Application of piezoelectric material barium titanate in ultrasonic activation of persulfate for wastewater treatment

A piezoelectric material and persulfate technology, applied in the field of water treatment, to achieve the effect of increasing removal efficiency, accelerating degradation efficiency and rate, and promoting removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

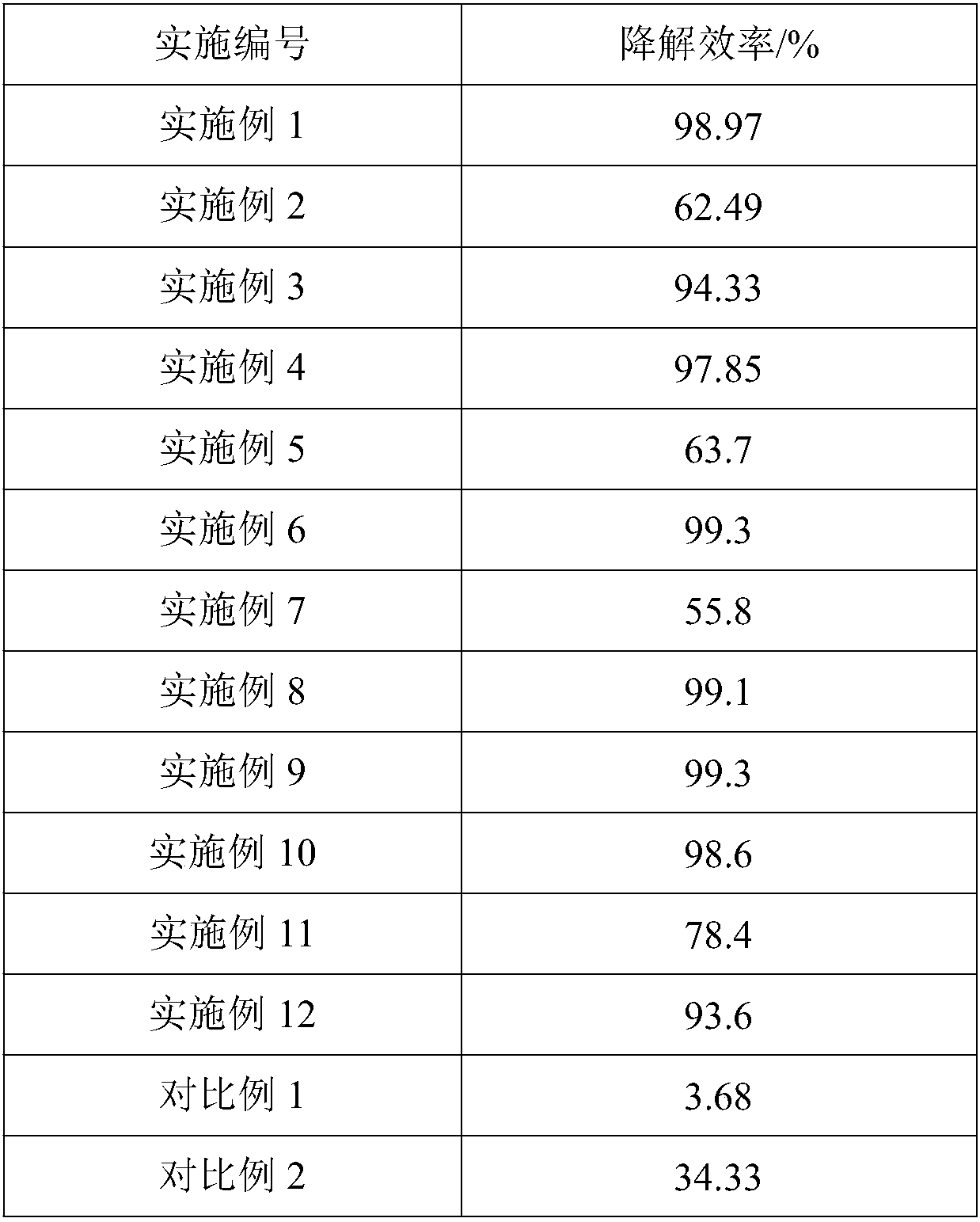

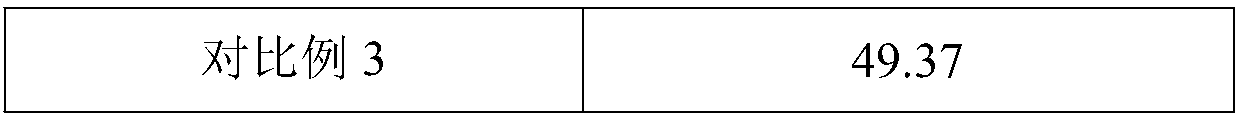

Embodiment 1

[0047] A method for ultrasonically activating persulfate with piezoelectric material barium titanate to treat wastewater, as follows: the piezoelectric material barium titanate powder is added to 25 mL of wastewater to be treated, the organic matter in the wastewater is ibuprofen, and the concentration is 6.0 mg / L , the dosage of piezoelectric material is 2.0g / L, the dosage of potassium persulfate is 1.00mmol / L, put it into a 110W, 40KHZ ultrasonic instrument for ultrasonic-piezoelectric degradation of pollutants for 60min. Samples were taken every 10 minutes to determine the efficiency of ultrasonic-piezoelectric material-persulfate to remove organic pollutants.

[0048] Wherein the preparation method of barium titanate is:

[0049] S1. Take 40 mL of tetraethyl titanate and slowly drop it into 400 mL of 1.0 mol / L acetic acid solution drop by drop. After magnetic stirring at room temperature for 72 hours, centrifuge at 10,000 rpm for 5 minutes. Discard the supernatant, wash t...

Embodiment 2

[0052] A method for ultrasonically activating persulfate with piezoelectric material barium titanate to treat wastewater, as follows: the piezoelectric material barium titanate powder is added to 25 mL of wastewater to be treated, the organic matter in the wastewater is ibuprofen, and the concentration is 6.0 mg / L , the dosage of piezoelectric material is 2.0g / L, the dosage of sodium persulfate is 0.5mmol / L, put it into a 110W, 40KHZ ultrasonic instrument for ultrasonic-piezoelectric degradation of pollutants for 60min. Samples were taken every 10 minutes to determine the efficiency of ultrasonic-piezoelectric material-persulfate to remove organic pollutants.

Embodiment 3

[0054] A method for ultrasonically activating persulfate with piezoelectric material barium titanate to treat wastewater, as follows: the piezoelectric material barium titanate powder is added to 25 mL of wastewater to be treated, the organic matter in the wastewater is ibuprofen, and the concentration is 6.0 mg / L , the dosage of piezoelectric material is 2.0g / L, the dosage of potassium persulfate is 0.75mmol / L, put it into a 110W, 40KHZ ultrasonic instrument for ultrasonic-piezoelectric degradation of pollutants for 60min. Samples were taken every 10 minutes to determine the efficiency of ultrasonic-piezoelectric material-persulfate to remove organic pollutants.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com