Glass mold double-metal neck ring mold and preparation method thereof

A glass mold, bi-metal technology, applied in glass manufacturing equipment, glass blowing, glass forming, etc., can solve the problem of frequent gaps at the joint of nickel-based alloy and copper alloy base material, unfavorable die production cost, nickel-based alloy Alloys are expensive and other problems, to avoid the influence of human operation factors, save precious metal materials, and achieve the effect of high speed requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

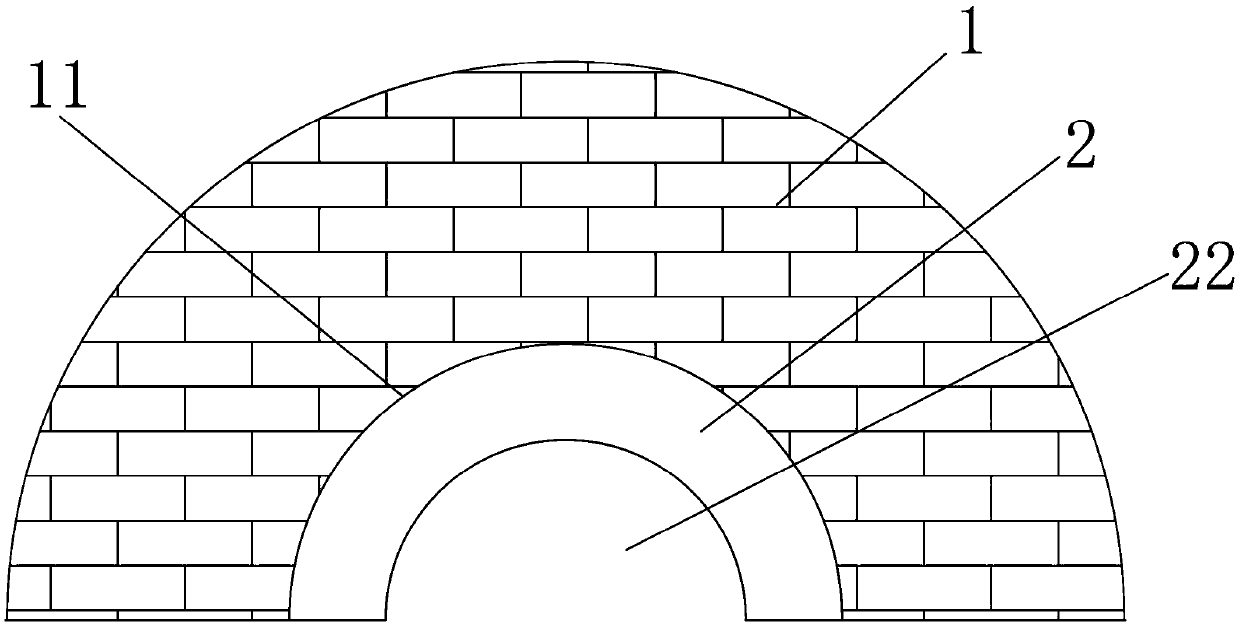

[0025] See Figure 1 to Figure 3 ,preparation figure 1 The glass mold bimetal die of shown structure comprises the following steps:

[0026] A) Pre-preparation, use acetone to clean the copper alloy substrate 1 and nickel-based alloy block 2 independently produced by the glass mold manufacturer by ultrasonic cleaning, and introduce a drying device such as an oven to dry after cleaning. Obtain a clean copper alloy substrate 1 and a clean nickel-based alloy block 2;

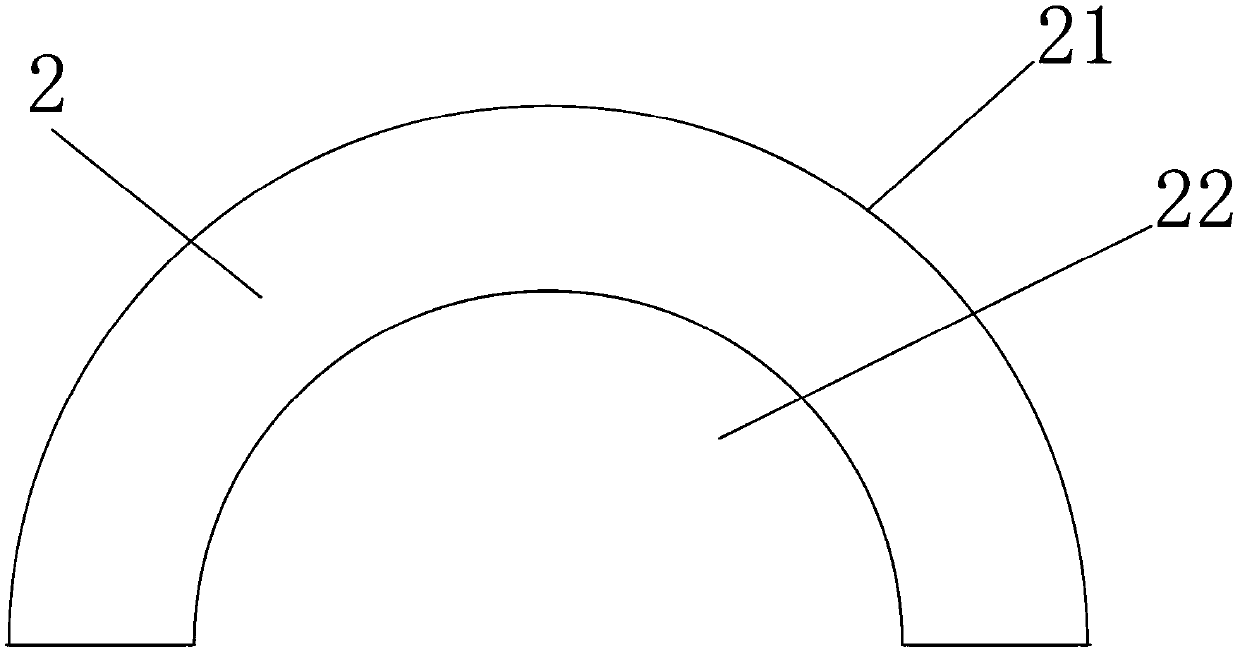

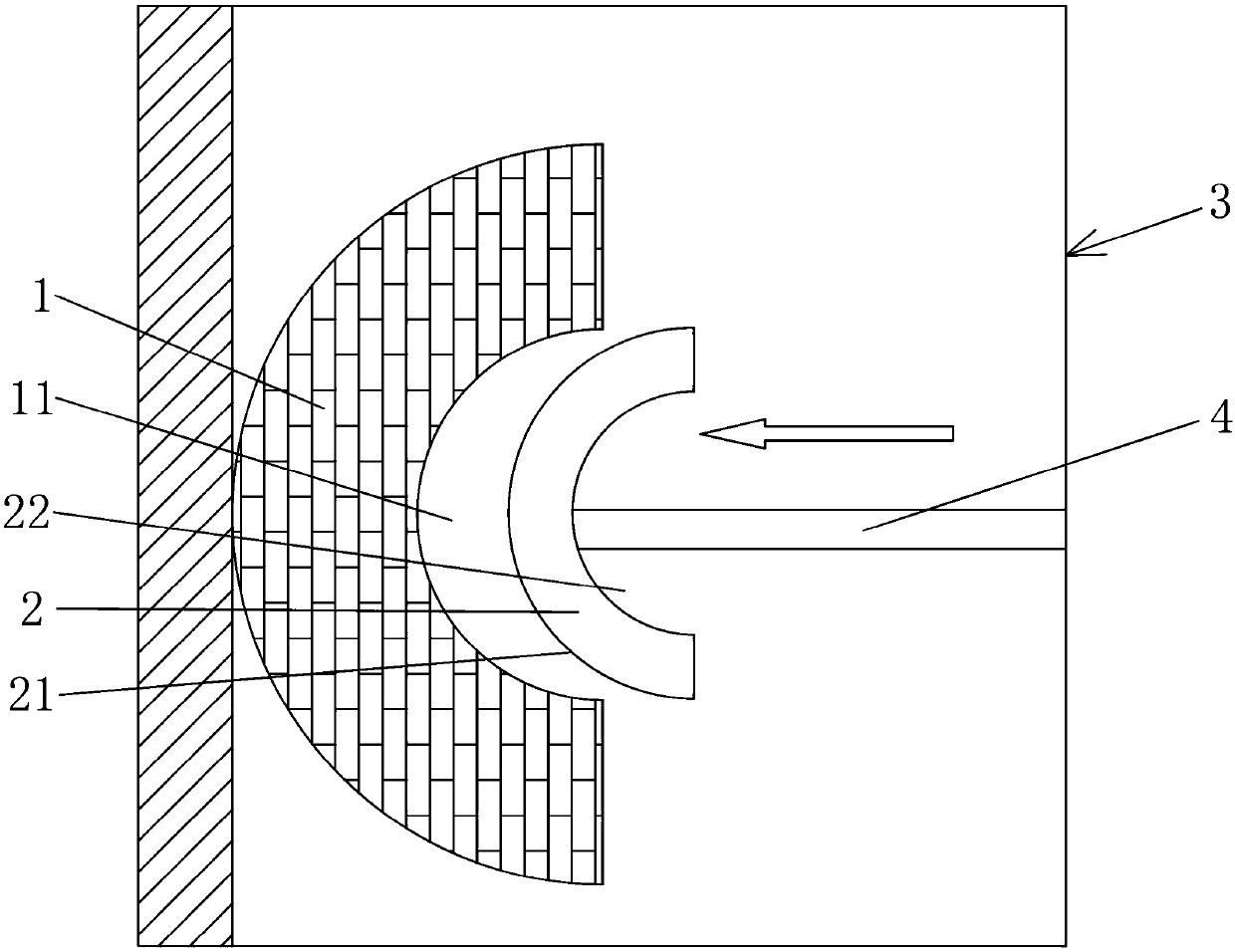

[0027] B) Diffusion welding, first introduce the clean copper alloy substrate 1 obtained in step A) and the clean nickel-based alloy block 2 into the image 3In the airtight compartment 3 shown, and the outer circular surface 21 of the nickel-based alloy block on the side of the inner cavity 11 of the nickel-based alloy block 2 facing the copper alloy substrate 1 is in good contact with the surface of the aforementioned inner cavity 11 (also called bonding), the surface roughness of the outer circular surface 21...

Embodiment 2

[0029] See Figure 1 to Figure 3 ,preparation figure 1 The glass mold bimetal die of shown structure comprises the following steps:

[0030] A) Pre-preparation, use acetone to clean the copper alloy substrate 1 and the nickel-based alloy block 2 purchased by the glass mold manufacturer as an outsourced part by ultrasonic cleaning, and introduce a drying device such as an oven after cleaning. , to obtain a clean copper alloy substrate 1 and a clean nickel-based alloy block 2;

[0031] B) Diffusion welding, first introduce the clean copper alloy substrate 1 obtained in step A) and the clean nickel-based alloy block 2 into the image 3 In the airtight compartment 3 shown, and the outer circular surface 21 of the nickel-based alloy block on the side of the inner cavity 11 of the nickel-based alloy block 2 facing the copper alloy substrate 1 is in good contact with the surface of the aforementioned inner cavity 11 (also called bonding), the surface roughness of the outer circula...

Embodiment 3

[0033] See Figure 1 to Figure 3 ,preparation figure 1 The glass mold bimetal die of shown structure comprises the following steps:

[0034] A) Pre-preparation, use acetone to clean the copper alloy substrate 1 and nickel-based alloy block 2 independently produced by the glass mold manufacturer by ultrasonic cleaning, and introduce a drying device such as an oven to dry after cleaning. Obtain a clean copper alloy substrate 1 and a clean nickel-based alloy block 2;

[0035] B) Diffusion welding, first introduce the clean copper alloy substrate 1 obtained in step A) and the clean nickel-based alloy block 2 into the image 3 In the airtight compartment 3 shown, and the outer circular surface 21 of the nickel-based alloy block on the side of the inner cavity 11 of the nickel-based alloy block 2 facing the copper alloy substrate 1 is in good contact with the surface of the aforementioned inner cavity 11 (also called bonding), the surface roughness of the outer circular surface 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com