Dynamic vapor adsorption analysis method for formoterol fumarate amorphous form content

A technology for formoterol fumarate and adsorption analysis, which is applied in the field of dynamic vapor adsorption analysis of amorphous content of formoterol fumarate, can solve the problems of no reported amorphous content determination method, etc., and achieves quality control Effects of routine and standardization, improving drug quality and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation and characterization of ball-milled samples

[0040] Take an appropriate amount of formoterol fumarate in a ball mill, and after ball milling for 1 hour, the samples are characterized by XRPD, TGA and FTIR respectively.

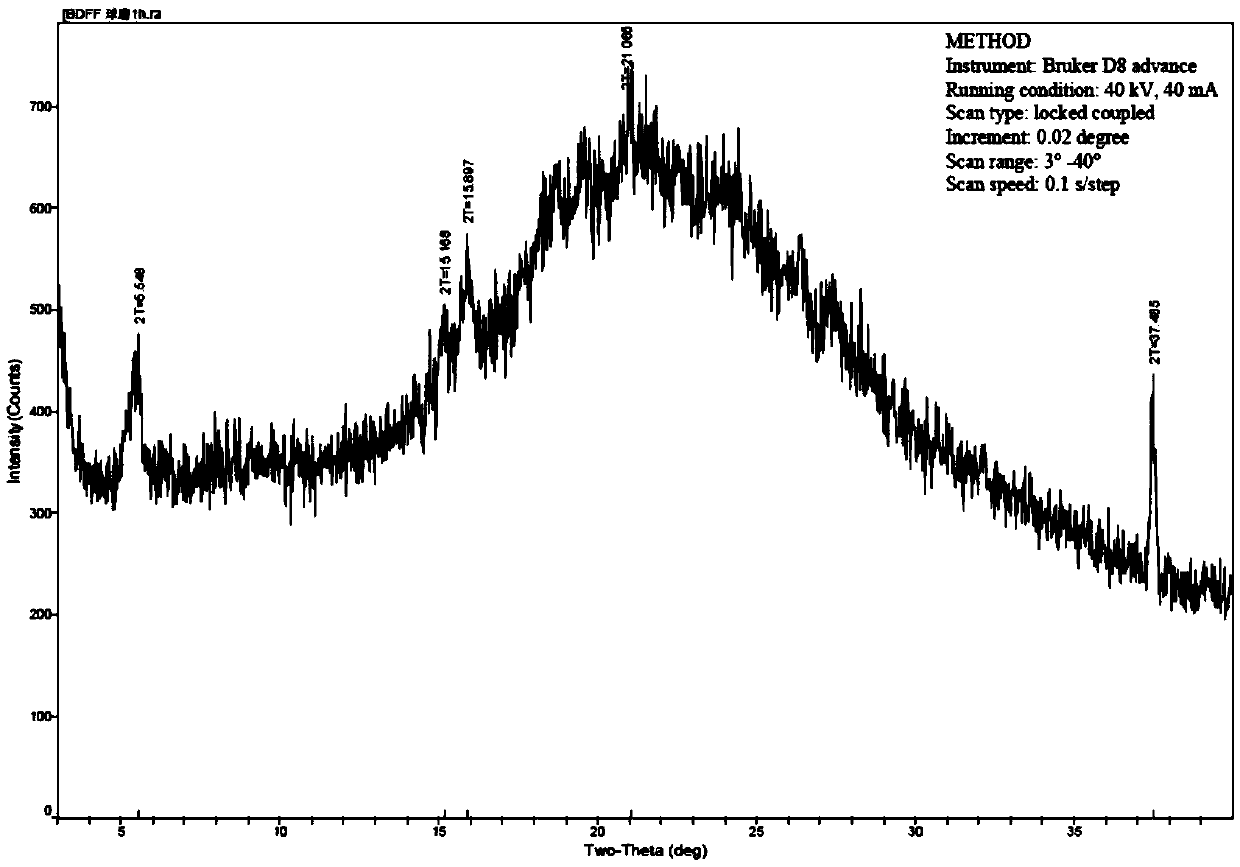

[0041] figure 1 It is an XRPD spectrum, showing that the sample is a mixture of amorphous and crystalline forms after ball milling;

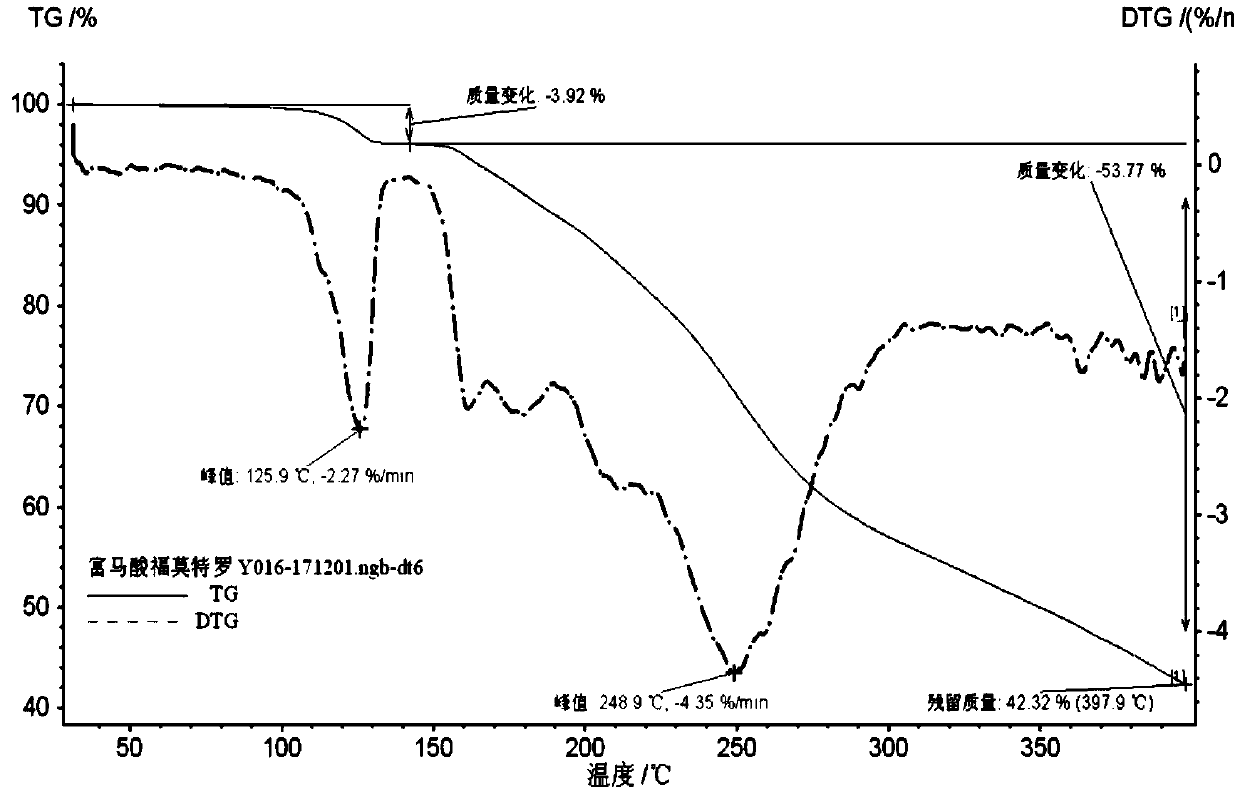

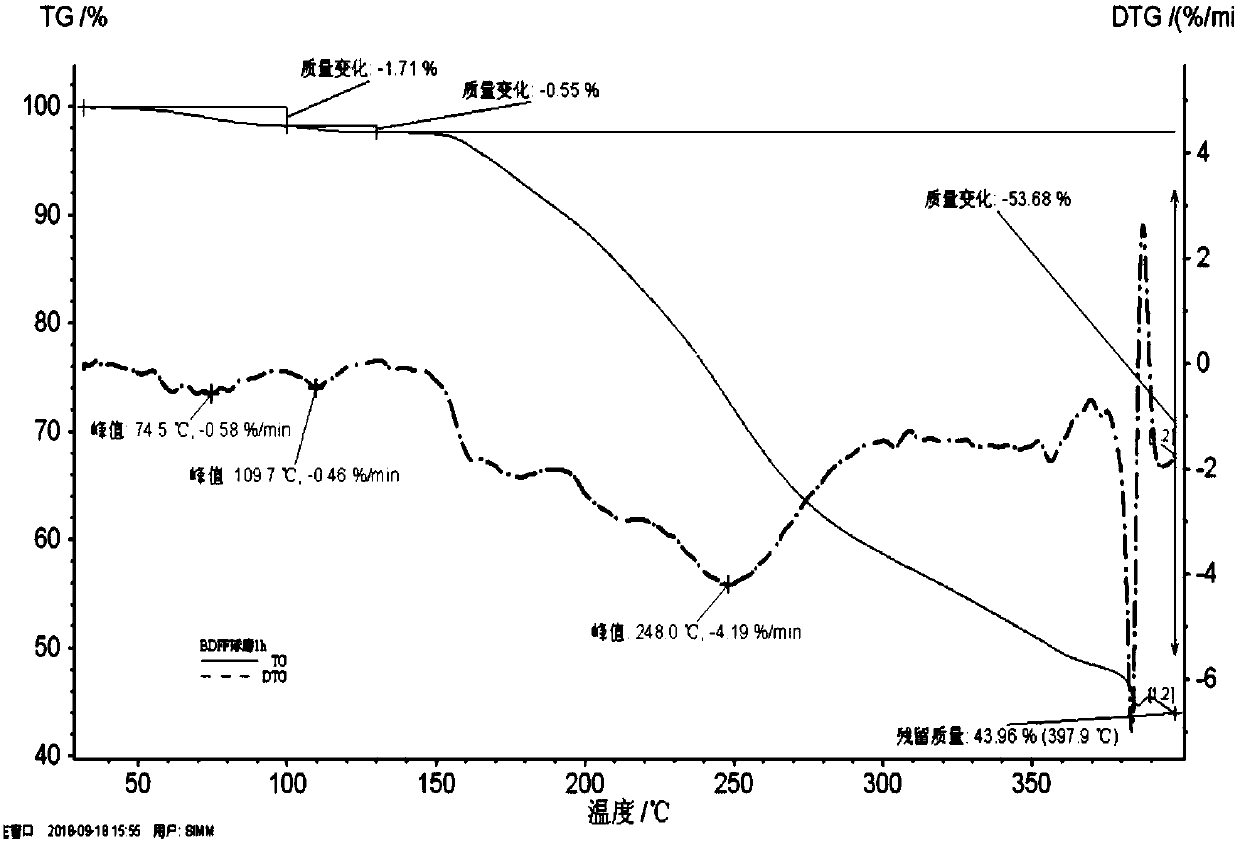

[0042] figure 2 and image 3 It is the TGA comparison spectrum before and after ball milling. The results show that the weight loss of the sample before 150 CO is 2.26% after ball milling for 1 hour, which is lower than the mass loss before ball milling (3.92%); The disappearance of hydrates.

[0043] Figure 4 and Figure 5 It is the FTIR comparison spectrum before and after ball milling. The result shows that after 1 hour of ball milling, the absorption peak of crystal water becomes weaker, and the process of ball milling is accompanied by the disappearance of crystal water.

Embodiment 2

[0045] Preparation and Characterization of Amorphous Formoterol Fumarate

[0046] Weigh 0.30±0.01g of FORC (formoterol fumarate dihydrate), dissolve it in 150mL of methanol, shake it, and ultrasonicate for 3 minutes to dissolve completely, and obtain a clear liquid. Amorphous samples were prepared by spray drying. After the sample was prepared, the sample was collected after the temperature dropped to room temperature.

[0047] The XRPD patterns of FORA (formoterol fumarate amorphous) and FORC are respectively as follows Figure 6 shown. Obvious broad diffraction peaks were observed in the XRPD pattern of FOR A, and no type characteristic peaks were found. The XRPD pattern of FORC has the characteristic absorption peak of FORC, which is consistent with the literature report.

[0048] Figure 7 It is the FTIR spectrum of the sample after spray drying, and the result shows that after spray drying, the water of crystallization disappears completely, which proves that amorpho...

Embodiment 3

[0050] Establishment and validation of a method for the detection of amorphous content of formoterol fumarate

[0051] Development of a method for the determination of the amorphous content of formoterol fumarate using a dynamic vapor sorbent (DVS).

[0052] The control steps of the dynamic vapor adsorption instrument include:

[0053] S1: Equilibrium steam for 4 hours at 25°C and 0% RH;

[0054] S2: At a rate of 10% RH, the gradient is increased from 0% RH to 90% RH, and mass balance is maintained for 15 minutes under each gradient relative humidity (the condition for maintaining mass balance is that the mass change of the sample is <0.01%);

[0055] S3: Decrease from 90% RH gradient to 0% RH at a rate of 10% RH, and maintain mass balance for 15 minutes under each gradient relative humidity (the condition for maintaining mass balance is that the sample mass change < 0.01%);

[0056] S4: The instrument automatically calculates the weight increment W.

[0057] Prepare samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com