Photocatalytic gel material and preparation method thereof

A gel material and photocatalytic technology, applied in the field of photocatalytic materials, can solve the problems that photocatalytic materials cannot be used, achieve good photochemical stability, short preparation time, and facilitate large-scale industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

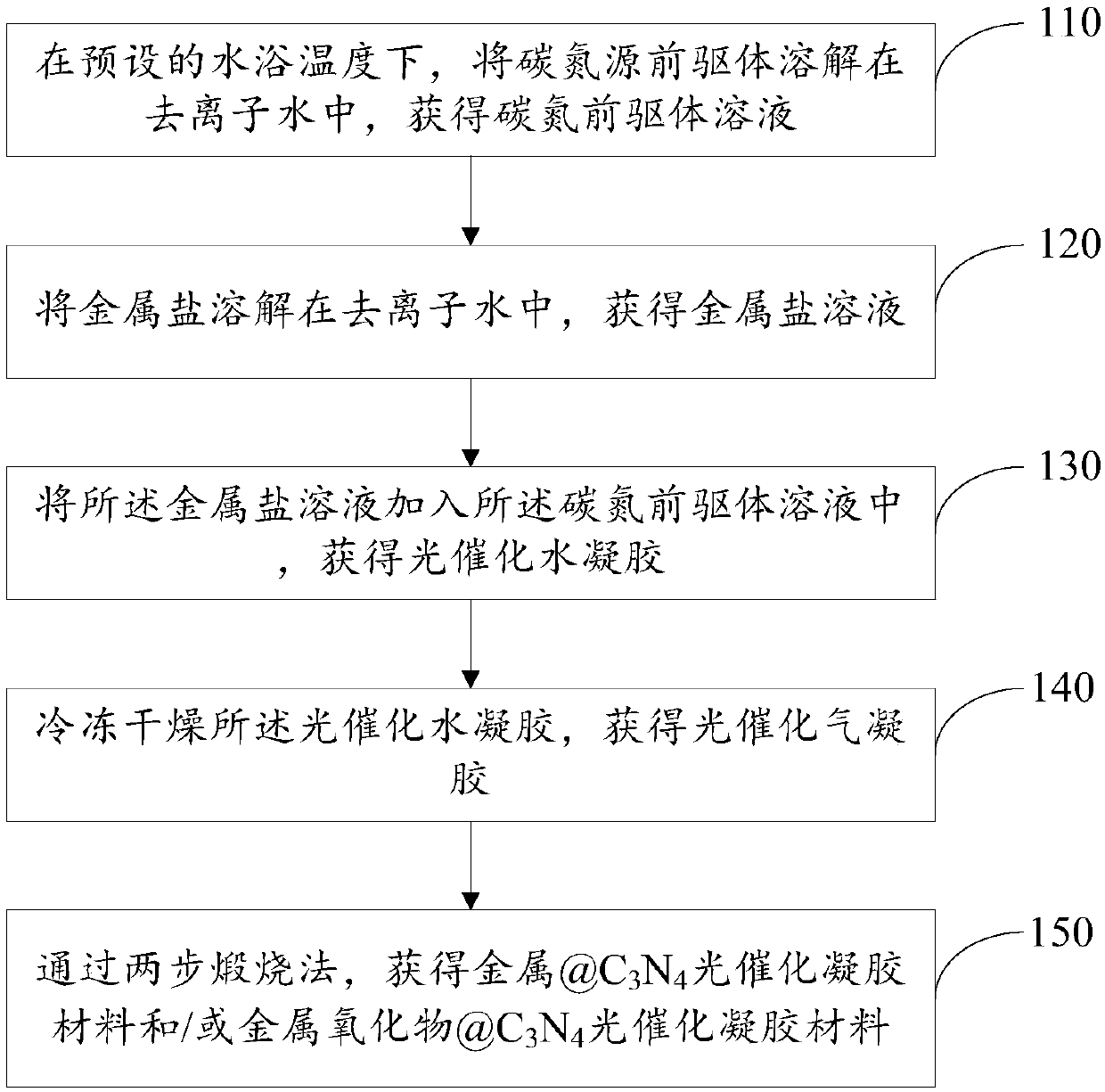

preparation example Construction

[0032] Photocatalytic gel materials are photocatalytically active materials that can produce a large number of strong oxidants under the excitation of light energy to achieve functions such as cleaning the environment and antibacterial. figure 1 It is a flow chart of the preparation method of the photocatalytic gel material provided by the embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0033] 110. Dissolving the carbon and nitrogen source precursor in deionized water at a preset water bath temperature to obtain a carbon and nitrogen precursor solution.

[0034] In order to ensure that the carbon and nitrogen source precursor can be fully dissolved in deionized water to form a stable solution, it can be added in a water bath to provide a stable temperature. In some embodiments, the preset temperature of the water bath can be controlled at 30 to 50° C. to ensure that the carbon and nitrogen sources can be fully dissol...

Embodiment 1

[0057] 1) Under the condition of magnetic stirring, 5 mL of copper sulfate solution (concentration of 0.8 mol / L) was quickly added to 10 mL of dicyandiamide (concentration of 0.4 mol / L) to obtain a hydrogel material.

[0058] 2) Put the hydrogel material into a freeze dryer to freeze-dry to obtain the following: image 3 As shown, the airgel material has a certain hardness and is well formed.

[0059] 3) Put the airgel material prepared in step 2) into a polytetrafluoroethylene reactor and seal it, heat at 160°C for 3 hours, and then continue heating at 180°C for 1 hour to obtain a preheated airgel material.

[0060] 4) Calcining the preheated airgel material at 550°C for 4 hours in an argon atmosphere to obtain CuO@g-C3N4 photocatalytic airgel material.

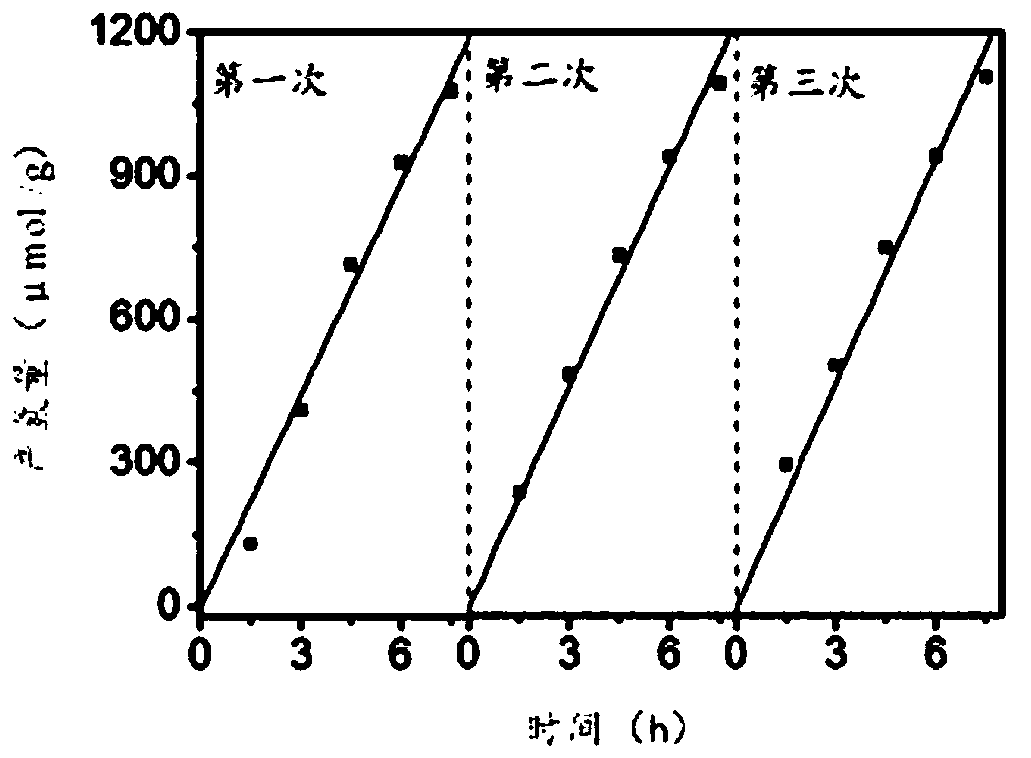

[0061] 5) For CuO@g-C 3 N 4 Photocatalytic airgel material for photocatalytic antibacterial activity test:

[0062] First, the CuO@g-C 3 N 4 After the photocatalytic airgel material was ground into powder, it was added...

Embodiment 2

[0066] 1) Under the condition of magnetic stirring, 5 mL of copper sulfate solution (concentration of 1 mol / L) was quickly added to 10 mL of dicyandiamide (concentration of 0.4 mol / L) to obtain a hydrogel material.

[0067] 2) Putting the hydrogel material into a freeze dryer to freeze-dry to obtain the airgel material.

[0068] 3) Put the airgel material prepared in step 2) into a polytetrafluoroethylene reactor, seal it, and heat it at 160°C for 3 hours, and at 180°C for 1 hour to obtain a preheated airgel material.

[0069] 4) Calcinate the preheated airgel material at 550°C for 4 hours in an argon atmosphere to obtain CuO@g-C 3 N 4 Photocatalytic airgel materials.

[0070] 5) For CuO@g-C 3 N 4 Photocatalytic airgel material for photocatalytic antibacterial activity test:

[0071] First, the CuO@g-C 3 N 4 After the photocatalytic airgel material was ground into powder, it was added to the sample bag of the bacterial culture medium. Then, place the sample bag contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com