Multifunctional microwave absorption coating with self-cleaning and anti-icing function and preparation method thereof

A multi-functional coating and microwave absorption technology, which is applied to radiation-absorbing coatings, coatings, antifouling/underwater coatings, etc., can solve the problems of complex preparation methods and unstable performance of composite coatings, and meet the requirements of curing conditions The effect of easy control, good stability, and excellent superhydrophobic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for preparing a self-cleaning, anti-icing and microwave-absorbing multifunctional coating, comprising the steps of:

[0045] The first step, preparation of low surface energy nanoparticle oily dispersion

[0046] a. Weigh 5g of NaOH and dissolve it in 92.5mL of deionized water to make a uniform solution for later use. Weigh 3.5g of ferrous chloride tetrahydrate (FeCl 2 4H 2 O) and 6.5 g ferric chloride hexahydrate (FeCl 3 ·6H 2 O), dissolved in deionized water, ultrasonically dispersed into a uniform solution and then transferred to the flask, when the temperature reached 65 ° C, the NaOH solution was added dropwise at a rate of 1 drop / second, and the reaction was carried out for 1.5 hours after the drop was completed. After the reaction was completed, it was cooled to room temperature, washed with deionized water ultrasonically for several times, and finally the magnetic particles were ultrasonically dispersed in water / ethanol solution (V 水 / V 乙醇 =1:4), ...

Embodiment 2

[0058] In the first step in the example 1, 3.5g ferrous chloride tetrahydrate (FeCl2 4H2O) is changed into 4.0g ferrous chloride tetrahydrate (FeCl2 4H2O). 3g of urea and 5g of cetyltrimethylammonium bromide were changed to 2g of urea and 4g of tetradecyltrimethylammonium bromide, and 35ml of n-octyltrimethoxysiloxane was changed to 45ml of n-octyltrimethoxy silicone.

[0059] All the other steps are the same as Example 1.

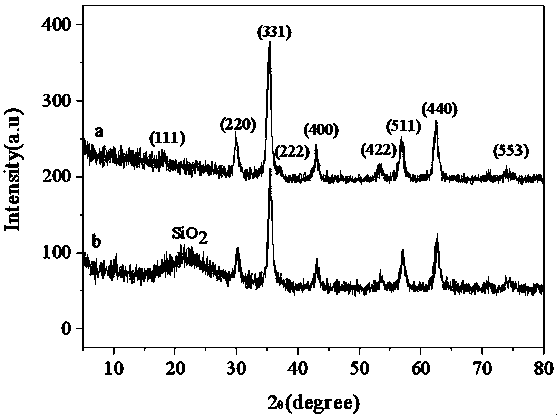

[0060] From image 3 It can be seen that the size of the core-shell structure Fe3O4 / H-SiO2 / CTAB nanoparticles decreases.

Embodiment 3

[0062] With the preparation of Fe3O4 / rGO / PANI magnetic particle / resin composite coating in the second step in the example 1, change the rGO dispersion liquid of 150ml into the rGO dispersion liquid of 200ml and the stable PANI dispersion liquid of the stick shape of 30ml into 20ml A stick-shaped stable dispersion of PANI. The content of Fe3O4 / rGO / PANI composite magnetic particles was changed from 15.0wt% to 20.0wt%. All the other steps are the same as Example 1.

[0063] From Figure 4 It can be seen that the coating with double-layer inclusion structure has excellent microwave absorption performance.

[0064] Figure 5 It is a weight loaded with 100g to pull the coating on the sandpaper, moving 10cm each time, and after 10 cycles with a total length of 100cm, the contact angle of the coating is still 168°, and the performance of the coating has not changed after cyclic friction, indicating that The coating has very good mechanical resistance. From Figure 5 It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com