Method and device for powder magnetron sputtering coating

A magnetron sputtering coating and powder technology, which is applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., can solve the problem of dust dispersion, failure to guarantee the uniformity of powder coating, damage to high vacuum system and Vacuum pump and other problems to achieve the effect of ensuring uniformity, ensuring effective control, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

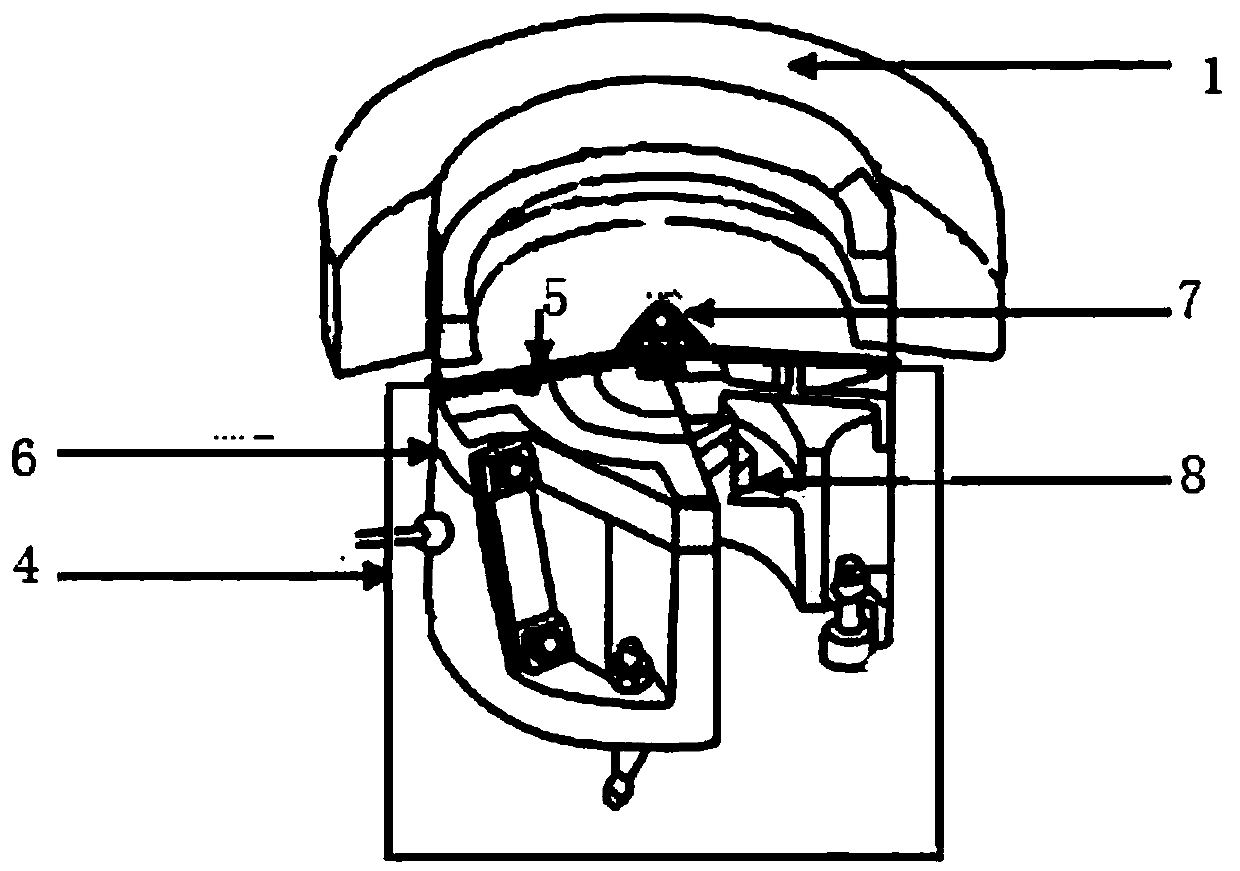

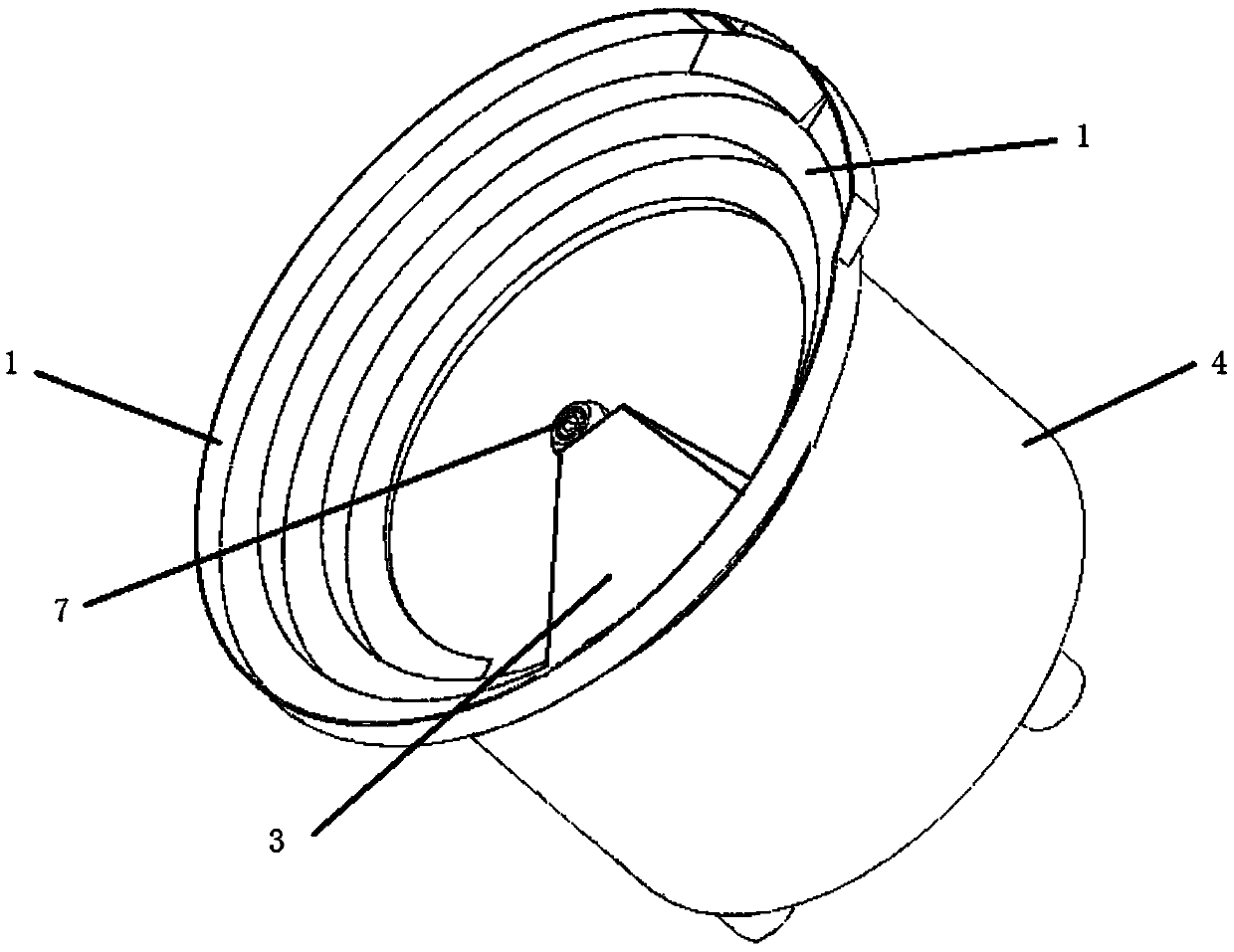

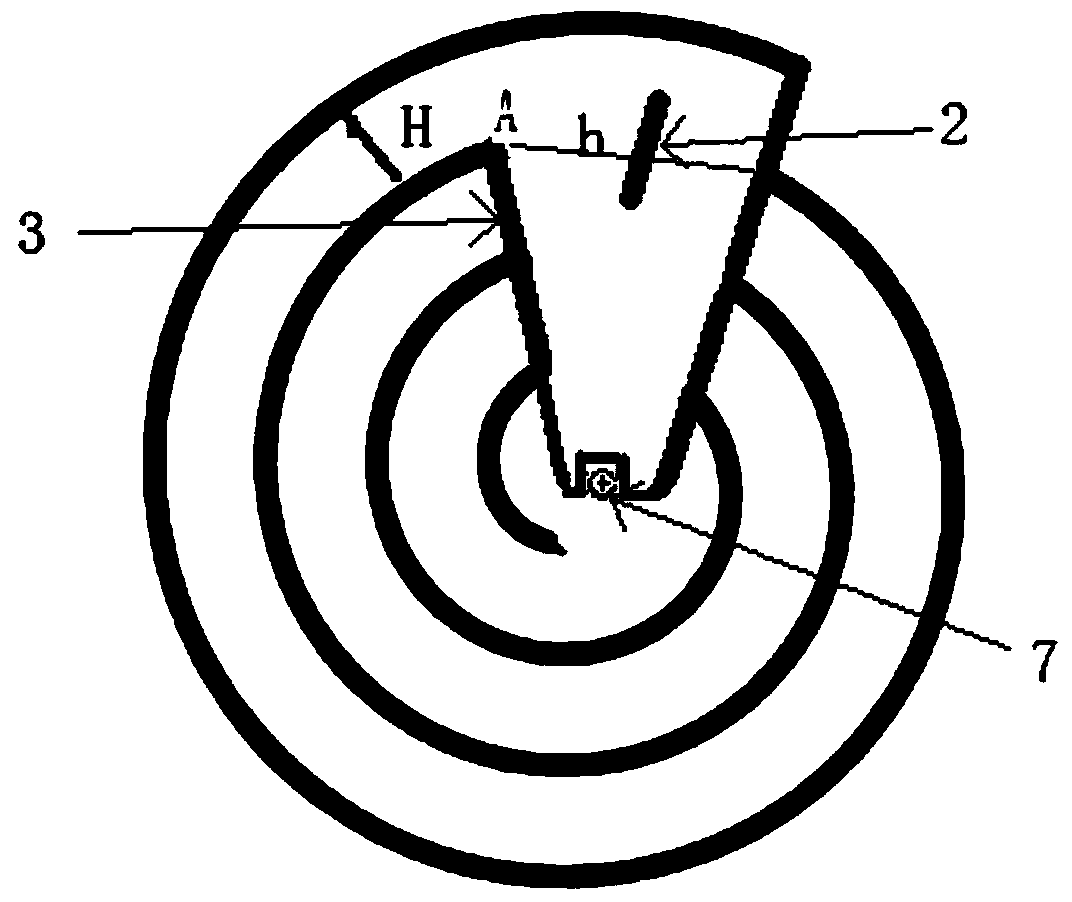

Embodiment 1

[0036] Put the vibrating plate together with the shielding tube into the magnetron sputtering studio, fix the rubber feet of the base, connect the control and power lines, align the silver target with the center of the vibrating plate at a distance of 100mm, and then pour 200g of 100μm aluminum powder Pour it into the material tray of the vibrating tray, close the furnace door and turn on the vacuum pump to evacuate, and the vacuum degree in the vacuum chamber reaches 3.0×10 -3 ~2.0×10 -4 Pa, fill the vacuum chamber with high-purity argon gas, so that the working pressure in the vacuum chamber is 3.0Pa, turn on the vibration plate switch to adjust the frequency to 100Hz, then turn on the magnetron sputtering switch to adjust the power to 80W, and the time is 240min. First turn off the magnetron sputtering equipment in order, and then turn off the vibrating plate to get good silver-coated aluminum powder.

Embodiment 2

[0038] Put the vibrating plate together with the shielding tube into the magnetron sputtering studio, fix the base rubber feet, connect the control and power lines, align the silver target with the center of the vibrating plate at a distance of 100mm, and then pour 250g of 150μm glass powder Pour it into the material tray of the vibrating tray, close the furnace door and turn on the vacuum pump to evacuate, and the vacuum degree in the vacuum chamber reaches 3.0×10 -3 ~2.0×10 -4 Pa, fill the vacuum chamber with high-purity argon gas, so that the working pressure in the vacuum chamber is 3.0Pa, turn on the vibration plate switch to adjust the frequency to 100Hz, and then turn on the magnetron sputtering switch to adjust the power to 100W for 300min. After the sputtering is completed First turn off the magnetron sputtering equipment in order, and then turn off the vibrating plate, and then a good silver-coated glass powder can be obtained.

Embodiment 3

[0040] Put the vibrating plate together with the shielding tube into the magnetron sputtering studio, fix the rubber feet of the base, connect the control and power lines, align the copper target with the center distance of 100mm of the vibrating plate, and then put 150g of 80μm graphite powder Pour it into the material tray of the vibrating tray, close the furnace door and turn on the vacuum pump to evacuate, and the vacuum degree in the vacuum chamber reaches 3.0×10 -3 ~2.0×10 -4 Pa, fill the vacuum chamber with high-purity argon gas, so that the working pressure in the vacuum chamber is 3.0Pa, turn on the vibration plate switch to adjust the frequency to 100Hz, then turn on the magnetron sputtering switch to adjust the power to 50W, and the time is 400min. First turn off the magnetron sputtering equipment in order, and then turn off the vibrating plate, and then get good copper-clad graphite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com