Anisotropic high-performance thermal interface material and preparation method thereof

A thermal interface material, anisotropic technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problems of easy leakage, difficult to improve thermal conductivity, corrosion of devices, etc., to improve thermal conductivity and effective heat. The effect of improved conductivity and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

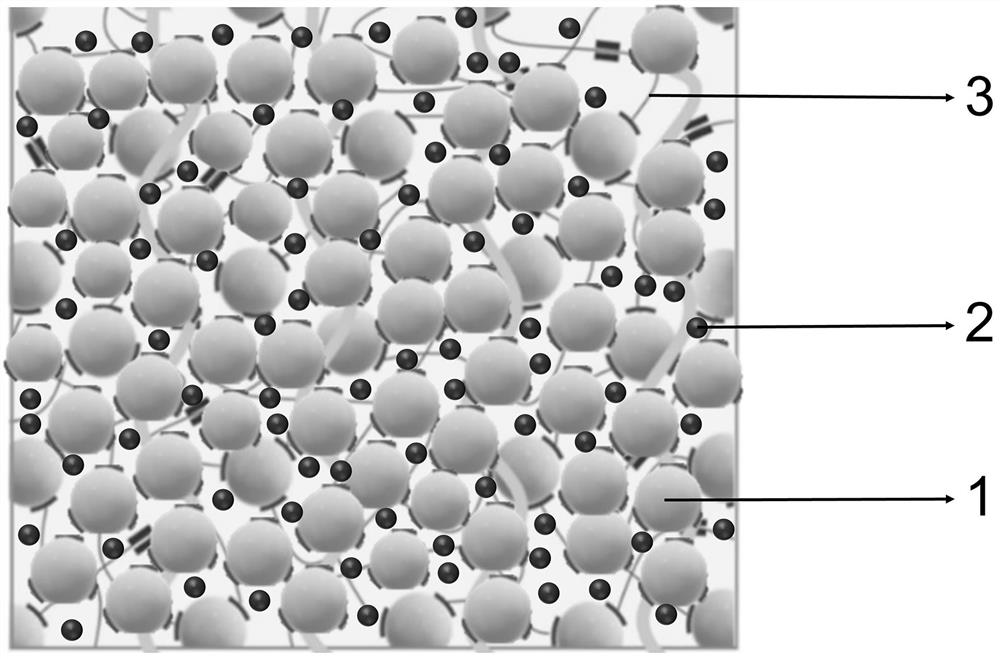

[0033] like figure 1 As shown, the high-performance thermal interface material with anisotropy provided in this embodiment includes a magnetic liquid metal 1 , magnetic particles 2 and a network skeleton 3 . Among them, the mesh skeleton 3 is made of flexible materials to separate the droplets of the magnetic liquid metal 1, and the magnetic liquid metal 1 is made of GaIn 21.4 It is composed of iron tetroxide particles, the flexible material is copolyester (Ecoflex), and the magnetic particles 2 are iron particles with a particle size of 1 micron.

[0034] In this embodiment, GaIn 21.4 That is, the mass of the eutectic gallium indium alloy is 500 grams, about 80 milliliters, the mass of iron tetroxide particles is 100 grams, the particle size is 1 micron, the Ecoflex system is 30 milliliters, and the volume of iron particles is 30 cubic centimeters.

[0035] The specific preparation process is as follows:

[0036] First, mix the liquid metal and the ferric oxide particles t...

Embodiment 2

[0043] Embodiment 2 is basically the same as Embodiment 1. For the sake of brevity, in the description of this embodiment, the same technical features as Embodiment 1 will not be described, and only the differences between this embodiment and Embodiment 1 will be described:

[0044] The thermal interface material with anisotropy provided in this embodiment 2, wherein the magnetic liquid metal passes through the Ga 68 In 21 Sn 11 It is mixed with ferric oxide particles, and the flexible material is polydimethylsiloxane (PDMS); the magnetic particles 2 are iron particles with a particle size of 2 microns.

[0045] In this embodiment, Ga 68 In 21 Sn 11 The mass of FeO is 500 g, about 80 ml, the mass of ferric oxide particles is 100 g, and the particle size is 3 microns; the system of polydimethylsiloxane (PDMS) is 30 ml, and the volume of iron particles is 30 cubic centimeters.

[0046] The specific preparation process is as follows:

[0047] First, mix the liquid metal and...

Embodiment 3

[0051] The high-performance thermal interface material with anisotropy provided in Example 3, the magnetic liquid metal passes through GaIn 10 It is mixed with NdFeB particles, the polymer is a hydrogel, and the magnetic particles 2 are iron particles with a particle size of 0.5 microns.

[0052] In this Example 3, GaIn 10 The mass of NdFeB particles is 500 g, about 80 ml, the mass of NdFeB particles is 100 g, the particle size is 0.5 microns, the system of hydrogel is 30 ml, and the volume of iron particles is 30 cubic centimeters.

[0053] The specific preparation process is as follows:

[0054] First, the liquid metal and NdFeB particles are mixed together, and stirred at a frequency of 290 rpm for 11 minutes by a mechanical stirrer. It can be seen that the surface NdFeB particles completely enter the liquid metal to obtain a magnetic liquid metal;

[0055] Then, put the magnetic liquid metal and iron particles obtained in the previous step into the hydrogel solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com