Semiconductor device

A semiconductor and conductor technology, applied in the field of impact structure, can solve the problems of defective components and large impact of components, and achieve the effect of suppressing defective components and alleviating impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024]

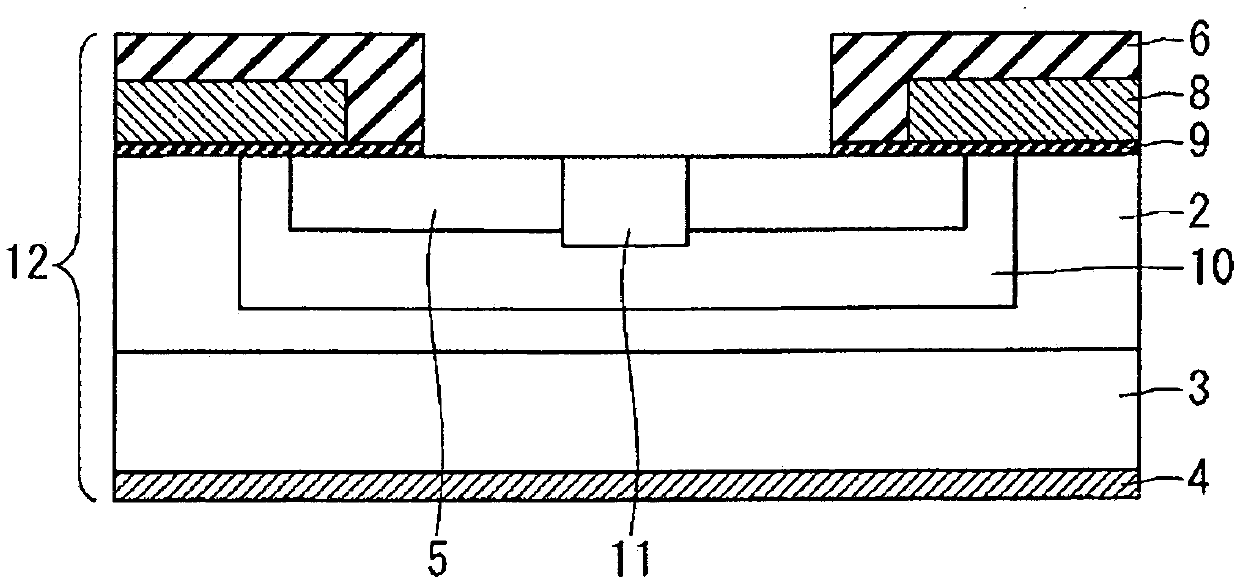

[0025] figure 1 It is a sectional view showing the structure of the power semiconductor element 12 according to Embodiment 1 of the present invention. Hereinafter, the structure of the power semiconductor element 12 will be described. As a substrate of the power semiconductor element 12, a SiC substrate 3 is used, on which an element structure is formed. When a SiC substrate is used, it is possible to fabricate a semiconductor element with low loss and high-speed operation and high-temperature operation, compared with a conventionally used Si substrate. exist figure 1 In , the power semiconductor element 12 is represented as a MOSFET (Metal-Oxide-Semiconductor Field-Effect-Transistor).

[0026] On the front side of SiC substrate 3 , drift layer 2 is formed by epitaxial growth, and on the back side, back electrode 4 electrically connected to SiC substrate 3 is formed. Base region 10 is partially formed on the surface of drift layer 2 , and source region 5 is part...

Embodiment approach 2

[0050]

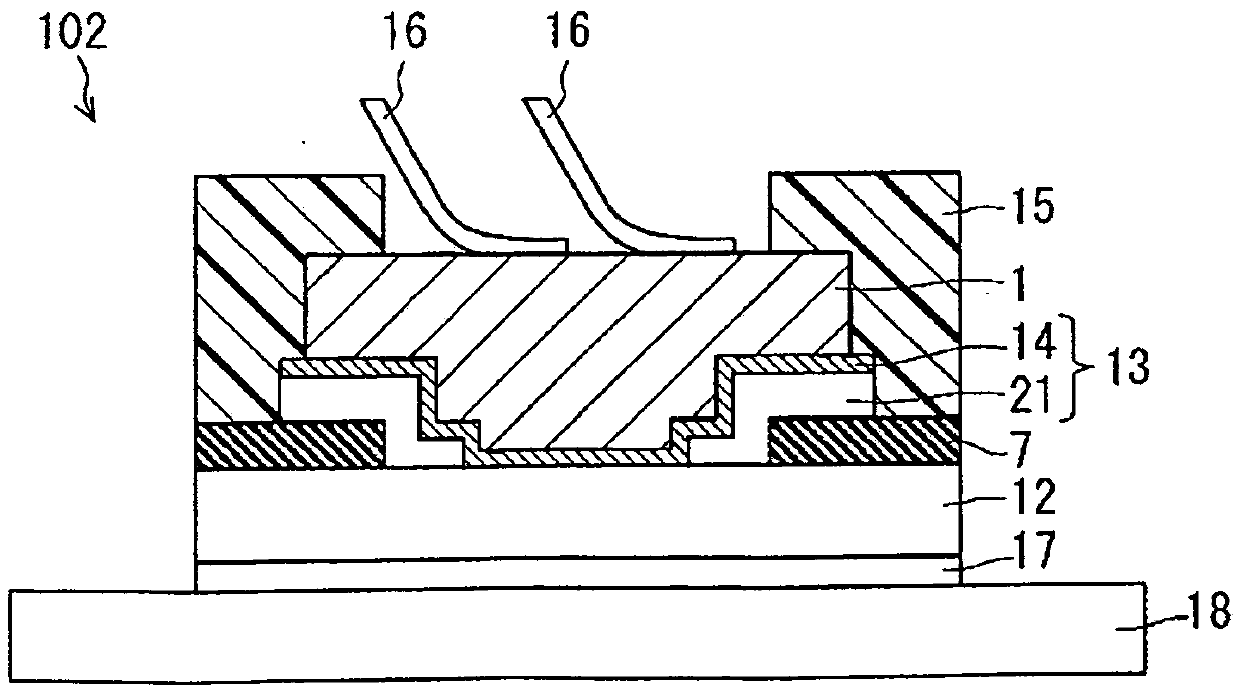

[0051] Figure 4 It is a cross-sectional view showing the structure of the semiconductor device 103 according to Embodiment 2 of the present invention. The semiconductor device 103 uses a fracture toughness value ratio including SiO 2 It is the same as the semiconductor device 102 in that the interlayer insulating film 7 and the large barrier metal layer 14 constitute a part of the stress relieving layer 13, but the barrier metal layer 14 is provided between the interlayer insulating film 7 and the non-barrier metal stress relieving layer 21. One point is different from the semiconductor device 102 . Other than that, the structure of the semiconductor device 103 is the same as that of the semiconductor device 102 .

[0052] In the semiconductor device 102 , the barrier metal layer 14 is provided between the Cu electrode 1 and the non-barrier metal stress relieving layer 21 in order to prevent Cu from the Cu electrode from diffusing in the stress relieving layer 13...

Embodiment approach 3

[0058]

[0059] Figure 5 It is a cross-sectional view showing the structure of the semiconductor device 104 according to Embodiment 3 of the present invention. In Embodiment 1 and Embodiment 2, the stress relaxation layer 13 has an opening on the opening of the interlayer insulating film 7 , and the Cu electrode 1 and the source region 5 of the power semiconductor element 12 are electrically connected through the opening of the stress relaxation layer 13 . connect. In contrast, in Embodiment 3, the stress relaxation layer 13 is formed entirely under the Cu electrode 1 from the opening of the interlayer insulating film 7 to the top of the interlayer insulating film 7 . Even with such a structure, by forming the stress relieving layer 13 with a conductor, the Cu electrode 1 is electrically connected to the source region 5 of the power semiconductor element 12 via the stress relieving layer 13 in the opening of the interlayer insulating film 7 . Examples of the material of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com