both The central angles are the same, and the two arc-shaped longitudinal beams 1-5 are respectively an outer arc-shaped beam and an inner arc-shaped beam located inside the outer arc-shaped beam, and the arc length of the outer arc-shaped beam is longer than that of the inner arc-shaped beam....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com