Treatment method for high-ammonia-nitrogen wastewater containing manganese and uranium

A technology for wastewater treatment and high ammonia nitrogen, which is applied in water/sewage treatment, heating water/sewage treatment, neutralized water/sewage treatment, etc. Guarantee the discharge standard and realize the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

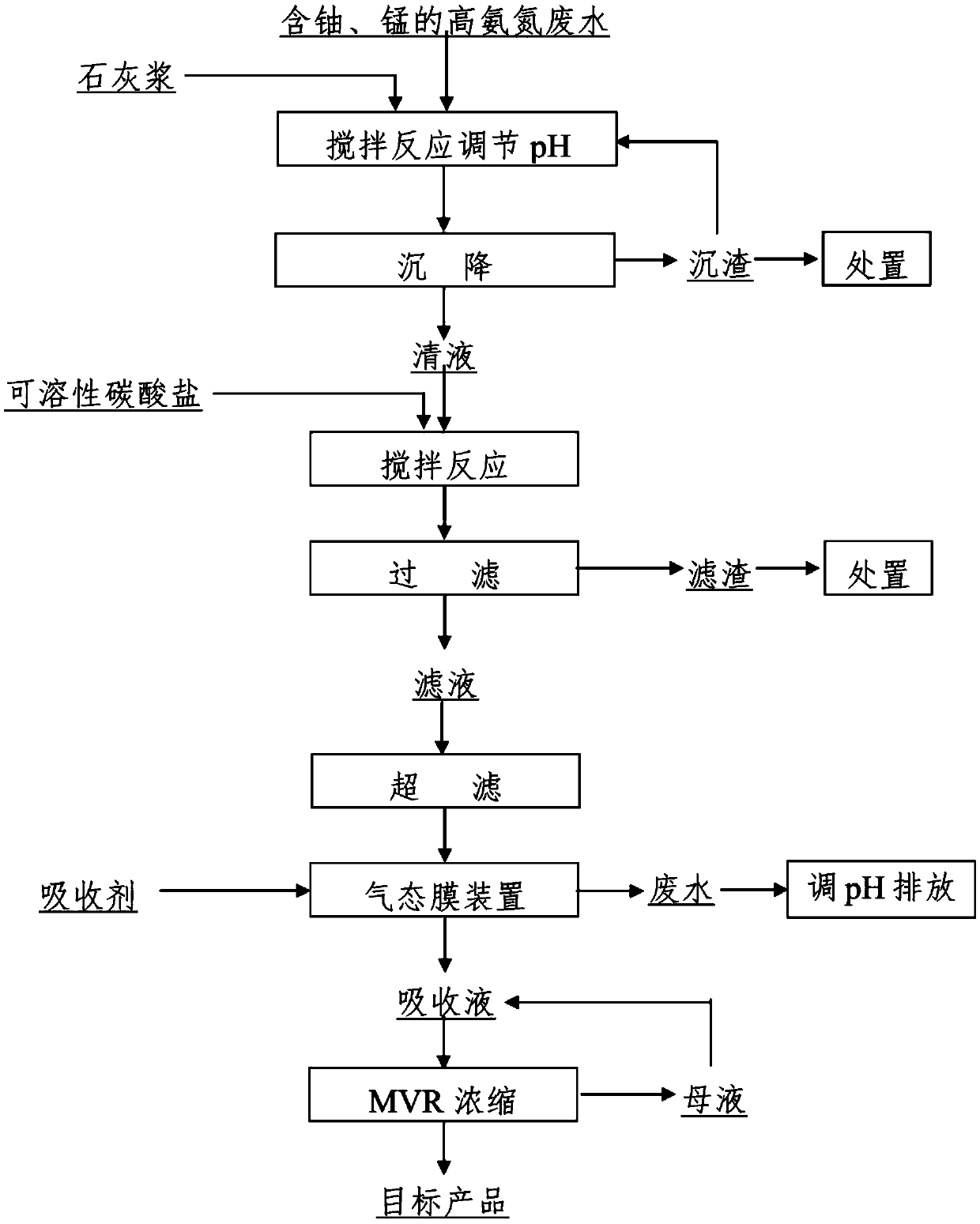

Method used

Image

Examples

specific Embodiment

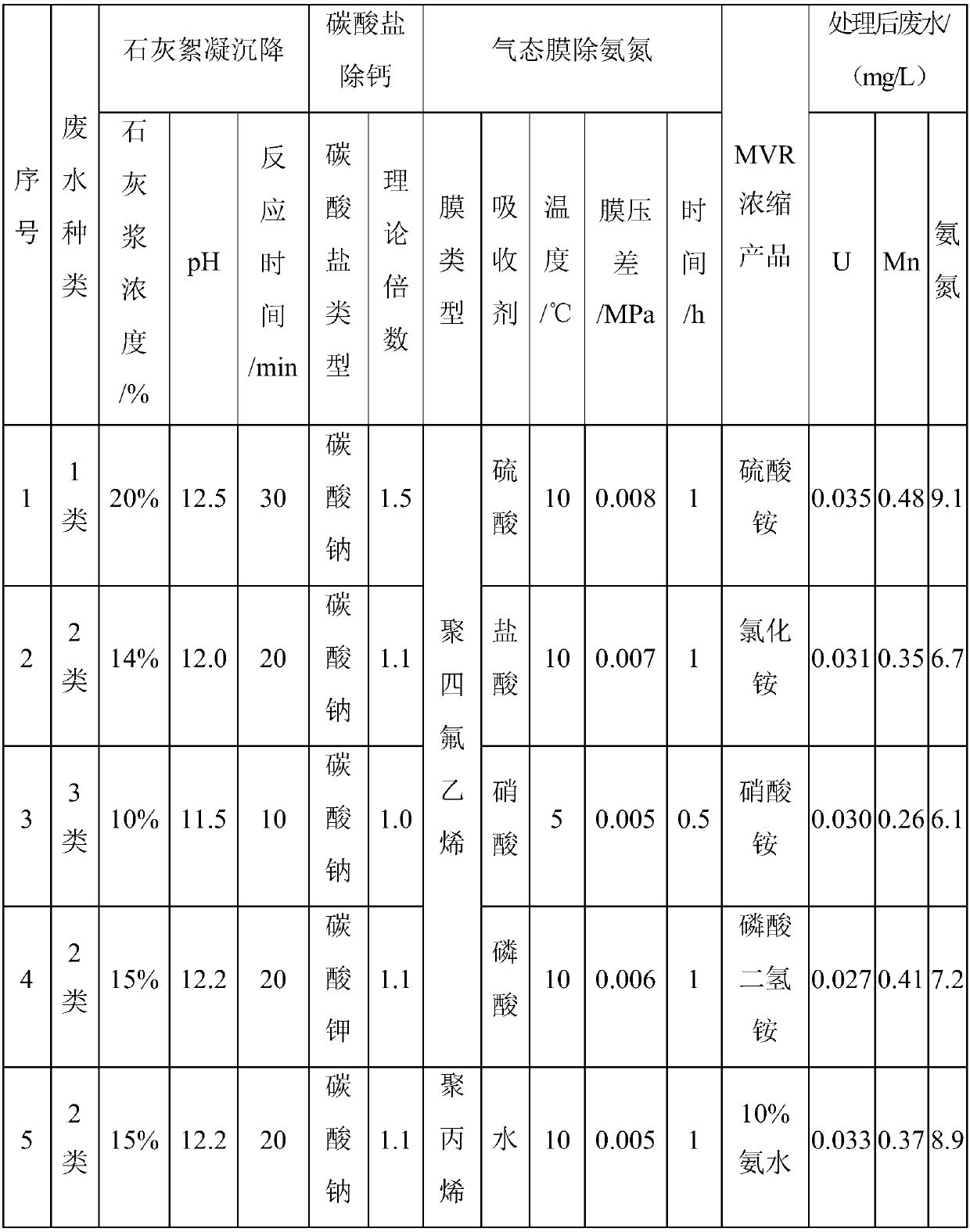

[0041]The present invention will be further described below in conjunction with the accompanying drawings and embodiments. During the implementation process, three types of wastewater with different components were treated and studied. The specific composition of wastewater is shown in Table 1. During the treatment process, the sediment obtained from the lime settlement of the waste water is returned to the cycle. After 4 cycles, starting from the 5th time, the corresponding quality of the sediment is discharged according to the mass of the newly generated sediment in each cycle; the stirring reaction time for carbonate decalcification is 10 minutes; Ammonia nitrogen gaseous membrane area 1.5m 2 , MVR concentration temperature 100-110 ℃, other process conditions and results are shown in Table 2.

[0042] Table 1 The main components of wastewater mg / L

[0043] components

Ammonia nitrogen

Na +

Mg 2+

Ca 2+

mn 2+

U

SO 4 2-

NO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com