Steel slag framework-based ultrathin antiskid wearing layer and preparation method thereof

A steel slag and sliding grinding technology is applied in the field of road maintenance materials, which can solve the problems that the steel slag is not well applied, the transverse shear force of the road surface is large, and the road maintenance and repair effects are not particularly obvious, and achieves good anti-wear performance, Prevent road damage, high tensile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

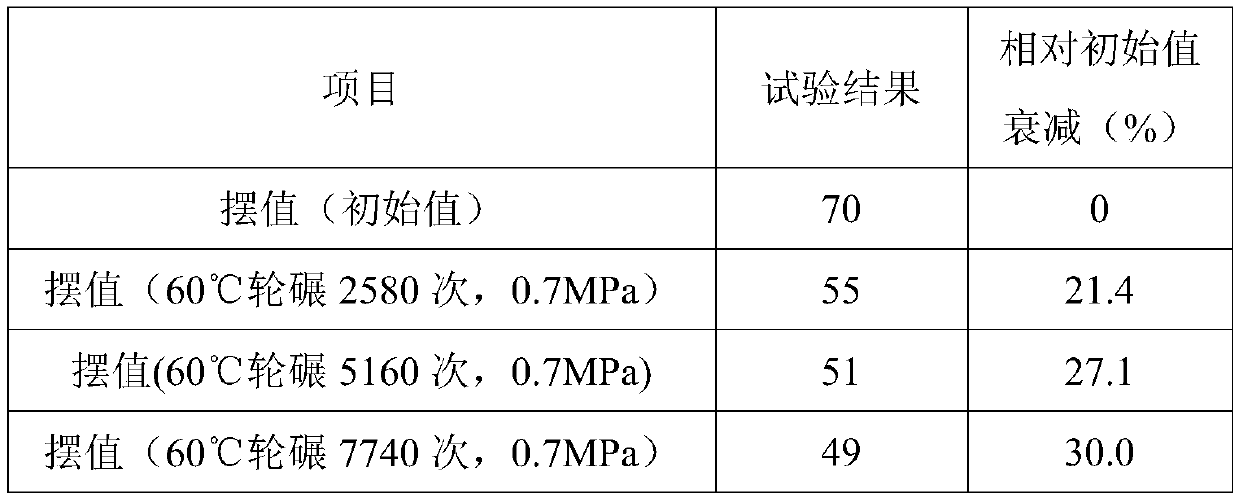

Embodiment 1

[0024] The steel slag aggregate after crushing and washing is used, the particle size distribution is 2.36-4.75mm, the stone chips are basalt, the particle size is less than 2.36mm, the sand equivalent is 70%, and the mass ratio of cement: mineral powder in the filler is 1:1 , the solid content of the modified emulsified asphalt is 62%, and the softening point of the evaporation residue is 55°C. The mass-to-number ratio of each material is steel slag aggregate: stone chips: filler: water: modified emulsified asphalt = 20:76:4:10:8.

[0025] The raw material of the modified emulsified asphalt includes the following components in parts by weight: 60 parts of base asphalt, 4 parts of waste rubber powder, 2 parts of N-dodecyl-1,3-propylenediamine, 1 part of additive , 38 parts of water.

[0026] The additive is obtained by mixing ammonium chloride and polyethylene glycol amine in a ratio of 1.5:1.

[0027] The modified emulsified asphalt is obtained from raw materials subjected ...

Embodiment 2

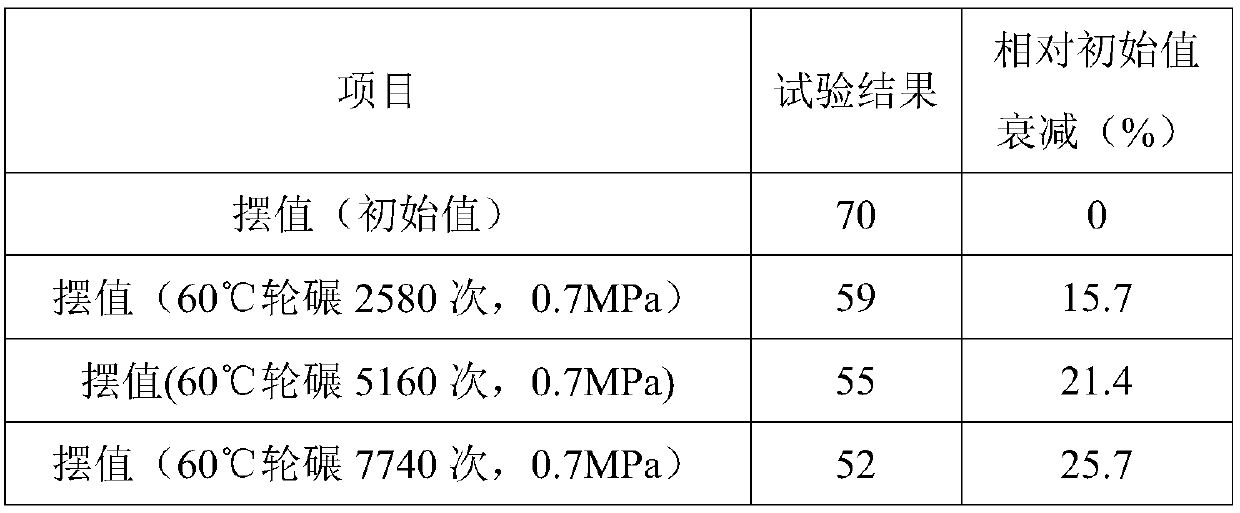

[0033] The crushed and washed steel slag aggregate is used, the particle size distribution is 2.36-4.75mm, the stone chips are diabase, the particle size is less than 2.36mm, the sand equivalent is 78%, and the mass ratio of the filler is cement: mineral powder = 1 :3, the solid content of the modified emulsified asphalt is 62%, and the softening point of the evaporation residue is 55°C. The mass ratio of each material is steel slag aggregate: stone chips: filler: water: modified emulsified asphalt = 26:70:5:6:12.

[0034] The raw material of the modified emulsified asphalt includes the following components in parts by weight: 60 parts of base asphalt, 4 parts of waste rubber powder, 2 parts of N-dodecyl-1,3-propylenediamine, 1 part of additive , 38 parts of water.

[0035] The additive is obtained by mixing ammonium chloride and polyethylene glycol amine in a ratio of 1.5:1.

[0036] The modified emulsified asphalt is obtained from raw materials subjected to high-speed shea...

Embodiment 3

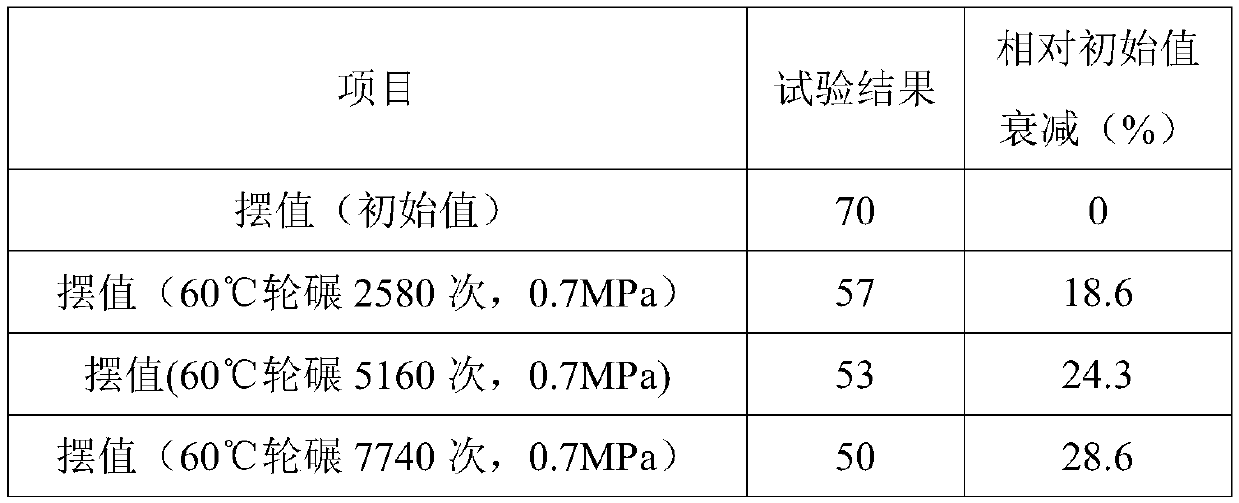

[0042] The crushed and washed steel slag aggregate is used, the particle size distribution is 2.36-4.75mm, the stone chips are basalt, the particle size is less than 2.36mm, the sand equivalent is 70%, and the mass ratio of cement: mineral powder in the filler is 1:2 , the solid content of the modified emulsified asphalt is 62%, and the softening point of the evaporation residue is 55°C. The mass ratio of each material is steel slag aggregate: stone chips: filler: water: modified emulsified asphalt = 23:75:2:8:10.

[0043] The raw material of the modified emulsified asphalt includes the following components in parts by weight: 60 parts of base asphalt, 4 parts of waste rubber powder, 2 parts of N-dodecyl-1,3-propylenediamine, 1 part of additive , 38 parts of water.

[0044] The additive is obtained by mixing ammonium chloride and polyethylene glycol amine in a ratio of 1.5:1.

[0045] The modified emulsified asphalt is obtained from raw materials subjected to high-speed shea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com