Preparation process of low melting point composite material reinforced by carbon-based nanometer material

A technology of carbon-based nanomaterials and composite materials, applied in the field of preparation of carbon-based nanomaterials reinforced low-melting point composite materials, to achieve the effects of improving tensile strength, improving wettability, and rapid atomic diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

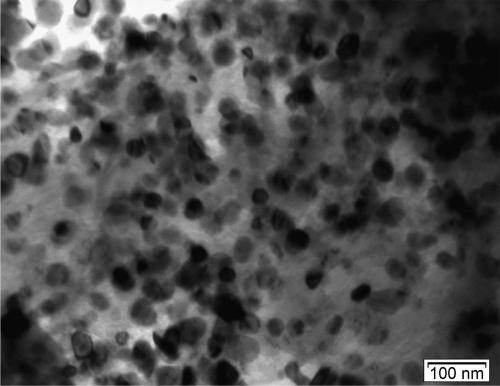

[0036] Step 1. Ball milling treatment: take 500mg of rGO and place it in a planetary ball mill for ball milling treatment. The mass of the balls is 25g, the speed is set at 500r / min, and the milling time is 3h.

[0037] Step 2, take rGO400mg of ball milling 3h, take Ni(CH 3 COO) 2 4H 2 O powder 830mg, uniformly mixed in a planetary ball mill, and the mixture was passed through N 2 Heating in an atmosphere tube furnace at 500°C for 2h with a gas flow rate of 900mL / min, cooling with the furnace to obtain Ni-rGO.

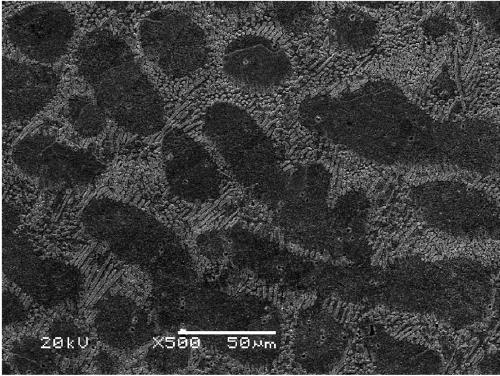

[0038]Step 3. Weigh 99.99g of Sn2.5Ag0.7Cu0.1RE solder powder with a particle size of 25-40μm; take a certain amount of Ni-rGO and ultrasonically treat it in alcohol solution for 30min, then mix it with Sn2.5Ag0.7Cu0.1RE The solder powder is mixed, and the mass fraction of Ni-rGO added is 0.01wt.%.

[0039] Step 4: Pour the mixture of Sn2.5Ag0.7Cu0.1RE solder powder and Ni-rGO in step 3 into a drum-type ball mill tank, set the rotation speed to 100r / min, and ball m...

Embodiment 2

[0042] Step 1. Ball milling treatment: take 500mg of rGO and place it in a planetary ball mill for ball milling treatment. The mass of the balls is 25g, the speed is set at 500r / min, and the milling time is 3h.

[0043] Step 2, take rGO400mg of ball milling 3h, take Ni(CH 3 COO) 2 4H 2 O powder 830mg, uniformly mixed in a planetary ball mill, and the mixture was passed through N 2 Heating in an atmosphere tube furnace at 500°C for 2h with a gas flow rate of 900mL / min, cooling with the furnace to obtain Ni-rGO.

[0044] Step 3. Weigh 99.99g of Sn2.5Ag0.7Cu0.1RE solder powder with a particle size of 25-40μm; take a certain amount of Ni-rGO and ultrasonically treat it in alcohol solution for 30min, then mix it with Sn2.5Ag0.7Cu0.1RE The solder powder is mixed, and the mass fraction of Ni-rGO added is 0.03wt.%.

[0045] Step 4: Pour the mixture of Sn2.5Ag0.7Cu0.1RE solder powder and Ni-rGO in step 3 into a drum-type ball mill tank, set the rotation speed to 100r / min, and ball ...

Embodiment 3

[0048] Step 1. Ball milling treatment: take 500mg of rGO and place it in a planetary ball mill for ball milling treatment. The mass of the balls is 25g, the speed is set at 500r / min, and the milling time is 3h.

[0049] Step 2, take rGO400mg of ball milling 3h, take Ni(CH 3 COO) 2 4H 2 O powder 830mg, uniformly mixed in a planetary ball mill, and the mixture was passed through N 2 Heating in an atmosphere tube furnace at 500°C for 2h with a gas flow rate of 900mL / min, cooling with the furnace to obtain Ni-rGO.

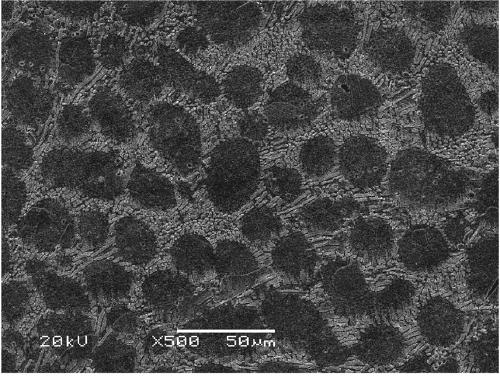

[0050] Step 3. Weigh 99.99g of Sn2.5Ag0.7Cu0.1RE solder powder with a particle size of 25-40μm; take a certain amount of Ni-rGO and ultrasonically treat it in alcohol solution for 30min, then mix it with Sn2.5Ag0.7Cu0.1RE The solder powder is mixed, and the mass fraction of Ni-rGO added is 0.05wt.%.

[0051] Step 4: Pour the mixture of Sn2.5Ag0.7Cu0.1RE solder powder and Ni-rGO in step 3 into a drum-type ball mill tank, set the rotation speed to 100r / min, and ball ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com