General suspension granulation method for preparing sintered metal-graphite composite

A technology for sintering metal and composite materials, applied in metal processing equipment, transportation and packaging, etc., can solve problems affecting the mechanical properties of materials, graphite layer slippage, hindering the sintering and diffusion process of metal-metal particles, etc., and achieve strong versatility , uniform density and uniform phase distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

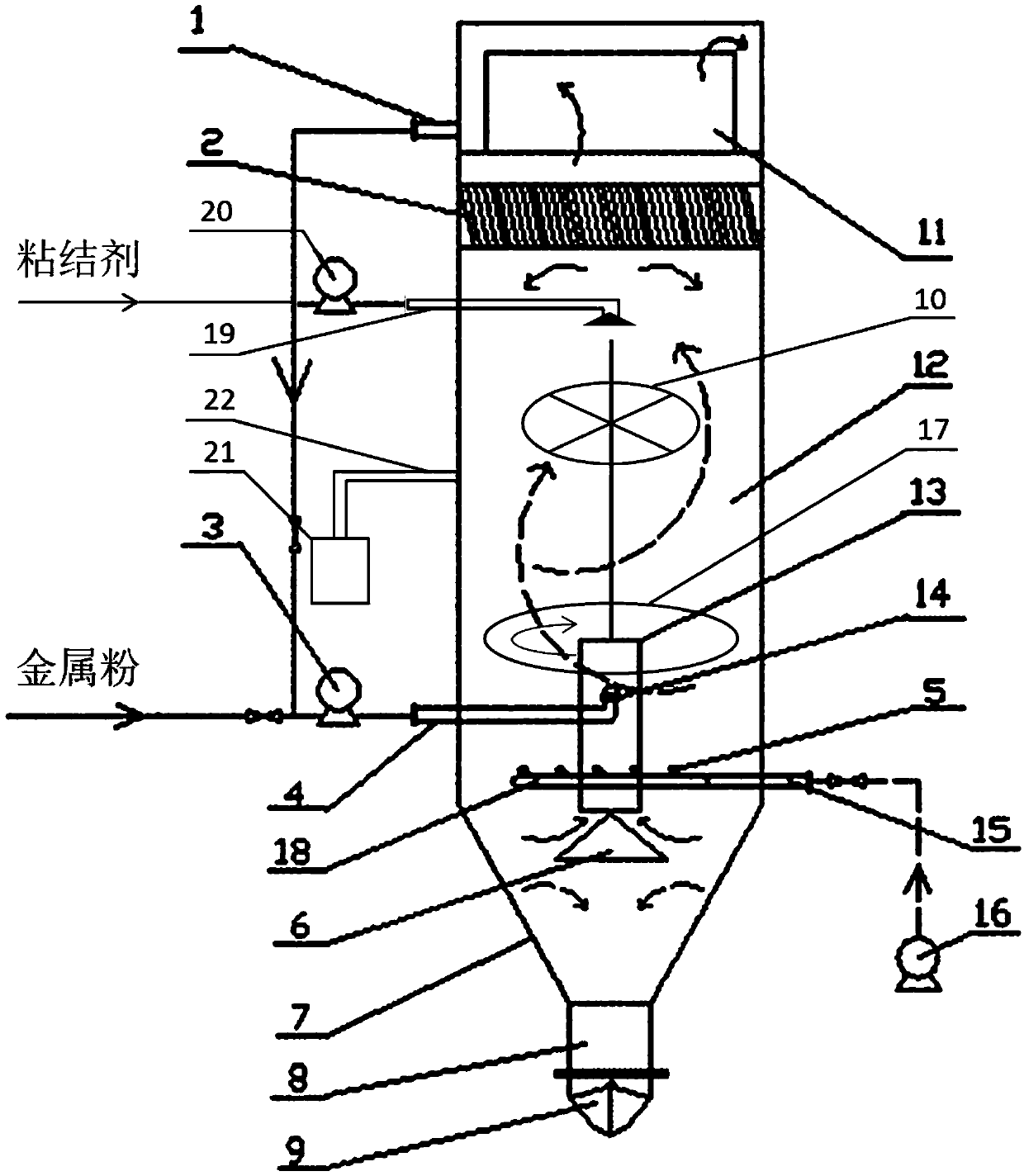

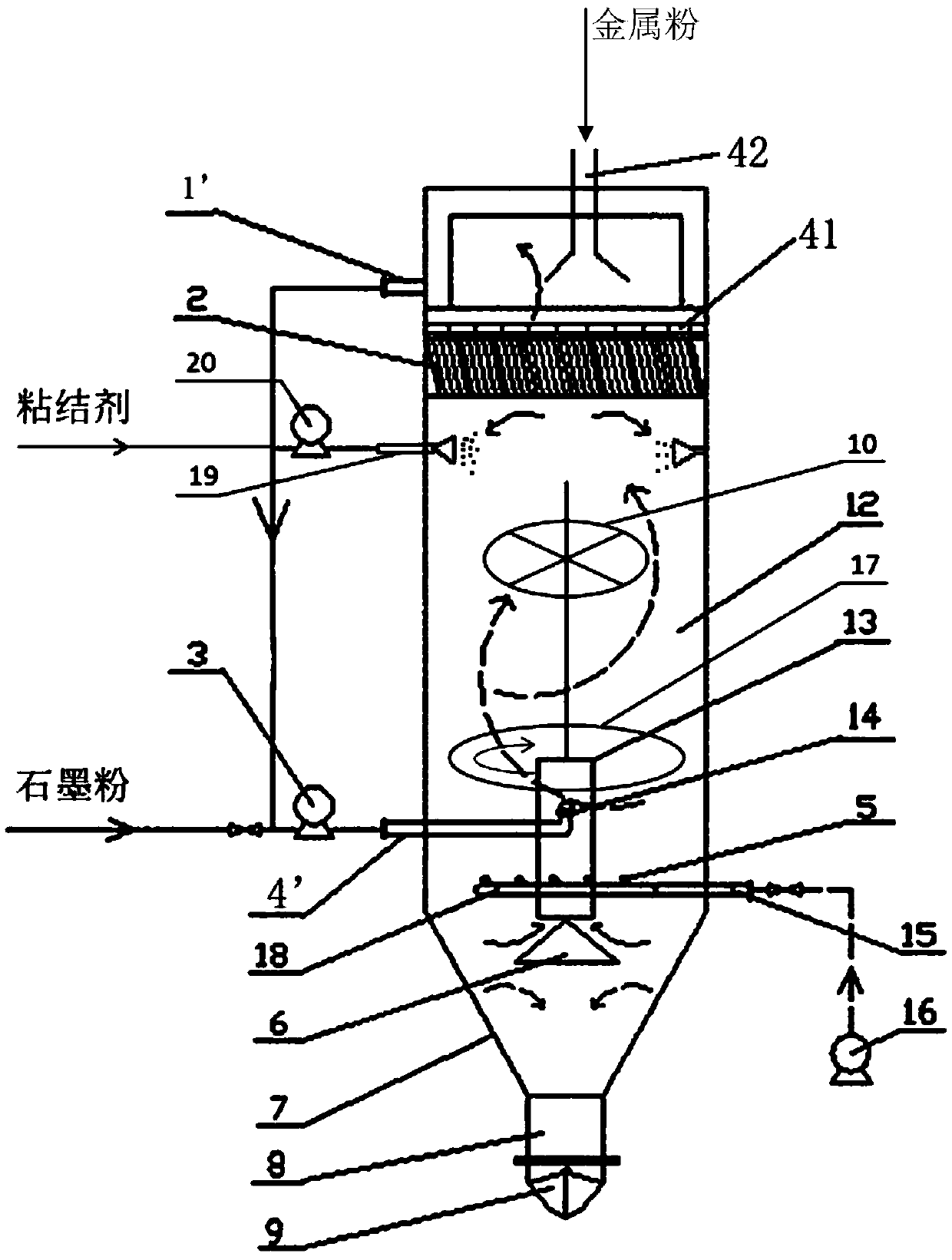

Method used

Image

Examples

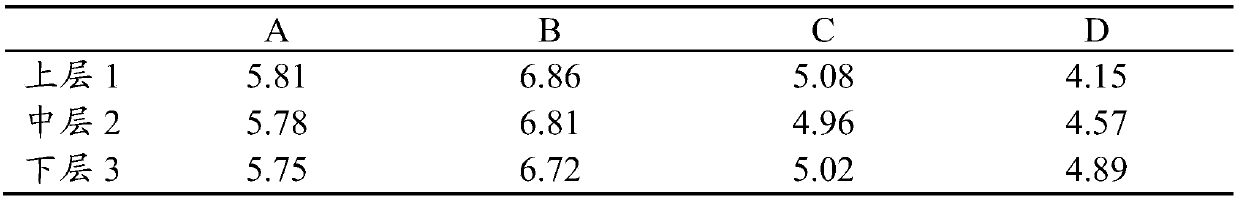

Embodiment 1

[0059] S1: Suspend 1000 g of flake graphite powder with a particle size of 400-550 μm in 6 L of Midi Glatt type fluidized bed airflow; the fluidization gas is dry air, the temperature is 15 ° C, and the fluidization pressure is 0.45 Bar.

[0060] S21: Introduce the binder solution by top spraying, the binder is polyvinyl alcohol, and the spray rate is 2.1g / min.

[0061] S22: Introduce metal powder by tangential spraying method, the metal powder is a mixed powder of copper (18-48 μm), iron (23-75 μm) and ferrochromium (80-230 μm), the weight ratio is 80 / 15 / 5, and the flow rate is controlled. 92g / min.

[0062] Wherein, step S22 is performed simultaneously with step S21.

[0063] S3: Control fluidization time to 1.6h. The pretreated powder thus obtained was dried to obtain a composite powder A.

Embodiment 2

[0065] S1: Suspend 500g of artificial graphite and expanded graphite mixed powder with a particle size of 200-350μm (weight ratio: 1:1) in 4.4L of Midi Glatt type fluidized bed airflow; the fluidization gas is dry air at a temperature of 25°C , fluidization pressure 0.27Bar.

[0066] S21: Introduce the binder solution by top spraying, the binder is polyvinyl alcohol, and the spray rate is 1.8g / min.

[0067] S22: Introduce metal powder by tangential spraying method, the metal powder is a mixed powder of copper (4-10μm), iron (10-18μm) and nickel (23-45μm), the weight ratio is 63 / 24 / 13, and the flow rate is 110g / min.

[0068] Wherein, step S22 lags behind step S21 by about 5s˜60s.

[0069] S3: Control the fluidization time to 0.8h. The pretreated powder thus obtained was dried to obtain a composite powder B.

Embodiment 3

[0071] S1: Suspend 800 g of artificial graphite powder with a particle size of 300-450 μm in 3.75 L of Midi Glatt type fluidized bed airflow; the fluidization gas is dry air, the temperature is 20 ° C, and the fluidization pressure is 0.38 Bar.

[0072] S21: Introduce the binder solution by top spraying, the binder is polyvinyl alcohol, and the spray rate is 0.75g / min.

[0073] S22: Introduce metal powder by tangential spraying, the metal powder is a mixed powder of copper (10-25μm), iron (13-45μm) and chromium (48-75μm), the weight ratio is 72 / 20 / 8, and the flow rate is 62g / min.

[0074] Wherein, step S22 is performed simultaneously with step S21.

[0075] S3: Control fluidization time to 1.2h. The pretreated powder thus obtained was dried to obtain a composite powder C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com