Preparation method of composite biological organic fertilizer granule

A bio-organic fertilizer and granule technology is applied in the preparation of organic fertilizers, the treatment of bio-organic parts, and organic fertilizers. It can solve the problems of reducing fertilizer efficiency, difficult to decompose crude fibers, and reducing the content of small molecule sugars in organic fertilizers. Achieve the effects of improving fertilizer efficiency, improving granulation efficiency, and uniform granulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of compound bio-organic fertilizer granules, the specific preparation process is as follows:

[0032] In the first step, the crude fiber-degrading bacteria are added to the rice bran and mixed evenly to make a fermented material, then the corn stalk, wheat straw and rice husk are crushed and mixed, and the fermented material is added to it, and water is sprayed on it while stirring and mixing. Keep the humidity of the mixture at 55%-60%, then ferment at 37-40°C for 15 days, keep turning the mixture every day, so that the mixture contains enough oxygen to meet the requirements of crude fiber-degrading bacteria on straw and rice husk degradation;

[0033]In the second step, the materials degraded in the first step, animal manure, bean cake, and biogas residue are added to the fermenter, and aerobic fermentation is carried out at 35-38°C for 5 days, and then calcium chloride is added to the fermenter, and mixed evenly. The fermentation tank is sealed ...

Embodiment 2

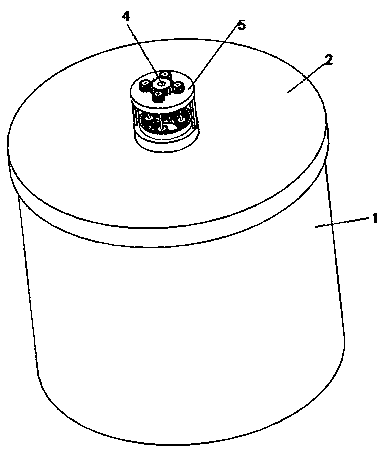

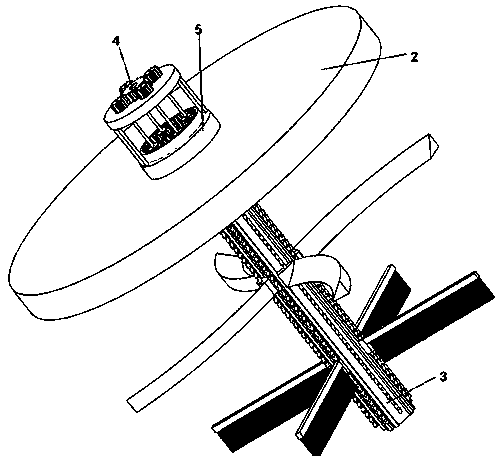

[0036] Such as Figure 1-3 As shown, the self-adjusting homogeneous granulator includes a filter barrel 1 and a sealing cover 2 installed and fixed on the top of the filter barrel 1; a rotating seat 5 is installed at the center of the surface of the sealing cover 2, and a crushing and sweeping mechanism is installed under the rotating seat 5 3. An adjustment mechanism 4 is installed above the rotating seat 5;

[0037] A number of filter holes are evenly opened at the bottom of the filter barrel 1;

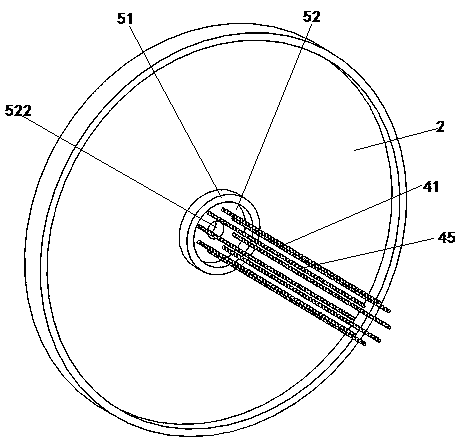

[0038] Such as Figure 4-6 As shown, there is a first mounting hole at the center of the surface of the sealing cover 2, and the rotating seat 5 is installed in the first mounting hole, and the sixth bearing is installed in the first mounting hole, and the rotating seat 5 includes a bearing installed in the sixth bearing. Positioning ring 51, the middle part of the inner surface of the side wall of positioning ring 51 is integrally connected and fixed with mounting block 52, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com