Functional ink and printing method thereof

A functional, ink technology, applied in ink, dyeing, textile and papermaking, etc., can solve the problems of waste of treatment agent, environmental protection, inability to achieve printing effect, and increase of treatment procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of functional ink, by weight percentage, it is made of following composition: glycerol: 25%, carboxymethyl cellulose: 5%, S-465: 0.5%, triethanolamine: 1.2%, ammonium sulfate: 4.5%, sodium tripolyphosphate: 0.7%, potassium sorbate: 0.5%, penetrant JFC: 6%, deionized water: the rest; mix and stir each component according to the weight percentage to obtain the functional ink.

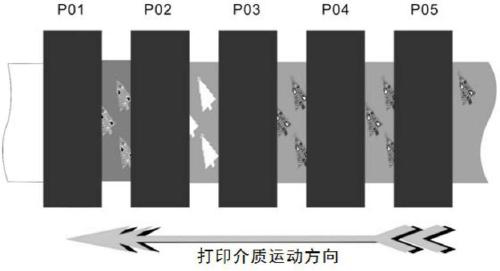

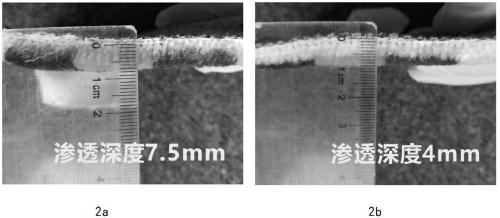

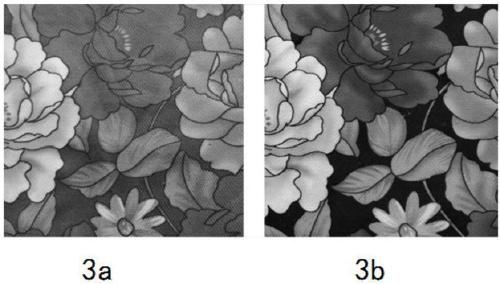

[0042] The functional ink prepared in this embodiment is matched with the acid dye inkjet ink (for example, the inkjet printing acid dye ink in ZL2010102562359 can be utilized) to be used to print the mirror image grayscale image of the desired pattern on the nylon carpet, The specific printing process includes: using the functional ink prepared in this example to print on the nylon carpet first, and then use the acid dye inkjet ink to print, and then dry, steam (25 minutes at 100° C.), Wash and then dry. At the same time, the same comparison was made with the printed matter using only aci...

Embodiment 2

[0044] A functional ink, which is made of the following components by weight percentage: 1,2-propanediol: 25%, polyvinylpyrrolidone K-40 (PVP-K40): 1%, S-465: 1%, Ammonium sulfate: 0.5%, sodium tripolyphosphate: 2.2%, dodecyldimethylbenzylamine chloride: 7.5%, isothiazolinone: 0.03%, deionized water: the rest; The functional ink is obtained by mixing and stirring the said weight percentage evenly.

[0045] The functional ink prepared in this embodiment is matched with the water-based pigment inkjet ink (for example, the water-based pigment digital printing ink in ZL2006100265953) for printing on cotton fabrics, and its specific printing process includes: using this embodiment The functional ink prepared in above was pre-printed on cotton fabric, then printed with water-based pigment inkjet ink, and dried and baked (at 160°C for 3 minutes) to obtain the finished product. At the same time, the same comparison was made with the printed matter using only water-based pigment inkje...

Embodiment 3

[0050] A functional ink, which is made of the following components by weight percentage: diethylene glycol: 21%, polyethylene glycol 400: 5%, PVP-K40: 4.5%, S-465: 0.5 %, sodium dodecylsulfonate: 0.45%, triethanolamine: 1%, sodium carbonate: 1.5%, EDTA-disodium: 0.5%, penetrant JFC: 0.5%, deionized water: the balance; According to the weight percentage, mix and stir evenly to obtain the functional ink of this embodiment.

[0051] The functional ink prepared in this embodiment is matched with the reactive dye inkjet ink (for example, the reactive dye ink in ZL2011100060210) for printing on the rayon filament fabric, and its specific printing process includes: using this embodiment The functional ink prepared in the example was pre-printed and dried on cotton fabric, then printed with reactive dye ink, dried, steamed (15 minutes at 100°C), washed in cold water, washed in hot water, soaped Wash, wash and dry to get the finished product. Simultaneously, compare with the digital ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com