Microbolometer and preparation method thereof

A technology of microbolometer and nanowire array, which is applied in the field of microbolometer and its preparation, can solve the problems of large thermal conductivity of devices, poor chemical stability, and inability to obtain detection performance, so as to reduce heat conduction and improve detection with the effect of reading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

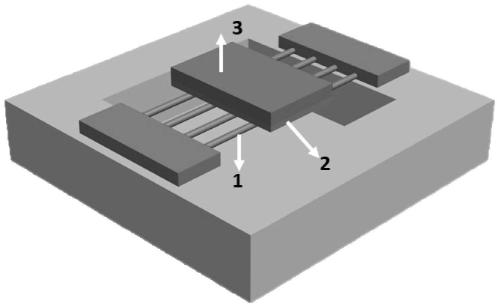

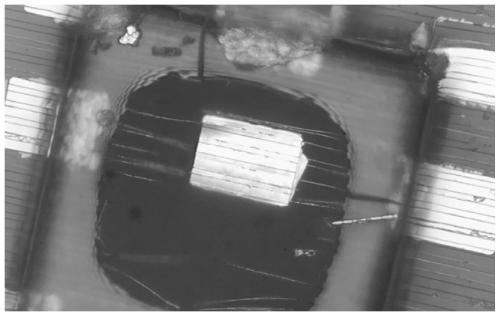

[0032] Such as Figure 2-3 As shown, this embodiment discloses a microbolometer, which includes a horizontally distributed planar semiconductor crystalline nanowire array 1 and amorphous silicon layered sequentially above the planar semiconductor crystalline nanowire array from bottom to top. Layer 2 and Silicon Nitride Layer 3.

[0033] Both ends of the planar semiconductor crystalline nanowires are provided with metal electrodes. Its metal electrodes can be PT (12nm)-AL (80nm) system, Ti-Au system, Ni and other metal materials, and the metal contact can be improved by rapid thermal annealing process. The evaporation method may use a thermal evaporation system, a magnetron sputtering system, or an electron beam evaporation system.

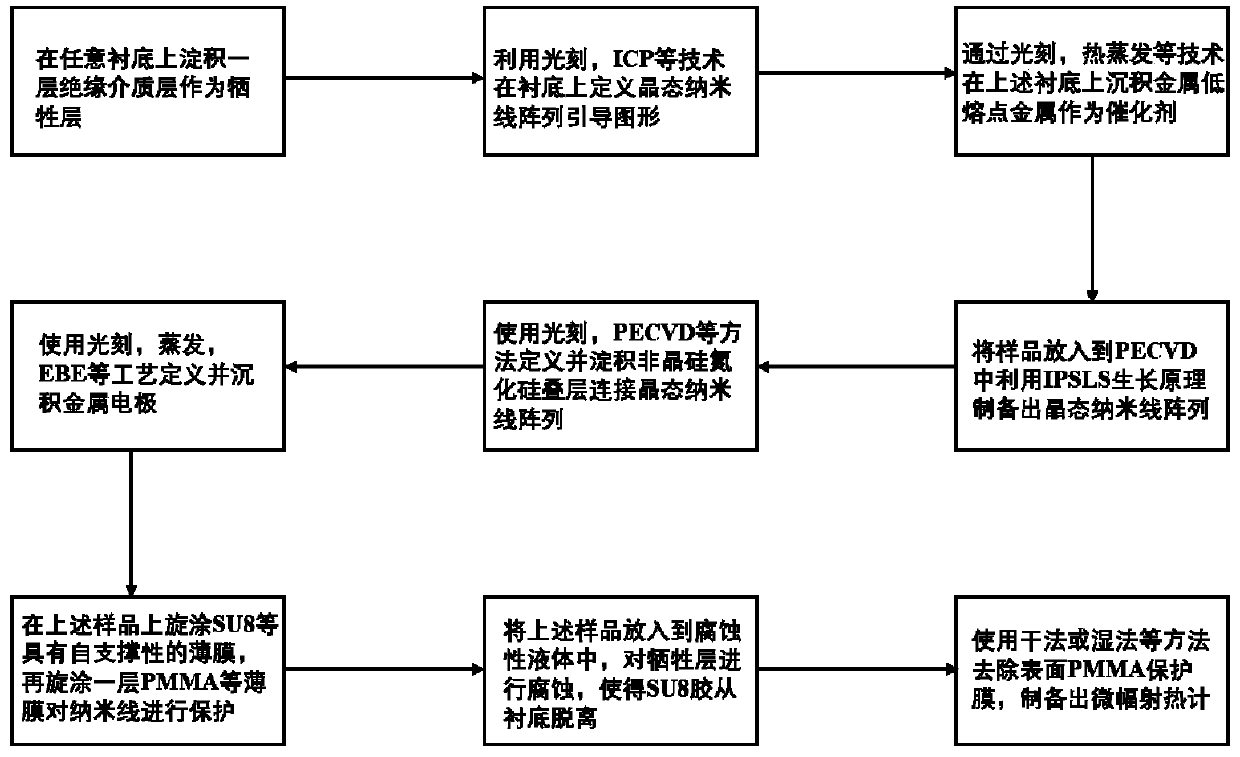

[0034] Also disclosed in this embodiment is a preparation method for a microbolometer, such as figure 1 As s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com