Polycarbonate composite material with low heat release and low smoke

A technology of polycarbonate and composite materials, which is used in the field of flame-retardant materials for vehicles and low heat release, and can solve the mechanical properties of flame-retardant materials (impact resistance/scratch resistance, machinability (adverse effects of solution fluidity, There is no disclosure of the effect data of flame retardancy and mechanical properties of PC composite materials, deterioration of mechanical or physical properties, etc., to achieve the effect of low price, good light transmittance, excellent flame retardancy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] Preparation of component a polycarbonate:

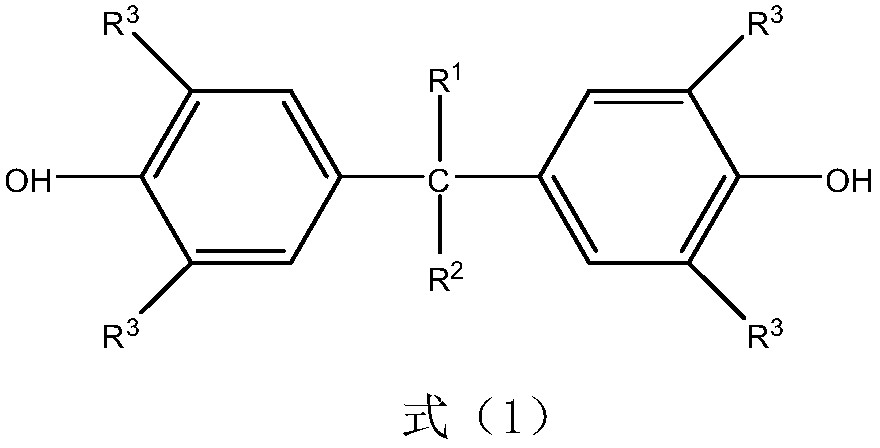

[0057] The polycarbonate of the present invention is prepared by the melt polycondensation method from the monomer of bisphenol A and formula (1) structure and diphenyl carbonate,

[0058]

[0059] where R 1 , R 2 selected from H, hydroxyl, C1-C6 alkyl, C1-C6 alkoxy, C6-C20 aryl, wherein R 1 and R 2 At least one C6-C20 aryl group; R 3 Selected from hydroxyl, C1-C6 alkyl, C1-C6 alkoxy, C6-C20 aryl, examples of the C6-C20 aryl include phenyl, naphthyl, biphenyl, the C6- C20 aryl is optionally substituted by 1-3 C1-C6 alkyl, C1-C6 alkoxy.

[0060] The melt polycondensation method is well known in the art, such as the methods described in patents CN1382172A and CN1090296A. The specific method is as follows: 1) In the first-stage transesterification step, the aromatic bisphenol monomer and diphenyl carbonate are added into the transesterification reactor according to the molar ratio of 1:1.05-1.1 and melted, then a cataly...

Embodiment 1-12

[0079] Examples 1-12 The polycarbonate composite materials prepared according to the above-mentioned general manufacturing method are described, and the raw material composition and mass percentage of these composite materials are shown in Table 3:

[0080] The raw material composition component and mass percentage of table 3 embodiment 1-12

[0081]

[0082] Continued Table 3

[0083]

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com