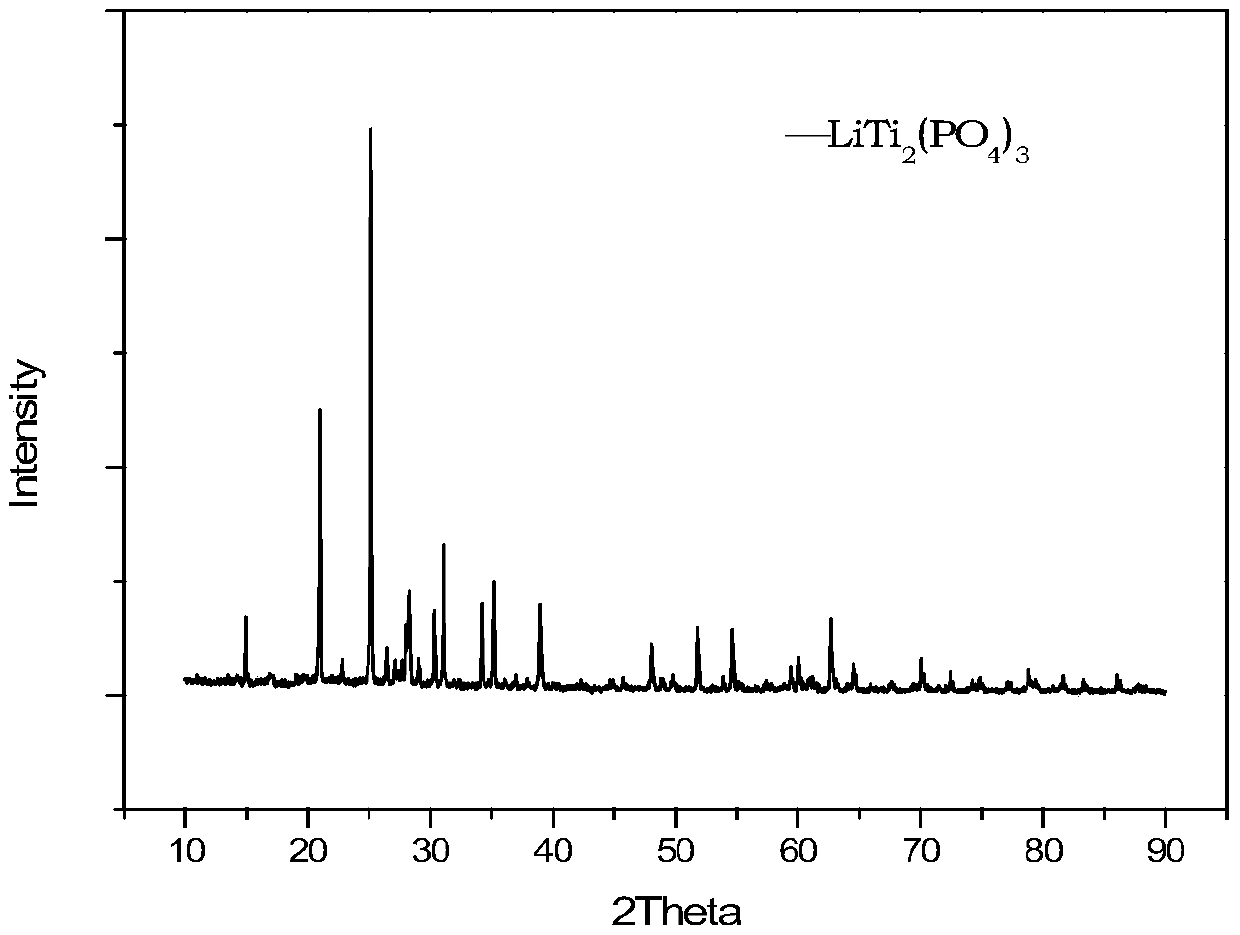

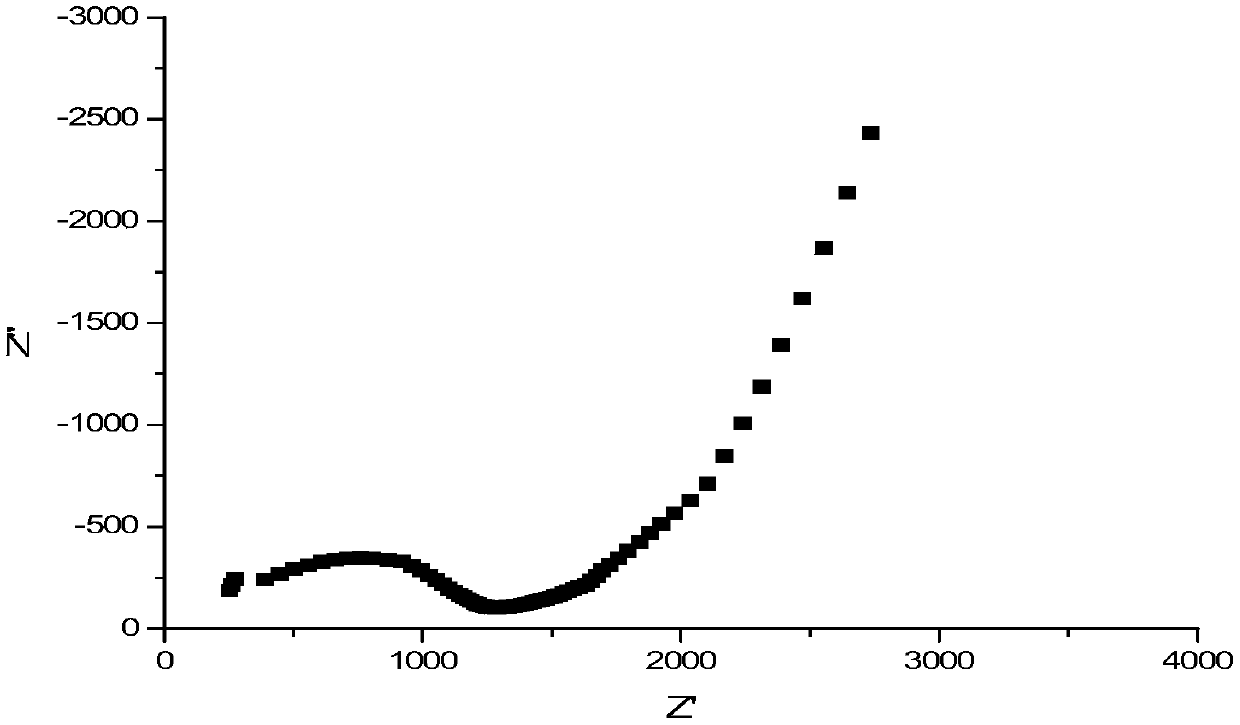

NASICON-type lithium ion solid electrolyte, preparation method and application thereof

A solid-state electrolyte, lithium-ion battery technology, applied in the field of lithium-ion batteries, can solve problems such as poor environmental stability, and achieve the effects of low manufacturing cost, energy reduction, and excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The preparation method of the NASICON type lithium ion solid state electrolyte of the present embodiment comprises the following steps:

[0021] (1) the raw material CH 3 COOLi, Al(NO 3 ) 3 9H 2 O, Ti(OC 4 h 9 ) 4 , NH 4 h 2 PO 4 Weigh according to the molar ratio of (1.3-1.5):0.3:1.7:3; add the raw materials into the reaction vessel in turn, and stir continuously at room temperature to form a light yellow slurry;

[0022] (2) Slowly add ammoniacal liquor to the reaction vessel, and simultaneously add a small amount of deionized water, then magnetically stir the reaction vessel in a water bath to form a uniform and stable layered white precipitate;

[0023] (3) Place the stable layered white precipitate in a blast drying oven, heat and dry to obtain a white precursor; pre-burn the precursor according to a temperature control program to obtain a white powder;

[0024] (4) The pre-calcined powder is dry-milled by a planetary ball mill, then pressed into tablets,...

Embodiment 2

[0033] The preparation method of the NASICON type lithium ion solid state electrolyte of the present embodiment comprises the following steps:

[0034] (1) the raw material CH 3 COOLi, Al(NO 3 ) 3 9H 2 O, Ti(OC 4 h 9 ) 4 , NH 4 h 2 PO 4 Weigh according to the molar ratio of (1.3-1.5):0.3:1.7:3; add the raw materials into the reaction vessel in turn, and stir continuously at room temperature to form a light yellow slurry;

[0035] (2) Slowly add ammoniacal liquor to the reaction vessel, and simultaneously add a small amount of deionized water, then magnetically stir the reaction vessel in a water bath to form a uniform and stable layered white precipitate;

[0036] (3) Place the stable layered white precipitate in a blast drying oven, heat and dry to obtain a white precursor; pre-burn the precursor according to a temperature control program to obtain a white powder;

[0037](4) The pre-calcined powder is dry-milled by a planetary ball mill, then pressed into tablets, ...

Embodiment 3

[0047] The preparation method of the NASICON type lithium ion solid state electrolyte of the present embodiment comprises the following steps:

[0048] (1) the raw material CH 3 COOLi, Al(NO 3 ) 3 9H 2 O, Ti(OC 4 h 9 ) 4 , NH 4 h 2 PO 4 Weigh according to the molar ratio of (1.3-1.5):0.3:1.7:3; add the raw materials into the reaction vessel in turn, and stir continuously at room temperature to form a light yellow slurry;

[0049] (2) Slowly add ammoniacal liquor to the reaction vessel, and simultaneously add a small amount of deionized water, then magnetically stir the reaction vessel in a water bath to form a uniform and stable layered white precipitate;

[0050] (3) Place the stable layered white precipitate in a blast drying oven, heat and dry to obtain a white precursor; pre-burn the precursor according to a temperature control program to obtain a white powder;

[0051] (4) The pre-calcined powder is dry-milled by a planetary ball mill, then pressed into tablets,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com