Preparation method of porous carbon-supported nitrogen-containing bimetallic catalyst and electrochemical application thereof

A bimetallic catalyst and supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., to achieve good electrical conductivity, increase particle stability, and improve particle activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 340 mg of copper nitrate trihydrate and 480 mg of triethylenediamine to 15 mL of N, N-dimethylformamide (DMF), and drop into 10 mL of terephthalic acid that is 70 g / L pre-configured and dissolved in DMF, And 15mL of pre-configured palladium acetylacetonate solution dissolved in DMF with a concentration of 6g / L, mixed and stirred;

[0033] (2) Take 1.0 g of ordered mesoporous carbon material, add it to the mixed solution obtained in step (1), and stir evenly;

[0034] (3) Place the homogeneous system obtained in step (2) in a hydrothermal kettle, heat in an oven at 150°C, react for 24 hours, filter, wash with DMF three times, and dry;

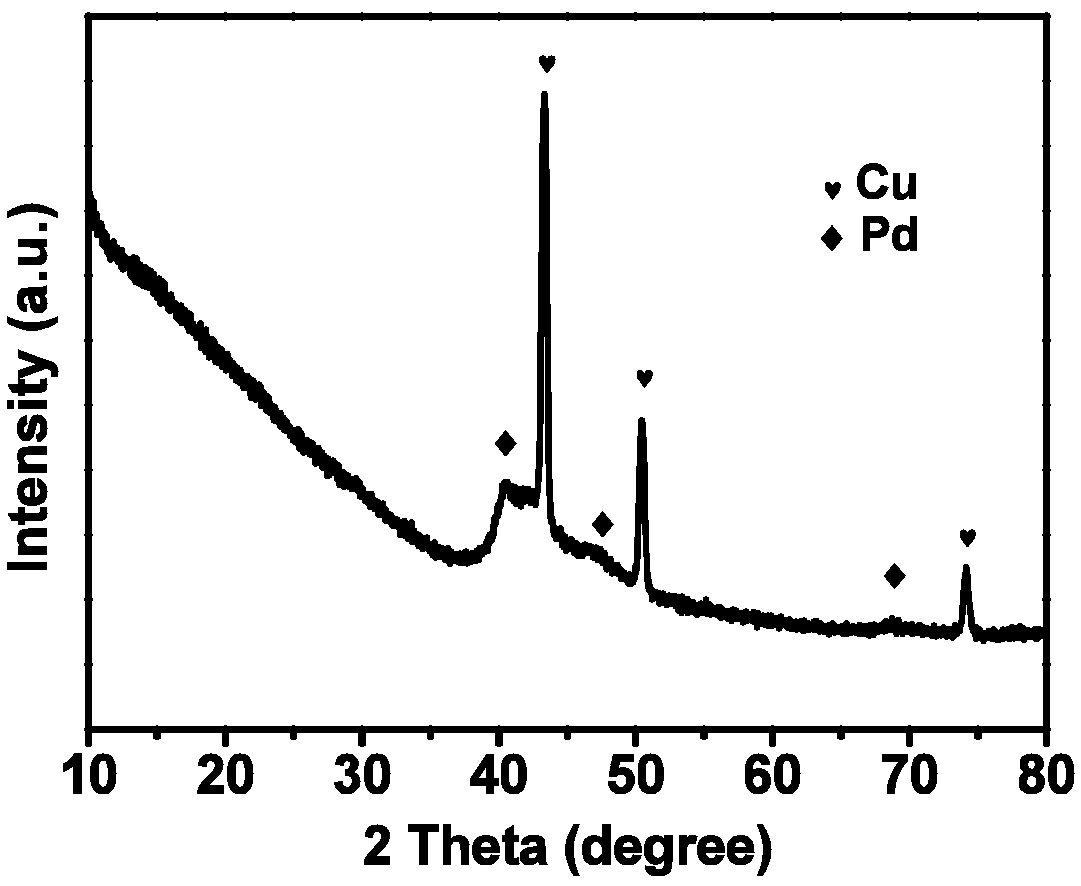

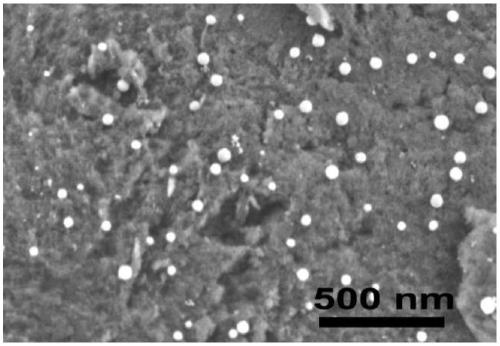

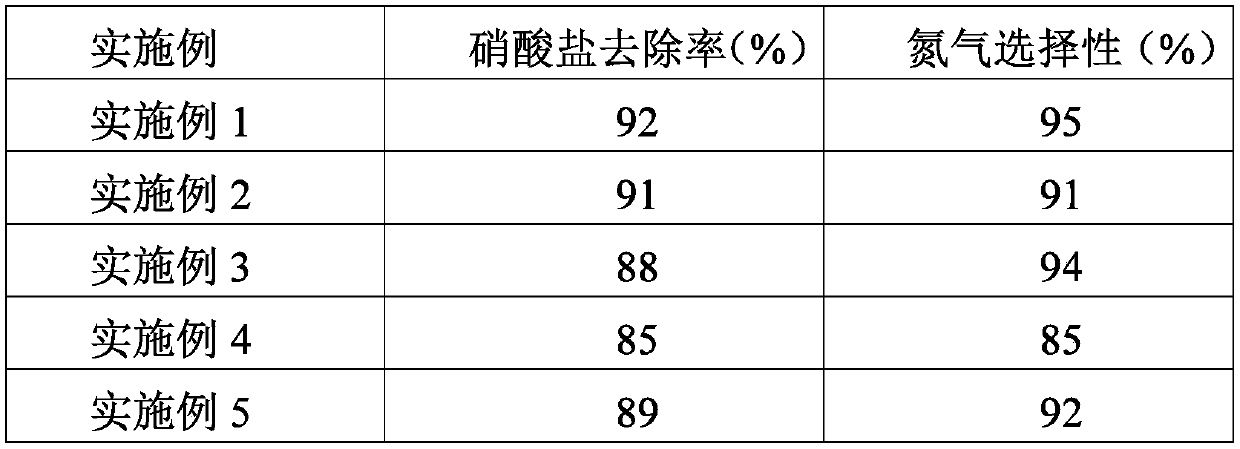

[0035] (4) Place the material obtained after step (3) drying in a tube furnace with a nitrogen atmosphere, and bake at 800°C for 2h to obtain a mesoporous carbon-supported nitrogen-containing copper-palladium bimetallic catalyst; the prepared mesoporous carbon-supported The XRD spectrum of the nitrogen-containing bimetallic catal...

Embodiment 2

[0039] The preparation method of porous carbon-supported nitrogen-containing bimetallic catalyst and its electrochemical application are as in Example 1. The difference is that in the catalyst preparation process, the addition of ordered mesoporous carbon is 0.8g, and the concentration of palladium acetylacetonate solution is 4.8g / L. The properties of the obtained electrocatalytic reduction of nitrate are shown in Table 1.

Embodiment 3

[0041] The preparation method of the porous carbon-supported nitrogen-containing bimetallic catalyst and its electrochemical application are as in Example 1, except that during the preparation of the catalyst, it is heated in an oven at 120° C. for 48 hours. The properties of the obtained electrocatalytic reduction of nitrate are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com