A photoresponsive and antifreeze elastic gel fiber and its preparation method

An elastic gel and fiber technology, applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc., can solve the problem of high energy consumption of gel fibers, complicated preparation process, and the inability of fibers to have both photoresponsiveness and frost resistance , elasticity and other issues, to achieve the effect of improving mechanical properties, simple preparation method, and adjustable modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

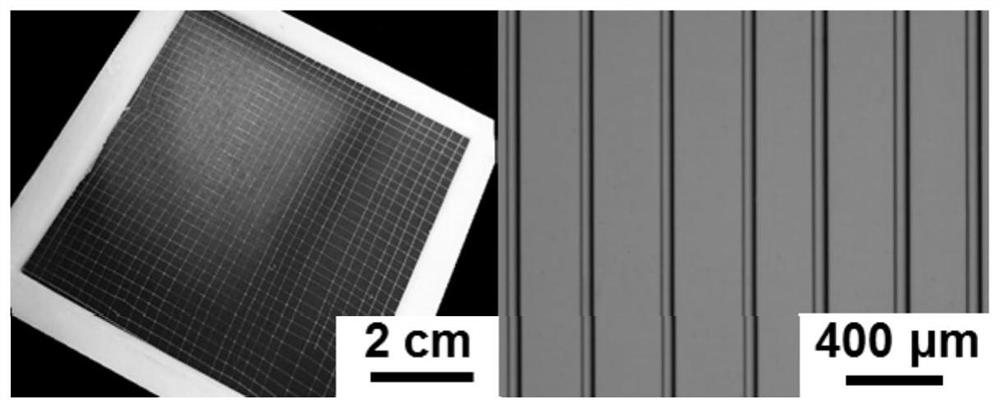

[0034] Prepare a mixed solvent of 2g glycerol (purchased from Sigma Company, the product number is V900122) and water, wherein the glycerin content is 20wt%, add 0.5g of ferrous chloride (purchased from McLean, the product number is 1811897) and 0.25 g of ferrous chloride to the solvent g of citric acid (purchased from Sigma Company, the product number is 791725), add 1 g of acrylamide-sodium acrylate copolymer (molar mass is about 450,000g / mol, wherein the acrylamide content is 75wt%) powder (purchased from Sigma company, product number 511471), stir evenly, take the above mixed solution with a syringe, let it stand, and perform microfluidic spinning after the bubbles are eliminated (ambient temperature: 25 °C; ambient humidity: 30%; Syringe pump extrusion speed: 10 μL / min; receiver rotation speed: 5 rpm) to obtain fibers, and the fibers can be further oxidized in the air to obtain light-responsive and frost-resistant elastic gel fibers. Using the horizontal uniform movement...

Embodiment 2

[0042] Configure a mixed solvent of 3g glycerol and water, wherein the glycerin content is 20wt%, add 0.45g of ferrous chloride and 0.25g of citric acid to the solvent, add 1.3g of acrylamide-sodium acrylate copolymer (mol The mass is about 450,000 g / mol, in which the acrylamide content is 80 wt%) and the powder is stirred evenly, and the mixed solution is taken with a syringe and left to stand. %; the extrusion speed of the syringe pump: 10 μL / min; the speed of the receiver: 5 rpm) to obtain the fiber, and the fiber can be further oxidized in the air to obtain the light-responsive and antifreeze elastic gel fiber. Using the horizontal uniform movement of the quadrilateral frame receiver, regular fiber arrays and fiber webs can also be obtained.

Embodiment 3

[0044] Configure a mixed solvent of 2g glycerol and water, wherein the glycerin content is 30wt%, add 0.5g of ferrous chloride and 0.35g of citric acid to the solvent, add 0.8g of acrylamide-sodium acrylate copolymer (mol The mass is about 450,000 g / mol, in which the acrylamide content is 85 wt%) and the powder is stirred evenly, and the mixed solution is taken with a syringe and left to stand. %; the extrusion speed of the syringe pump: 10 μL / min; the speed of the receiver: 5 rpm) to obtain the fiber, and the fiber can be further oxidized in the air to obtain the light-responsive and antifreeze elastic gel fiber. Using the horizontal uniform movement of the quadrilateral frame receiver, regular fiber arrays and fiber webs can also be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com