A kind of thin-layer paving material suitable for wet road and bridge deck and preparation method thereof

A technology for paving materials and road and bridge decks, which is applied in the field of pavement pavement materials, can solve the problems of not being able to cure the wet base surface, poor flexibility, poor flexibility, etc., achieve good water boiling aging resistance, and reduce the traffic accident rate , little effect of traffic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

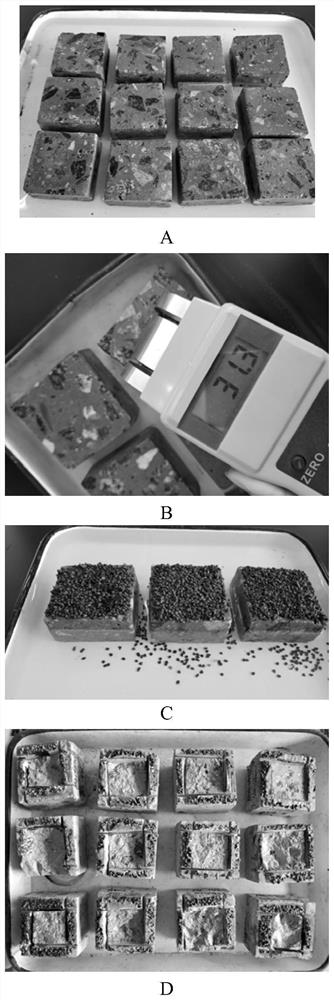

Image

Examples

Embodiment 1

[0049] The thin-layer pavement material suitable for wet road and bridge decks provided in this embodiment includes epoxy resin binder and wear-resistant aggregate, wherein the epoxy resin binder includes A component and B component with a mass ratio of 1:0.5 Components, the specific dosage of each component is as follows:

[0050] Epoxy resin binder composition (mass parts):

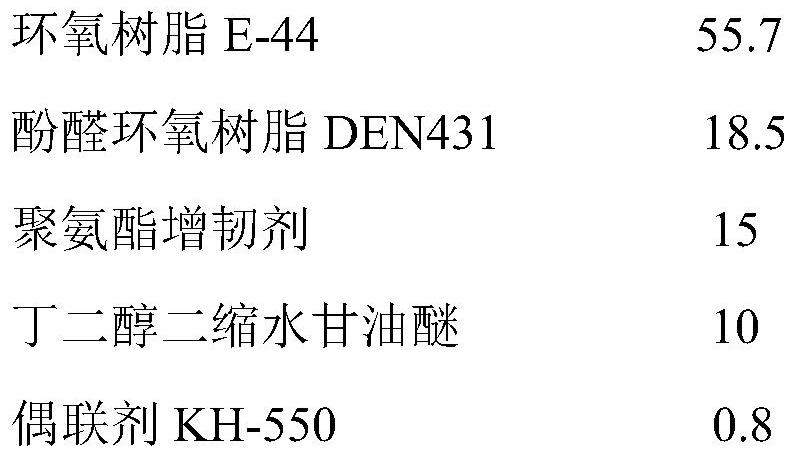

[0051] A component:

[0052]

[0053] Wherein novolak epoxy resin DEN431 includes but not limited to available from Dow Chemical.

[0054] B component:

[0055] DMP-30 5

[0056] Phenalkamide Curing Agent 65

[0057] 4,4′-Diaminodiphenylmethane 30

[0058] The wear-resistant aggregate is ceramic aggregate, the Mohs hardness is greater than 7, and the dust content is less than 1wt%. The mass percentages of particles with different particle sizes are:

[0059] Particle size 1.18mm~2.36mm 5%

[0060] Particle size 2.36mm ~ 4.75mm 95%.

[0061] The preparation method of the thin-layer paving mate...

Embodiment 2

[0066] The thin-layer pavement material suitable for wet road and bridge decks provided in this embodiment includes epoxy resin binder and wear-resistant aggregate, wherein the epoxy resin binder includes A component and B component with a mass ratio of 1:0.65 Components, the specific dosage of each component is as follows:

[0067] Epoxy resin binder composition (mass parts):

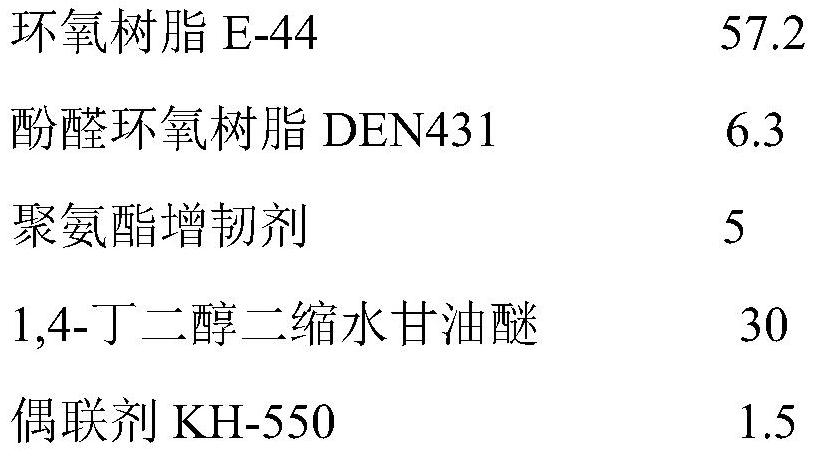

[0068] A component:

[0069]

[0070] B component:

[0071] DMP-30 8

[0072] Phenalkamide Curing Agent 70

[0073] ZY1050 modified alicyclic amine 22

[0074] The wear-resistant aggregate is corundum, the Mohs hardness is greater than 7, and the dust content is less than 1wt%. The mass percentages of particles with different particle sizes are:

[0075] Particle size 1.18mm~2.36mm 35%

[0076] Particle size 2.36mm ~ 4.75mm 65%.

[0077] The preparation method of the thin-layer paving material suitable for wet road bridge decks is as follows:

[0078] (1) According to the above dosage relati...

Embodiment 3

[0082] The thin-layer pavement material suitable for wet road and bridge decks provided in this embodiment includes epoxy resin binder and wear-resistant aggregate, wherein the epoxy resin binder includes A component and B component with a mass ratio of 1:0.75 Components, the specific dosage of each component is as follows:

[0083] Epoxy resin binder composition (mass parts):

[0084] A component:

[0085]

[0086] B component:

[0087] DMP-30 6

[0088] Phenalkamide Curing Agent 80

[0089] ZY1050 modified cycloaliphatic amine 14

[0090] The ZY1050 modified alicyclic amine curing agent includes but is not limited to those purchased from Xuzhou Zhongyan Technology Industry Co., Ltd.

[0091] The wear-resistant aggregate is basalt, the Mohs hardness is greater than 7, and the dust content is less than 1wt%. The mass percentages of particles with different particle sizes are:

[0092] Particle size 1.18mm~2.36mm 20%

[0093] Particle size 2.36mm ~ 4.75mm 80%.

[009...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com