Preparation method of nano layered clinoptilolite molecular sieve

A clinoptilolite and nano-layered technology is applied in the field of preparation of zeolite molecular sieve materials and can solve the problems of low crystallinity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Add 0.7362g of aluminum hydroxide, 0.5192g of sodium hydroxide and 0.7268g of potassium hydroxide into 25ml of deionized water, stir at 150°C for 2h until it becomes clear, then add 8.8ml of silica sol, stir well to obtain solution I .

[0023] (2) Mix and stir 0.7362g aluminum hydroxide, 0.5192g sodium hydroxide, 0.7268g potassium hydroxide, 8.8ml silica sol and 25ml deionized water for 30 minutes, then stir and age at 150°C for 60h, and cool to room temperature The solution II obtained by filtration is used as a structure promoter for future use.

[0024] (3) Add 3ml of solution II into solution I, and stir well to obtain a uniform sol. The above sol was transferred into a high-pressure reactor and crystallized at 150°C for 48h.

[0025] (4) Take the kettle, cool it to room temperature, filter and wash the crystallized product with 80% ethanol solution, and dry it at 150° C. for 12 hours to obtain nano-layered clinoptilolite molecular sieve.

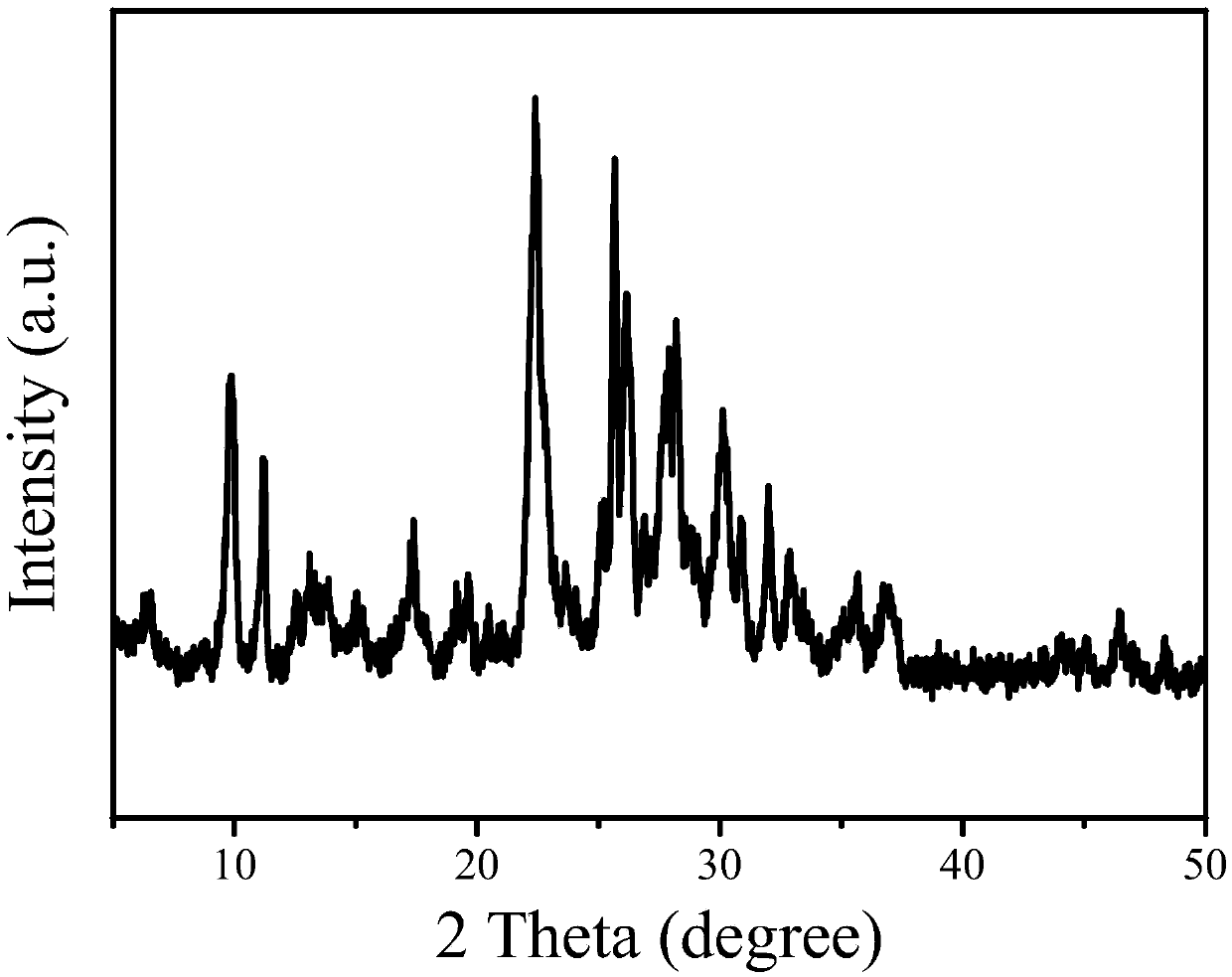

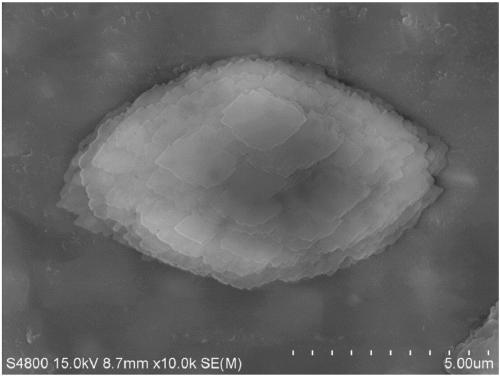

[0026] (5) X-ray ...

Embodiment 2

[0028] (1) The preparation of solution I is as in Example 1.

[0029] (2) Mix and stir 3.681g aluminum hydroxide, 2.596g sodium hydroxide, 3.634g potassium hydroxide, 44ml silica sol and 125ml deionized water for 30 minutes, then stir and age at 150°C for 6h, cool to room temperature and filter Solution II is obtained as a structure promoter for later use.

[0030] (3) Add 1ml of solution II into solution I and stir well to obtain a uniform sol. The above sol was transferred into a high-pressure reactor, and crystallized at 180° C. for 24 hours.

[0031] (4) Take the kettle, cool to room temperature, filter and wash the crystallized product with ethanol solution with a mass fraction of 50%, and dry at 150° C. for 12 hours to obtain nano-layered clinoptilolite molecular sieve.

Embodiment 3

[0033] (1) Add 0.4813g of alumina, 0.5192g of sodium hydroxide and 0.7268g of potassium hydroxide into 25ml of deionized water, stir at 120°C for 3h until clear, then add 10.56g of white carbon black, stir well to obtain solution I .

[0034] (2) Mix and stir 0.4813g alumina, 0.5192g sodium hydroxide, 0.7268g potassium hydroxide, 10.56g white carbon black and 25ml deionized water for 40 minutes, then stir and age at 150°C for 60h, and cool to room temperature The solution II obtained by filtration is used as a structure promoter for future use.

[0035] (3) Add 6ml of solution II into solution I, and stir well to obtain a uniform sol. The above sol was transferred into an autoclave for crystallization at 180°C for 15 hours.

[0036] (4) Take the kettle, cool to room temperature, filter and wash the crystallized product with ethanol solution with a mass fraction of 60%, and dry at 200°C for 10 hours to obtain nano-layered clinoptilolite molecular sieve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com