Method for preparing low molecular chitosan by gradient ultrasonic

A low-molecular-weight chitosan and gradient ultrasound technology, applied in the field of low-molecular-weight chitosan preparation, can solve the problems of unsuitable control of hydrolysis degree, wide product molecular weight distribution, long enzymatic production cycle, etc., and achieves safe and reliable degradation process, molecular weight The effect of narrow distribution and simple post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

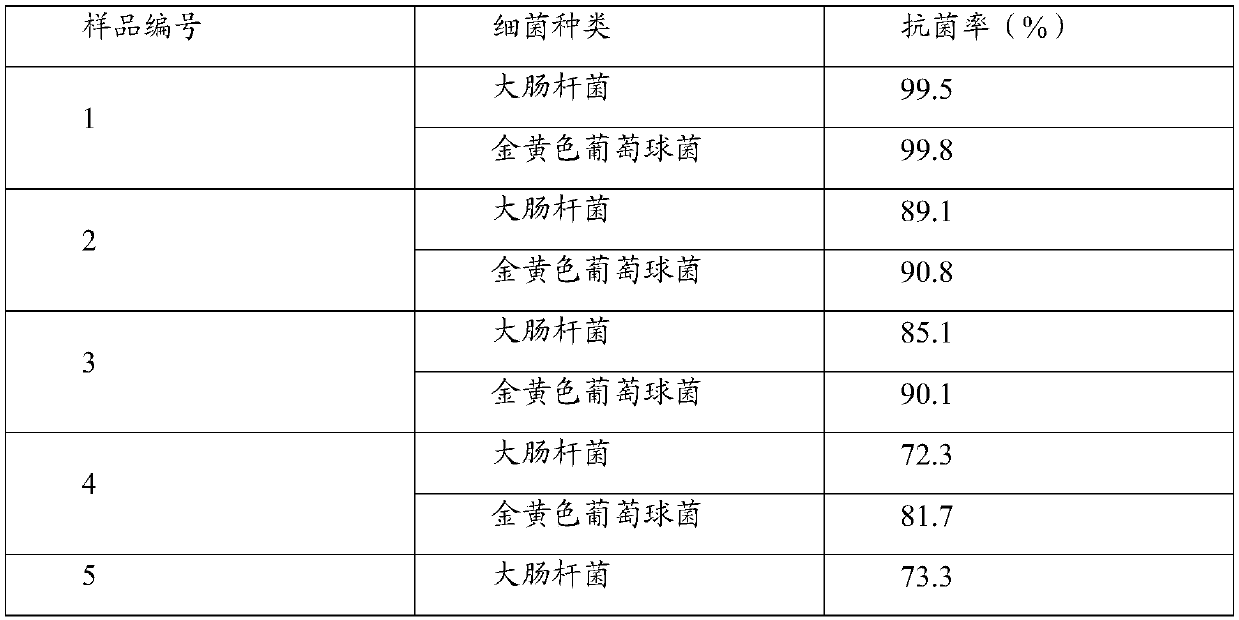

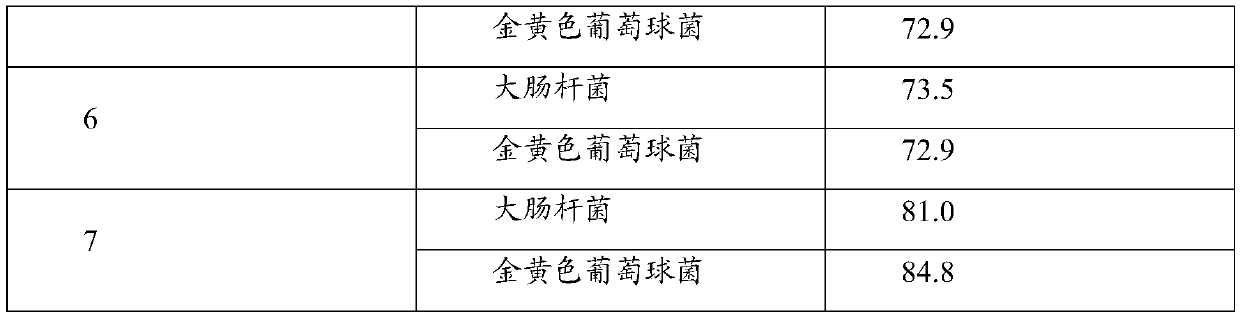

Embodiment 1

[0019] A kind of method of the present invention prepares low-molecular chitosan with gradient ultrasonic, comprises the following steps:

[0020] (1) Dissolution of high molecular weight chitosan: dissolving high molecular weight chitosan with a molecular weight of 10kDa to 200kDa in an acetic acid solution with a volume fraction of 0.1% to 10% to obtain a chitosan solution with a volume fraction of 0.5% to 30% ;

[0021] Preferably, the molecular weight of high molecular weight chitosan is 50kDa, the volume fraction of acetic acid is 1%, and the volume fraction of chitosan solution is 16%;

[0022] (2) Degradation of high-molecular-weight chitosan: the chitosan solution obtained in step (1) is subjected to ultrasonic treatment three times, and the first ultrasonic treatment sets the ultrasonic temperature to 5~30° C. The duration is 2-6 hours, and the ultrasonic power is 150-300W; the ultrasonic temperature is set at 10-50°C for the second ultrasonic treatment, and the time...

Embodiment 2

[0028] A kind of method of the present invention prepares low-molecular chitosan with gradient ultrasonic, comprises the following steps:

[0029] (1) dissolving of high molecular weight chitosan: the high molecular weight chitosan that molecular weight is 100kDa is dissolved in the acetic acid solution that volume fraction is 5% is that volume fraction is 20% chitosan solution;

[0030] (2) Degradation of high-molecular-weight chitosan: the chitosan solution obtained in step (1) is subjected to three ultrasonic treatments, the first ultrasonic treatment sets the ultrasonic temperature to 20°C, and the ultrasonic power is 200W. 30 minutes, stop for 5 minutes, repeat this way, and the time from the beginning to the end of the first ultrasound is 2 hours. For the second ultrasonic treatment, the ultrasonic temperature was set at 40°C, and the ultrasonic power was 80W. During the ultrasonic treatment, every 30 minutes of ultrasonic treatment was followed by a 5-minute pause, and ...

Embodiment 3

[0034] A method for preparing low-molecular chitosan with gradient ultrasound, comprising the following steps:

[0035] (1) dissolving of high molecular weight chitosan: the high molecular weight chitosan that molecular weight is 200kDa is dissolved in the acetic acid solution that volume fraction is 1% is that volume fraction is 16% chitosan solution;

[0036](2) Degradation of high-molecular-weight chitosan: the chitosan solution obtained in step (1) is subjected to three ultrasonic treatments, the first ultrasonic treatment sets the ultrasonic temperature to 15°C, and the ultrasonic power is 200W. 30 minutes, stop for 5 minutes, repeat this way, the time from the beginning to the end of the first ultrasound is 6 hours. For the second ultrasonic treatment, the ultrasonic temperature was set at 20°C and the ultrasonic power was 80W. During the ultrasonic treatment, every 30 minutes of ultrasonic treatment was followed by a 5-minute pause, and this was repeated. The time from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap