Surface-modified nanofiber, electrolyte membrane, method for producing electrolyte membrane, membrane electrode assembly, and solid polymer fuel cell

A nanofiber and surface modification technology, applied in the field of polymer electrolyte membranes, can solve problems such as inability to exert ionic conductivity and gas permeability inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0296] Hereinafter, the present invention will be specifically described with reference to Examples and Comparative Examples, but the present invention is not limited to them at all.

Synthetic example 1

[0297] "Synthesis Example 1: Synthesis of Polybenzimidazole (PBI)"

[0298] Under nitrogen atmosphere, polyphosphoric acid (PPA) was used as the polymerization solvent, 2.27 g (10.6 mmol) of 3,3'-diaminobenzidine (DAB), 2.73 g (10.6 mmol) of 4,4'-oxobisbenzoic acid (OBBA) were weighed g (10.6 mmol), polyphosphoric acid (PPA) was added so as to be a 3 mass % solution, the temperature was gradually increased while stirring, and the mixture was stirred at 140° C. for 12 hours to synthesize polybenzimidazole. The obtained polymer solution was poured into ion-exchanged water for reprecipitation, neutralized with a sodium hydroxide solution, and washed. The polybenzimidazole was recovered by suction filtration, and after natural drying for 24 hours, it was vacuum-dried at 100°C.

[0299] Using an NMR apparatus, trade name "Burker AVANCE III500" (manufactured by Bruker BioSpin), the concentration of polybenzimidazole was measured. 1 H-NMR spectrum. Depend on 1 The H-NMR spectrum ...

Embodiment 1

[0301] "Example 1: Production of PBI Nanofiber Nonwoven"

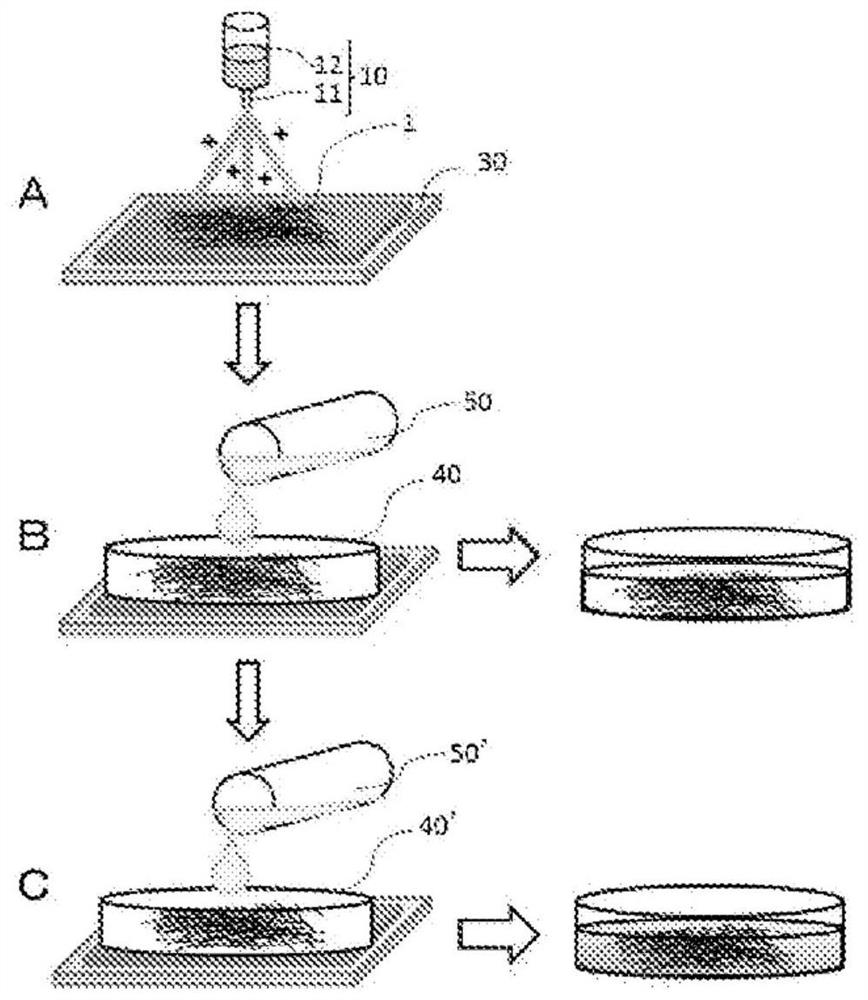

[0302] Anhydrous N,N- dimethylformamide (DMF) was added so that the polymer weight might become 8 mass %. A polymer solution was prepared by filling the vial with nitrogen and stirring overnight to dissolve. An aluminum foil was placed on the collector portion of the electrospinning device, trade name "ES-2000S" (manufactured by Fuence Corporation), a syringe filled with the polymer solution was attached to the electrospinning device, and the amount of the polymer solution released was 0.12 mL. / hour, electrospinning ( image 3 Step A shown in ). The distance between the syringe and the collector was set to 10 cm, and a voltage of 30 kV was applied to the syringe. Thus, the PBI nanofiber nonwoven fabric was laminated on the aluminum foil. Next, it was vacuum-dried at 60 degreeC for 15 hours.

[0303] A part of the nanofiber nonwoven fabric was coated with osmium and then observed with a scanning electron microscop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com