Method for rapid heating, gasification and combustion of coal under high CO2 enrichment high-pressure environment

A rapid heating and high-pressure environment technology, applied in the thermal development of materials, the preparation of test samples, etc., can solve the problems of difficult access to laboratory equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

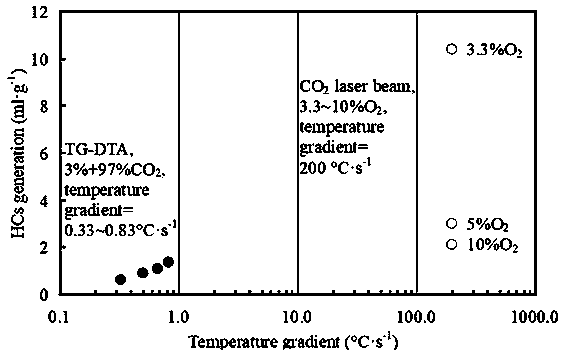

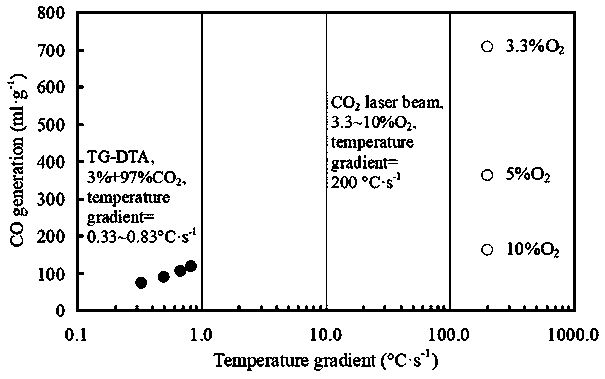

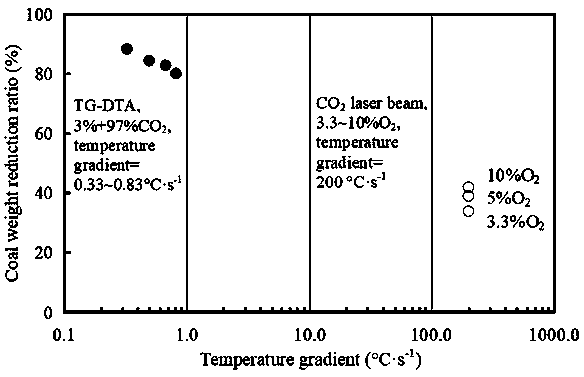

[0053] The present invention provides a method using CO 2 The experimental method of rapid heating and gasification combustion of coal under high pressure environment, the steps are as follows:

[0054] Ⅰ. Collection and preparation of coal samples

[0055]The collected coal samples come from the 8103 working face of Tashan Coal Mine in Shanxi. First, the collected coal samples are dried and crushed into coal particles with a diameter of 0.25-0.5 mm. Secondly, considering the influence of water content on the properties of coal samples, three different coal samples were specially selected. No. 1 coal sample is 20mg dry coal without moisture; No. 2 coal sample is 20mg coal-water mixture. It is prepared by mixing 20mg of dry coal with different water; No. 3 coal sample is prepared by immersing 20mg of dry coal particles in water placed in a vacuum chamber, and kept in a closed space with saturated water vapor for one Month, the total mass is also 20mg. Similar to the preparat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com