SBS asphalt modifier, preparation method and application thereof

A technology of asphalt modifier and stabilizer, which is applied in the field of SBS asphalt modifier, can solve the problem of high requirements, achieve the effect of reducing production requirements and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

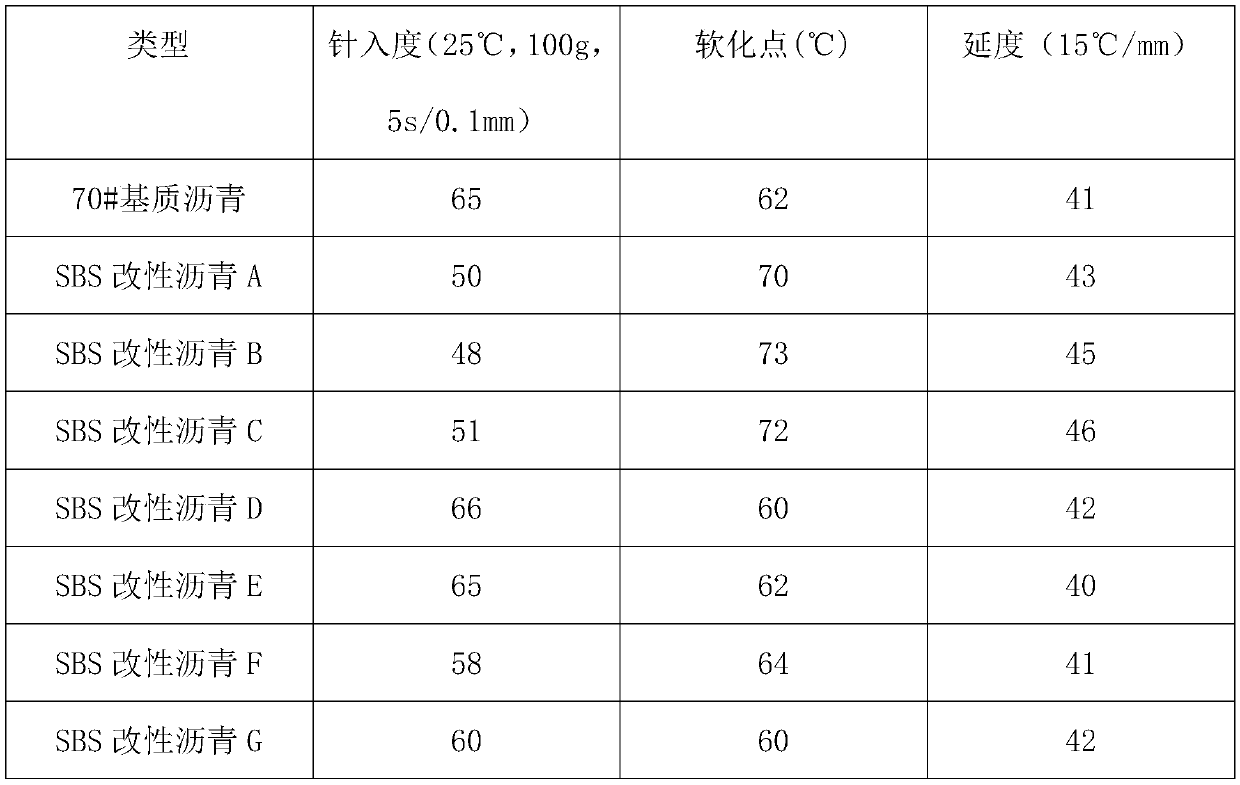

Embodiment 1

[0029] In the present embodiment, the preparation method of SBS asphalt modifier is as follows:

[0030] 1) Weigh the following parts by weight and material composition: 15 parts of SBS, 2 parts of stabilizer, 30 parts of oleic acid, and 20 parts of stearic acid; wherein, the stabilizer is composed of sucrose fatty acid and titanic acid;

[0031] 2) Heat the oleic acid to 100°C, stir at a speed of 40r / min for 10min, add the stearic acid in the above parts by weight, continue to stir for 5min, and heat to 140°C to obtain a disperse base for later use;

[0032] 3) Add SBS to the prepared dispersion base, and use a high-speed shearer to shear for 40 minutes at a shear rate of 3000r / min;

[0033] 4) After the high-speed shearing is completed, the mixture is stirred at a speed of 20 r / min, the above-mentioned stabilizer is added in parts by weight, stirred for 5 minutes, and naturally cooled to normal temperature to obtain the finished product of SBS asphalt modifier A, which is re...

Embodiment 2

[0036] In the present embodiment, the preparation method of SBS asphalt modifier is as follows:

[0037] 1) Weigh the following parts by weight and material composition: 15 parts of SBS, 2 parts of stabilizer, 33 parts of oleic acid, 17 parts of stearic acid; wherein, the stabilizer is composed of sucrose fatty acid and titanic acid;

[0038] 2) Heat the oleic acid to 100°C, stir at a speed of 40r / min for 10min, add the stearic acid in the above parts by weight, continue to stir for 5min, and heat to 140°C to obtain a disperse base for later use;

[0039] 3) Add SBS to the prepared dispersion base, and use a high-speed shearer to shear for 40 minutes at a shear rate of 3000r / min;

[0040] 4) After the high-speed shearing is completed, the mixture is changed to stirring at a speed of 20 r / min, the above-mentioned stabilizer is added in parts by weight, stirred for 5 minutes, and naturally cooled to normal temperature to obtain the finished product of SBS asphalt modifier B, whi...

Embodiment 3

[0043] In the present embodiment, the preparation method of SBS asphalt modifier is as follows:

[0044] 1) Weigh the following parts by weight and material composition: 15 parts of SBS, 2 parts of stabilizer, 2 parts of oleic acid, 18 parts of stearic acid; wherein, the stabilizer is composed of sucrose fatty acid and titanic acid;

[0045] 2) Heat the oleic acid to 100°C, stir at a speed of 40r / min for 10min, add the stearic acid in the above parts by weight, continue to stir for 5min, and heat to 140°C to obtain a disperse base for later use;

[0046] 3) Add SBS to the prepared dispersion base, and use a high-speed shearer to shear for 40 minutes at a shear rate of 3000r / min;

[0047] 4) After the high-speed shearing is completed, the mixture is changed to stir at a speed of 20 r / min, the above-mentioned stabilizer is added in parts by weight, stirred for 5 minutes, and naturally cooled to normal temperature to obtain the finished product of SBS asphalt modifier C, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com