Novel graphene ternary composite direct current-carrying plate

A graphene composite and ternary composite technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve problems such as affecting the normal operation of equipment, short circuit of electrolytic cells, large current loss, etc., to promote the industrial production market, and reduce current loss. , the effect of good porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

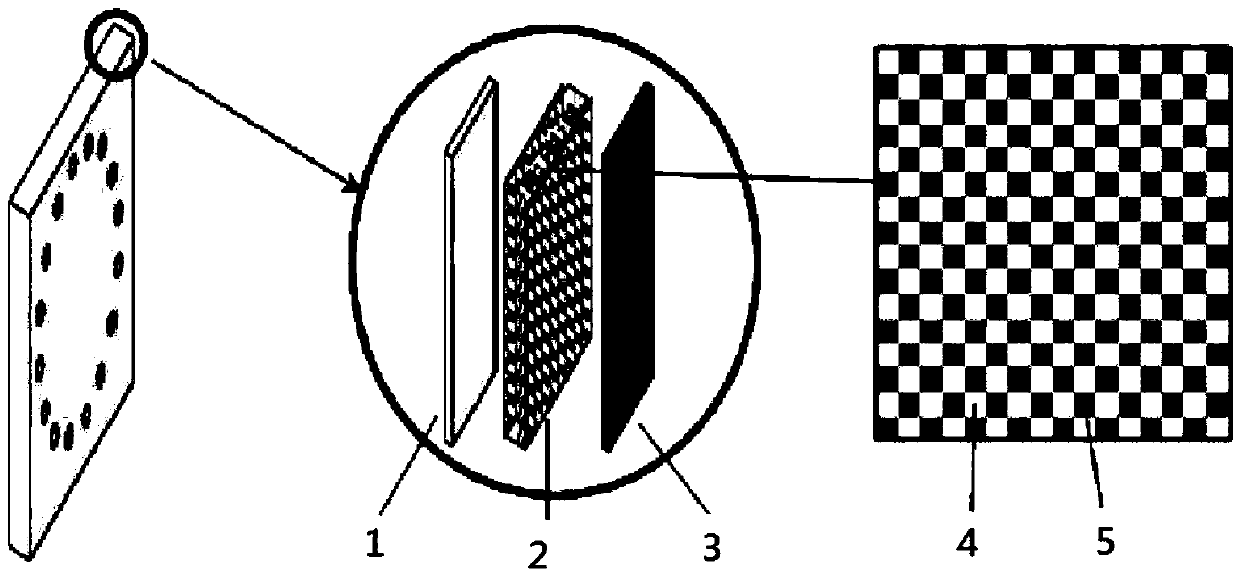

[0023] Such as figure 1 As shown, a novel graphene ternary composite direct current-carrying plate includes: a titanium plate; a graphene composite layer placed between the anode plate and the cathode plate; wherein, the graphene composite layer is doped in an aluminum mesh frame structure A certain proportion of graphene is added, which has high electron mobility, carrier transport efficiency and current density; and steel plate.

[0024] The anode plate is a titanium plate, and the cathode plate is a steel plate. The screen frame structure of the graphene composite layer is a circular hole reticular aluminum layer structure, a certain proportion of graphene mixed in the composite layer structure, and the mass percentage of graphene accounting for the composite layer is 5%;

[0025] The thickness of the direct current-carrying plate is 20mm, wherein: the thickness of the graphene composite layer is 3mm; the titanium plate is ternary coating of titanium substrate, and the thi...

Embodiment 2

[0027] Such as figure 1 As shown, a novel graphene ternary composite direct current-carrying plate includes: a titanium plate; a graphene composite layer placed between the anode plate and the cathode plate; wherein, the graphene composite layer is doped in an aluminum mesh frame structure A certain proportion of graphene is added, which has high electron mobility, carrier transport efficiency and current density; and steel plate.

[0028] The anode plate is a titanium plate, and the cathode plate is a steel plate. The filter screen frame structure of the graphene composite layer is a circular hole reticular aluminum layer structure, a certain proportion of graphene mixed in the composite layer structure, and the mass percentage of graphene accounting for the composite layer is 3%;

[0029] The thickness of the direct current-carrying plate is 16mm, wherein: the thickness of the graphene composite layer is 2mm; the titanium plate is ternary coating of titanium substrate, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com