Peppermint formula particles and preparation method thereof

A technology of formula granules and mint, which is applied in the directions of pharmaceutical formulas, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve the problems of unscientific extraction process of volatile oil, reduced efficacy and strong medicinal properties, etc. Controllable quality control standards, strong production process, no toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

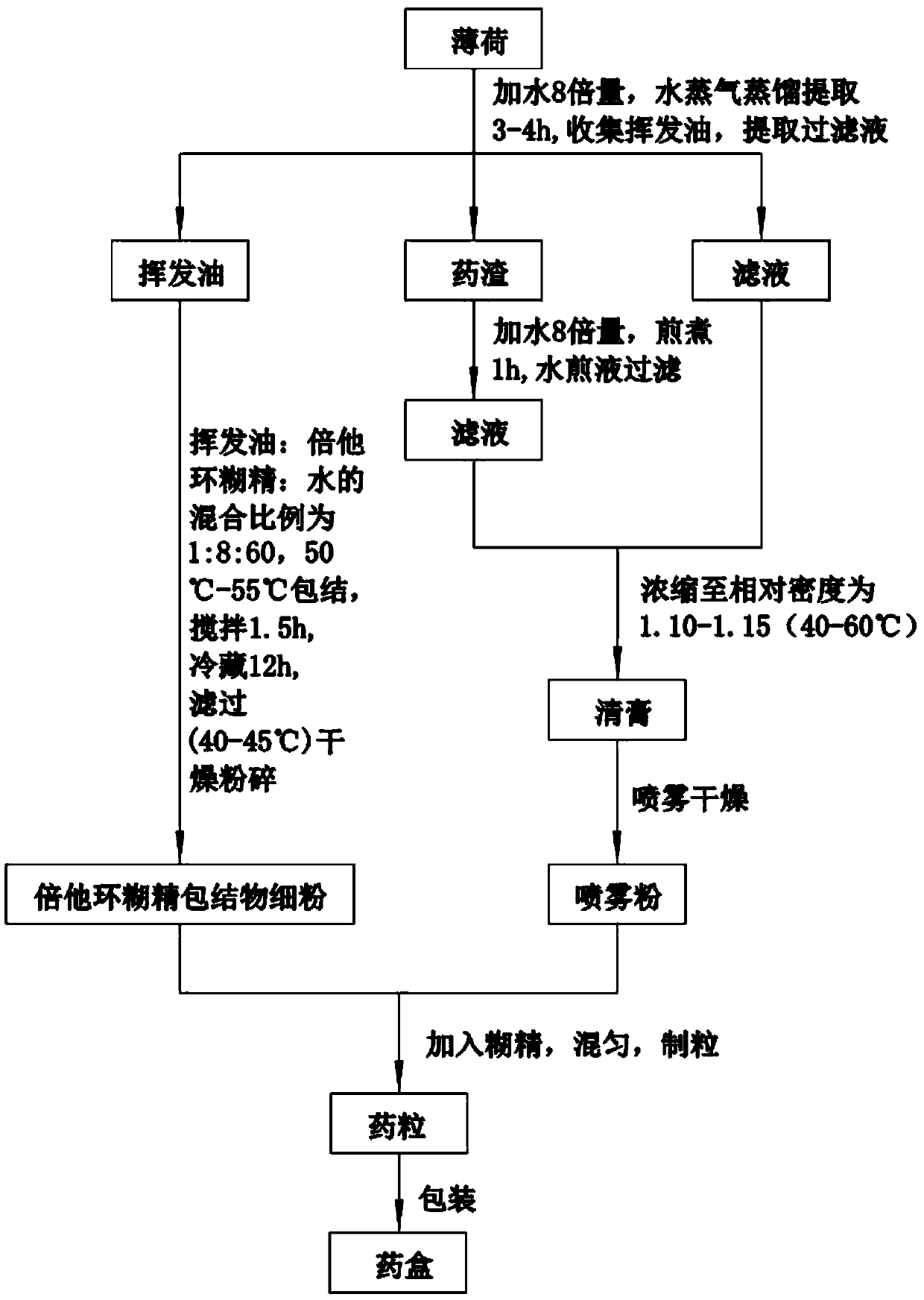

[0027] A preparation method of peppermint formula granules, comprising the steps of:

[0028] S1. Take 20 parts of mint leaves, pulverize them, and sieve to obtain mint powder;

[0029] S2. Add 160 parts of water to the mint powder in step S1, and stir to obtain a mint mixture;

[0030] S3. Distill the mint mixture in step S2 at a high temperature of 175° C. for 4 hours, collect volatile oil, filter and obtain mint dregs, and set aside;

[0031] S4. Add the volatile oil in step S3 to beta-cyclodextrin and water to mix, inclusion, stir for 1.5 hours, and then put it in the refrigerator for 12 hours, wherein the mixing ratio of water is 1:8:60, and the inclusion temperature is controlled at 50°C;

[0032] S5. Filter the refrigerated liquid in step S4 with a 40-mesh sieve, dry and pulverize at low temperature to obtain a fine powder of beta-cyclodextrin inclusion complex, and set aside;

[0033] S6. Add 160 parts of water to decoct the mint dregs in step S3 for 1 hour, then fi...

Embodiment 2

[0039] A preparation method of peppermint formula granules, comprising the steps of:

[0040] S1. Take 20 parts of mint leaves, pulverize them, and sieve to obtain mint powder;

[0041] S2. Add 180 parts of water to the mint powder in step S1, and stir to obtain a mint mixture;

[0042] S3. Distill the peppermint mixture in step S2 at a high temperature of 250° C. for 3 hours, collect volatile oil, filter and obtain mint dregs, and set aside;

[0043] S4. Add the volatile oil in step S3 to beta-cyclodextrin and water to mix, inclusion, stir for 2 hours, and then put it in the refrigerator for 12 hours, wherein the mixing ratio of water is 1:8:60, and the inclusion temperature is controlled at 50°C;

[0044] S5, filter the refrigerated liquid in step S4 with a 60-mesh sieve, dry and pulverize at low temperature to obtain a fine powder of beta-cyclodextrin inclusion complex, and set aside;

[0045] S6. Add 180 parts of water to decoct the mint dregs in step S3 for 1 hour, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com