Latex paper and its preparation method

A technology of latex paper and weight percentage, applied in the field of papermaking, can solve the problems of weak sand planting, poor water resistance, low strength, etc., and achieve the effects of scientific and reasonable operation, good water resistance and firm bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

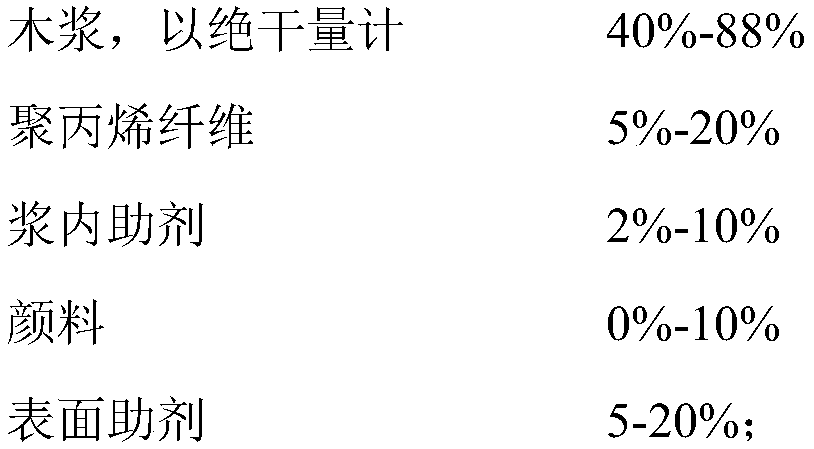

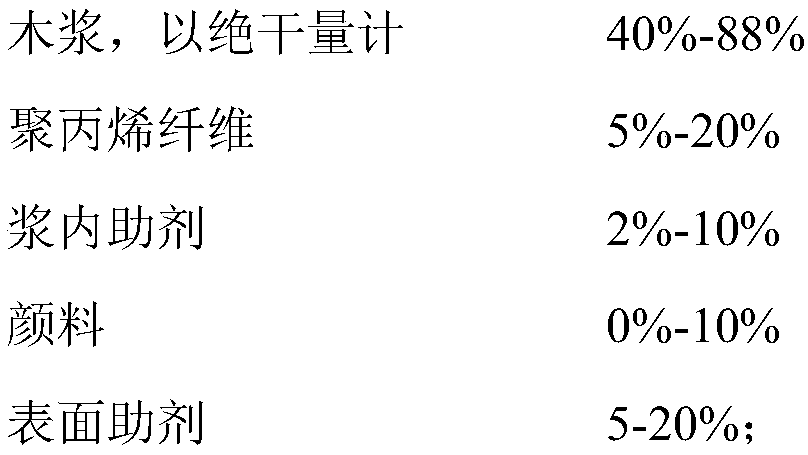

Method used

Image

Examples

Embodiment 1

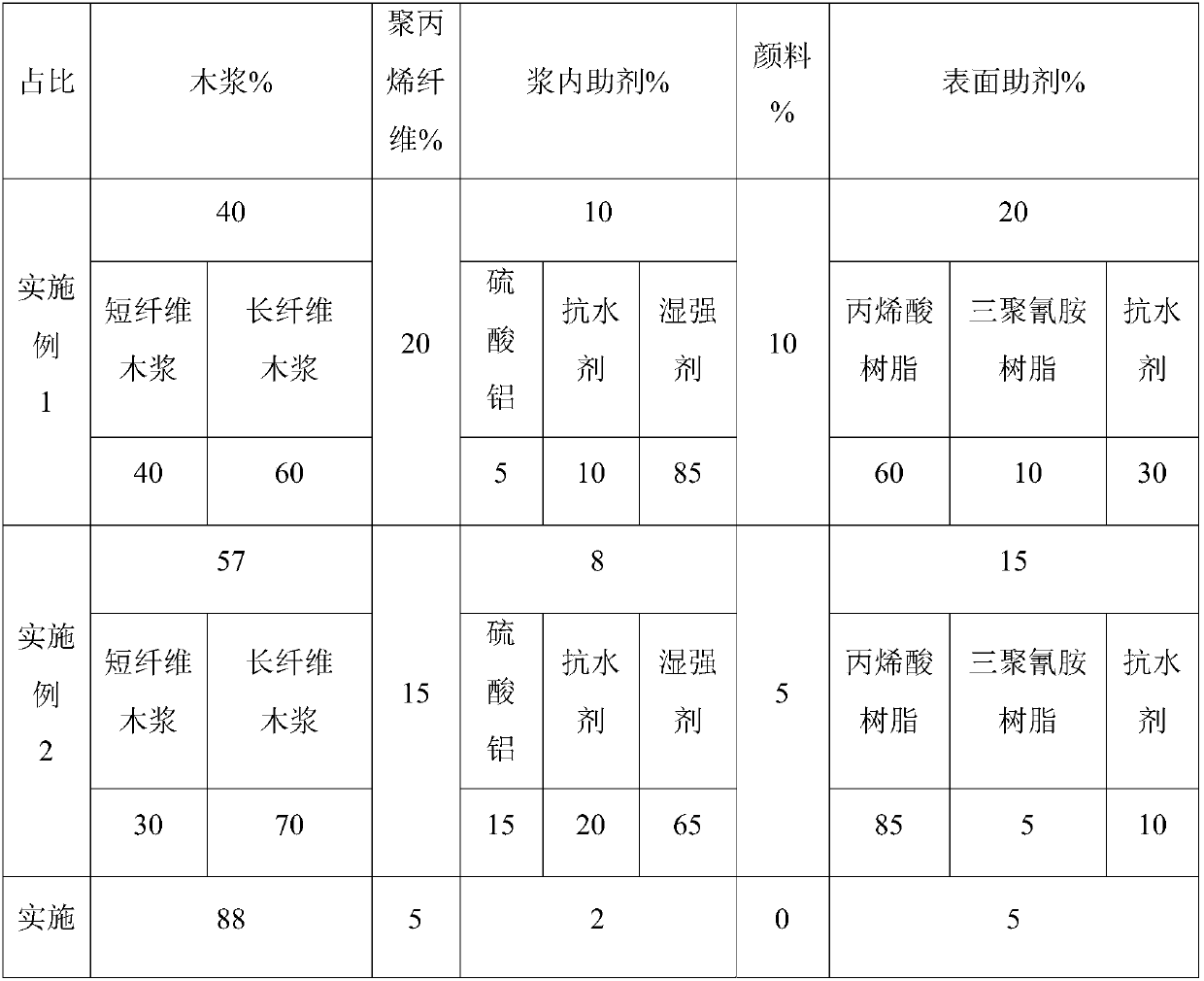

[0043] Latex paper raw material proportion described in embodiment 1 is described in table 1, wherein:

[0044] The wet strength agent is polyamide-epichlorohydrin resin, provided by Chengguang Wet Strength Agent.

[0045] The pigment is Iron Oxide Yellow 4910.

[0046] The fiber diameter of polypropylene fiber is 25 microns, and the density is 0.91g / cm 3 , acid and alkali resistance is 95%.

[0047] The acrylic resin is a thermoplastic latex solution with a glass transition temperature Tg value of -28°C provided by Handan Ruistar Latex Technology Co., Ltd. to improve the softness of the latex paper.

[0048] The anti-water agent is AKD new neutral sizing agent provided by Longyuan Chemical Factory, a cationic white emulsion with a solid content of 12.5%.

[0049] The preparation method of latex paper described in embodiment 1 specifically comprises the following steps:

[0050] (1) Wood pulp is hydrolyzed according to the ratio in Example 1, the pulping concentration is 2...

Embodiment 2

[0058] Latex paper raw material proportion described in embodiment 2 is described in table 1, wherein:

[0059] The wet strength agent is polyamide-epichlorohydrin resin, provided by Chengguang Wet Strength Agent.

[0060] The pigment is iron oxide red and black 4330.

[0061] The fiber diameter of polypropylene fiber is 30 microns, and the density is 0.91g / cm 3 , 95% acid and alkali resistance.

[0062] The acrylic resin is a thermoplastic latex solution with a glass transition temperature Tg value of -25°C provided by Handan Ruistar Latex Technology Co., Ltd. to improve the softness of the latex paper.

[0063] The anti-water agent is AKD new neutral sizing agent provided by Longyuan Chemical Factory, a cationic white emulsion with a solid content of 12.5%.

[0064] The preparation method of latex paper described in embodiment 2 specifically comprises the following steps:

[0065] (1) Carry out hydraulic disintegration to wood pulp according to embodiment 2, pulp concentra...

Embodiment 3

[0073] Latex paper raw material proportion described in embodiment 3 is described in table 1, wherein:

[0074] The wet strength agent is polyamide-epichlorohydrin resin, provided by Chengguang Wet Strength Agent.

[0075] The fiber diameter of polypropylene fiber is 35 microns, and the density is 0.91g / cm 3 , 95% acid and alkali resistance.

[0076] The acrylic resin is a thermoplastic latex solution with a glass transition temperature Tg value of -28°C provided by Handan Ruistar Latex Technology Co., Ltd. to improve the softness of the latex paper.

[0077] The anti-water agent is AKD new neutral sizing agent provided by Longyuan Chemical Factory, a cationic white emulsion with a solid content of 12.5%.

[0078] The preparation method of latex paper described in embodiment 3 specifically comprises the following steps:

[0079] (1) Carry out hydraulic disintegration to wood pulp according to the proportioning in embodiment 3, pulp concentration 4%, squeeze into the pulp ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com