Disposal method and system of by-product tail gas for production of tetrachloroethylene

A technique for treating tetrachlorethylene, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problems of cumbersome steps, high consumption, and low temperature, and achieve simple steps, low cost, and reduced consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

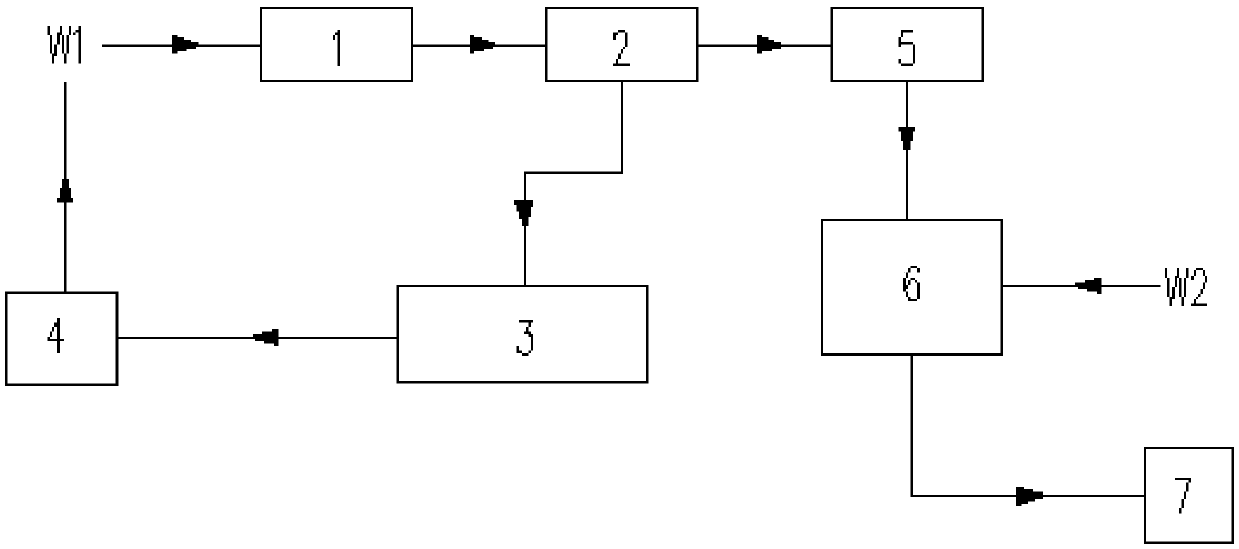

[0028] A treatment system for producing tetrachlorethylene by-product tail gas, such as figure 1 Shown, comprise: compression system 1, condensation system 2, carbon tetrachloride storage tank 3 and thermal chlorination reaction system (comprising preheater 5 and thermal chlorination reactor 6, preheater 5 and thermal chlorination reactor 6 are connected in sequence); the compression system 1, the condensation system 2, the carbon tetrachloride storage tank 3 are connected in sequence by pipelines, the carbon tetrachloride storage tank 3 is connected with the tetrachlorethylene production system 4 by the circulation device, and the tetrachloride The ethylene production system 4 is connected to the compression system 1 through pipelines; the condensing system 2 is also connected to the preheater 5 through pipelines; the thermal chlorination reactor 6 is connected to the hydrochlorination reaction system 7 through a condensing device.

[0029] The compression system 1, condensat...

Embodiment 2

[0031] Utilize the processing system described in embodiment 1 to process the method for producing tetrachlorethylene by-product tail gas, comprise main components in the production tetrachlorethylene by-product tail gas that comes out from tetrachlorethylene production system 4: hydrogen chloride 80.3%wt, chlorine and tetrachloride Carbon 10.2%wt.

[0032] The by-product tail gas W1 from the production of tetrachlorethylene enters the compression system 1, is compressed to 1.0MPa, and then enters the condensation system 2, and the condensation temperature is -10°C; after condensation, liquid carbon tetrachloride and mixed gas (carbon tetrachloride in the mixed gas content is 1wt%); liquid carbon tetrachloride enters carbon tetrachloride storage tank 3, returns to tetrachlorethylene production system 4 through circulation device and continues to participate in the preparation of tetrachlorethylene; gained mixed gas main component after condensation is: 85.3%wt Hydrogen chlorid...

Embodiment 3

[0034] Utilize the processing system described in embodiment 1 to process the method for producing tetrachlorethylene by-product tail gas, comprise main components in the production tetrachlorethylene by-product tail gas that comes out from tetrachlorethylene production system 4: hydrogen chloride 80.3%wt, chlorine and tetrachloride Carbon 10.2%wt.

[0035]The by-product tail gas W1 from the production of tetrachlorethylene enters the compression system 1, is compressed to 1.2MPa, and then enters the condensation system 2, and the condensation temperature is -5°C; after condensation, liquid carbon tetrachloride and mixed gas (carbon tetrachloride in the mixed gas content is 1.6wt%); liquid carbon tetrachloride enters the carbon tetrachloride storage tank 3, returns to the tetrachlorethylene production system 4 and continues to participate in the preparation of tetrachlorethylene through the circulation device; the main component of the mixed gas obtained after condensation is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com