Regeneration technology of industrial and mining waste oil

A waste oil regeneration, industrial and mining technology, applied in the petroleum industry, catalytic cracking, cracking and other directions, can solve the problems of oil odor and peculiar smell difficult to remove, high density, pollute the environment, etc., to achieve the effect of pure smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

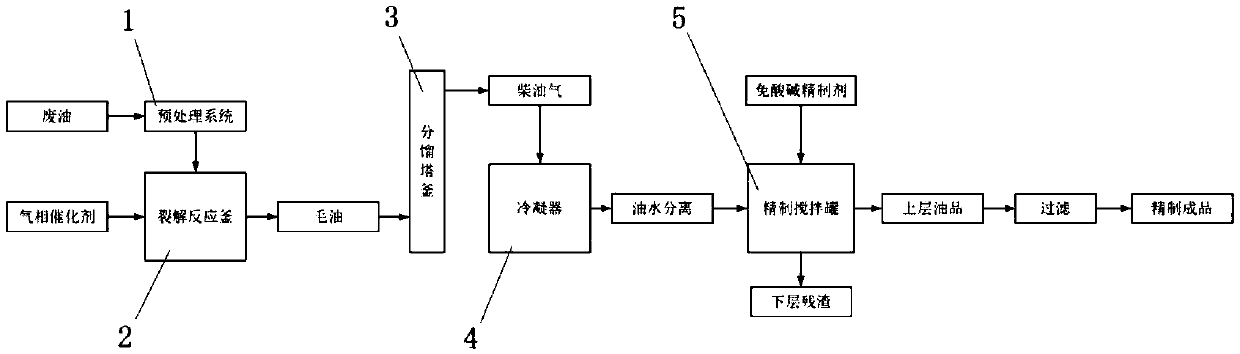

[0122] A process for recycling industrial and mining waste oil, comprising the following steps:

[0123] Step 1: Carry out pretreatments such as dehydration, removal of impurities, removal of sludge, removal of gums, removal of oxidation, etc. on the waste oil.

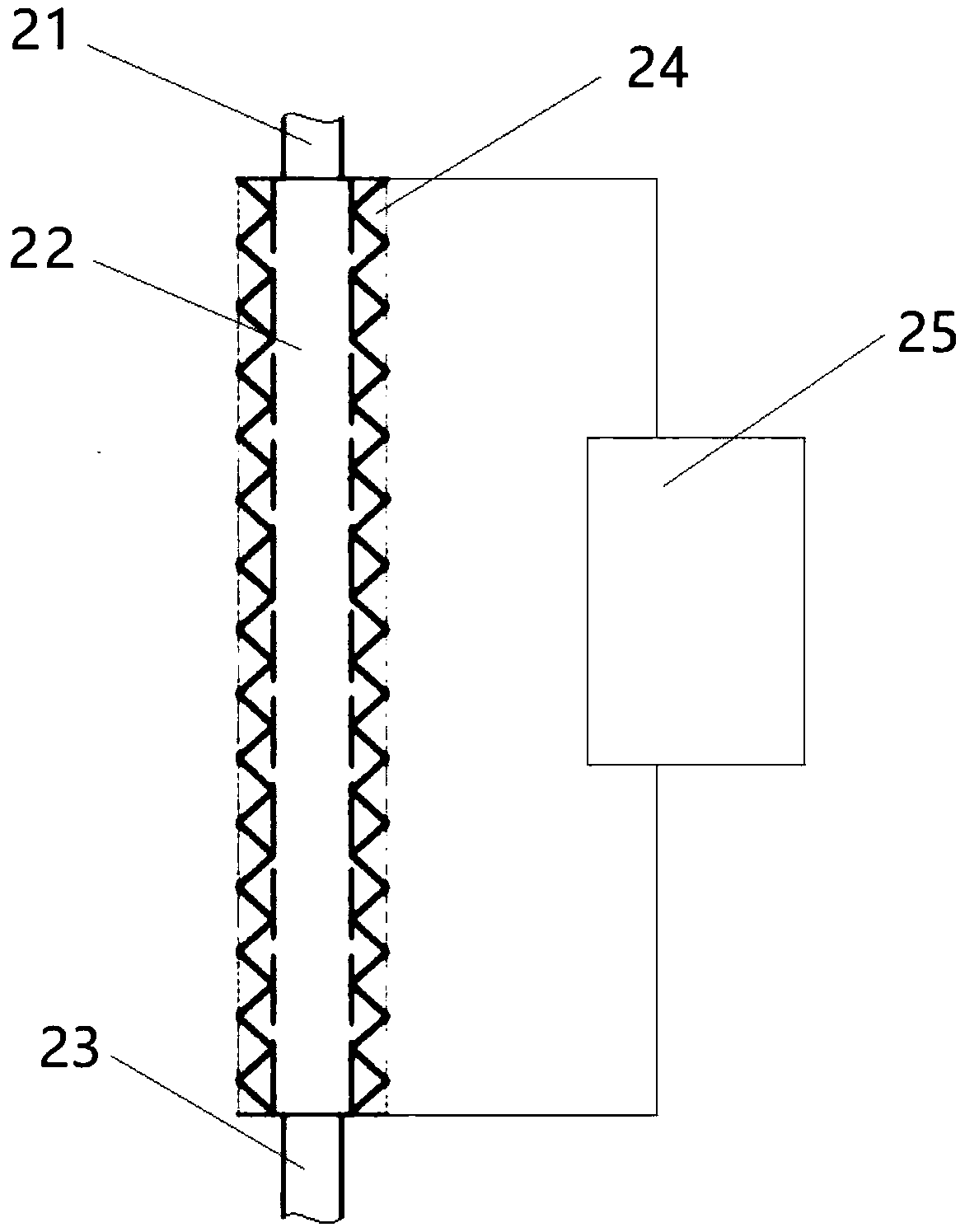

[0124] Step 2: pump the waste oil pretreated in step 1 into the head tank, control the flow rate of the pretreated waste oil and transport it to the cracking reactor, and raise the reaction temperature to 380-430°C within 20 minutes, Then a gas-phase catalyst is added into it, and under the action of the gas-phase catalyst, the pretreated waste oil is catalytically cracked to form crude oil close to the molecular structure of diesel oil.

[0125] Step 3: The cracked oil vapor coming out of the gas-phase catalytic tower in the step 2 enters into a fractionation tower kettle with a height of about 3.5 meters and a diameter of about 40 centimeters, and the diesel gas distilled by the packing in the tower is drawn out fro...

Embodiment 2

[0140] A process for recycling industrial and mining waste oil, comprising the following steps:

[0141] Step 1: Carry out pretreatments such as dehydration, removal of impurities, removal of sludge, removal of gums, removal of oxidation, etc. on the waste oil.

[0142] Step 2: Pump the waste oil pretreated in step 1 into the head tank, control the flow rate of the pretreated waste oil and transport it to the cracking reactor, and increase the reaction temperature to 420-470°C within 20 minutes, Then a gas-phase catalyst is added into it, and under the action of the gas-phase catalyst, the pretreated waste oil is catalytically cracked to form crude oil close to the molecular structure of diesel oil.

[0143] Step 3: The cracked oil vapor coming out of the gas-phase catalytic tower in the step 2 enters into a fractionation tower kettle with a height of about 3.5 meters and a diameter of about 40 centimeters, and the diesel gas distilled by the packing in the tower is drawn out ...

Embodiment 3

[0158] A process for recycling industrial and mining waste oil, comprising the following steps:

[0159] Step 1: Carry out pretreatments such as dehydration, removal of impurities, removal of sludge, removal of gums, removal of oxidation, etc. on the waste oil.

[0160] Step 2: Pump the waste oil pretreated in step 1 into the head tank, control the flow rate of the pretreated waste oil and transport it to the cracking reactor, and raise the reaction temperature to 350-400°C within 20 minutes, Then a gas-phase catalyst is added into it, and under the action of the gas-phase catalyst, the pretreated waste oil is catalytically cracked to form crude oil close to the molecular structure of diesel oil.

[0161] Step 3: The cracked oil vapor coming out of the gas-phase catalytic tower in the step 2 enters into a fractionation tower kettle with a height of about 3.5 meters and a diameter of about 40 centimeters, and the diesel gas distilled by the packing in the tower is drawn out fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com