A flexible stretchable single-electrode triboelectric nanogenerator and a manufacturing method thereof

A technology of nanogenerators and flexible electrode layers, applied in the direction of triboelectric generators, etc., can solve the problems that nanofibers do not have stretchability, affect the output performance of triboelectric nanogenerators, limit the application value of flexible and wearable fields, etc., and achieve strong Adaptive shape, simple and light structure, and the effect of ensuring output stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

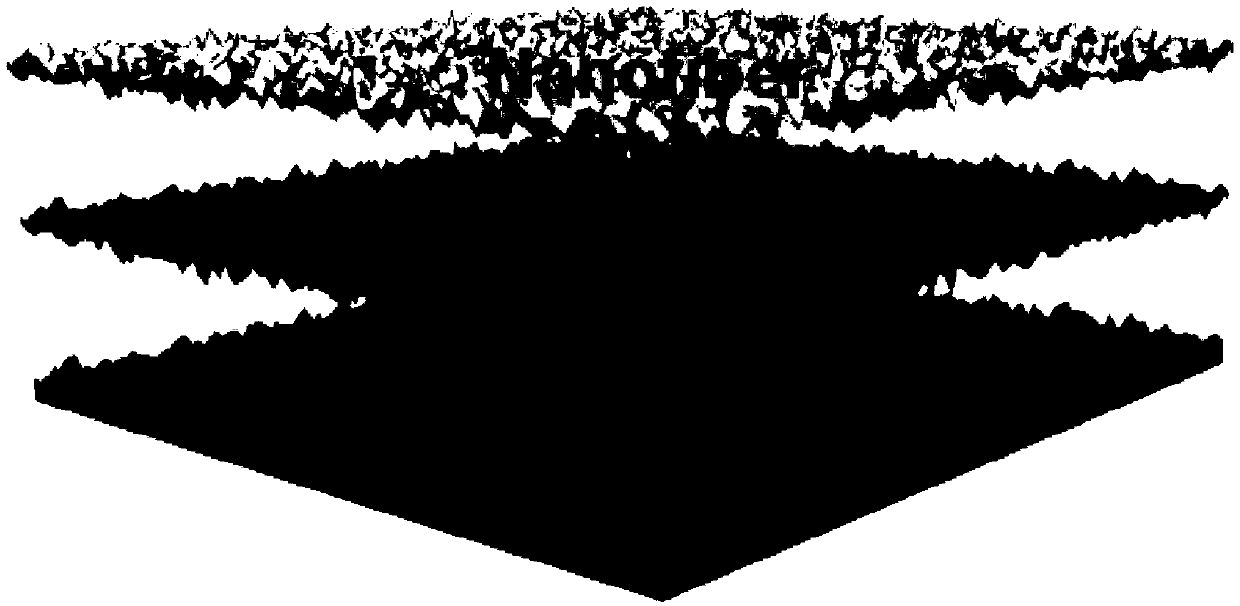

[0037] Step 1: Dilute the graphene oxide aqueous solution with an appropriate amount of deionized water, cast and drop it on a 200% pre-stretched 3M-VHB elastomer support film, and dry it in a blast oven to form a graphene oxide composite film.

[0038] Step 2: exposing the composite film obtained in step 1 to hydrogen iodide vapor, and reducing to obtain a conductive graphene composite film.

[0039] Step 3: Dissolve PVDF in an appropriate amount of DMF+acetone mixed solvent (6:4), stir magnetically for a period of time until it is completely dissolved, and obtain a polymer PVDF spinning solution.

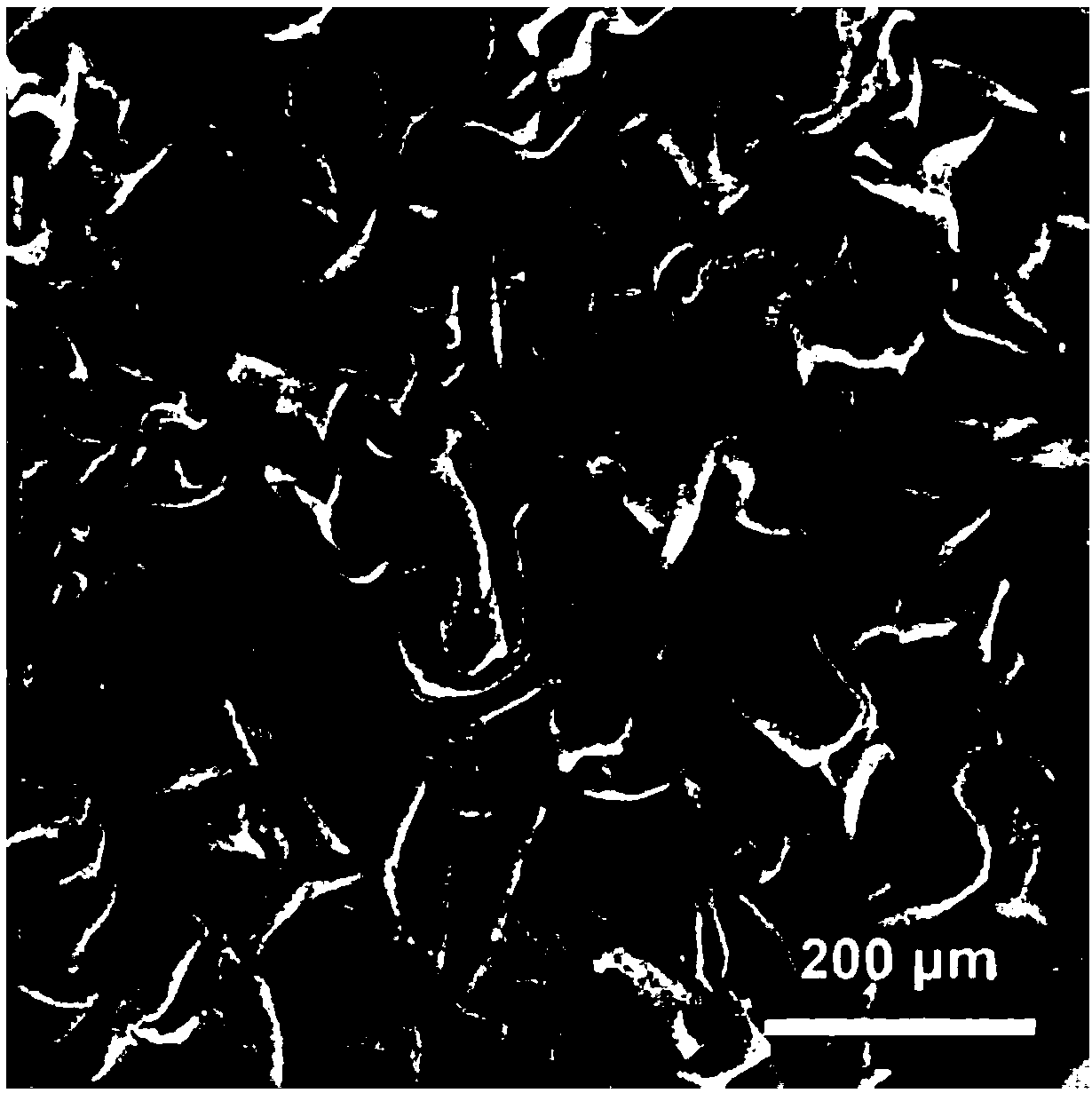

[0040] Step 4: Use the conductive graphene composite film as the receiving electrode, control the electrospinning operating parameters as voltage 10kV, receiving distance 20cm, temperature 30±5°C, humidity 30±5%, and propulsion speed 0.01mL / min etc. to obtain PVDF nanofibrous membranes.

[0041] Step 6: release the pre-stretching stress, put the composite membrane into a blast ov...

Embodiment 2

[0044] Step 1: Coating gold on the 200% pre-stretched 3M-VHB elastomer support film to obtain a conductive gold composite film.

[0045] Step 2: PET is dissolved in an appropriate amount of dichloromethane + trifluoroacetic acid mixed solvent (1:4), and magnetically stirred for a period of time until it is completely dissolved to obtain a polymer PET spinning solution.

[0046] Step 3: Use the conductive gold composite film as the receiving electrode, control the electrospinning operating parameters as voltage 12kV, receiving distance 18cm, temperature 30±5°C, humidity 30±5%, advance speed 0.01mL / min, etc. , to obtain PET nanofiber membrane.

[0047] Step 4: Release the pre-stretching stress, put the composite film into a blast oven at 160°C for heat treatment, and obtain a wrinkled triboelectric nanogenerator.

[0048] The results show that the output performance of the nanogenerator reaches 50V in the original state, and 160V under the condition of 150% tension (the pressin...

Embodiment 3

[0050]The flexible and stretchable single-electrode triboelectric nanogenerators of Examples 1 and 2 can not only be used to collect mechanical energy, but can also be attached to the skin surface at different positions of the human body. The movement of the human body, the triboelectric nanogenerator performs friction and stretches deformation at the same time, which can be used to monitor the information of human movement in real time, such as the amplitude of the movement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com