Catalyst for isobutane dehydrogenation to isobutene

A technology for preparing isobutene and catalysts, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical elements of heterogeneous catalysts, etc. problem, to achieve the effect of good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

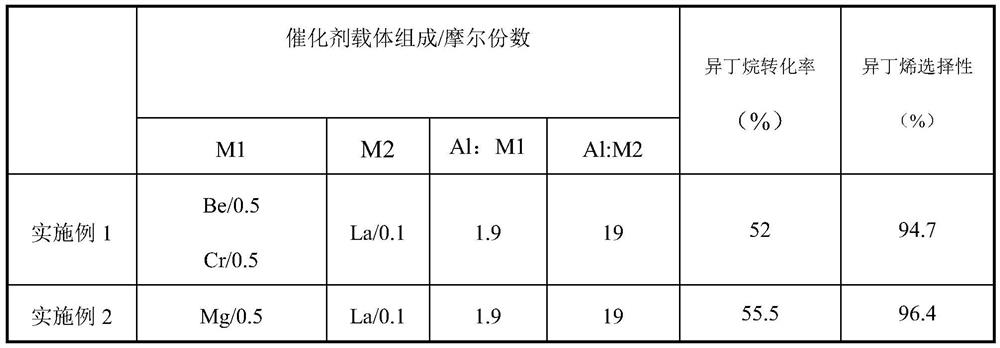

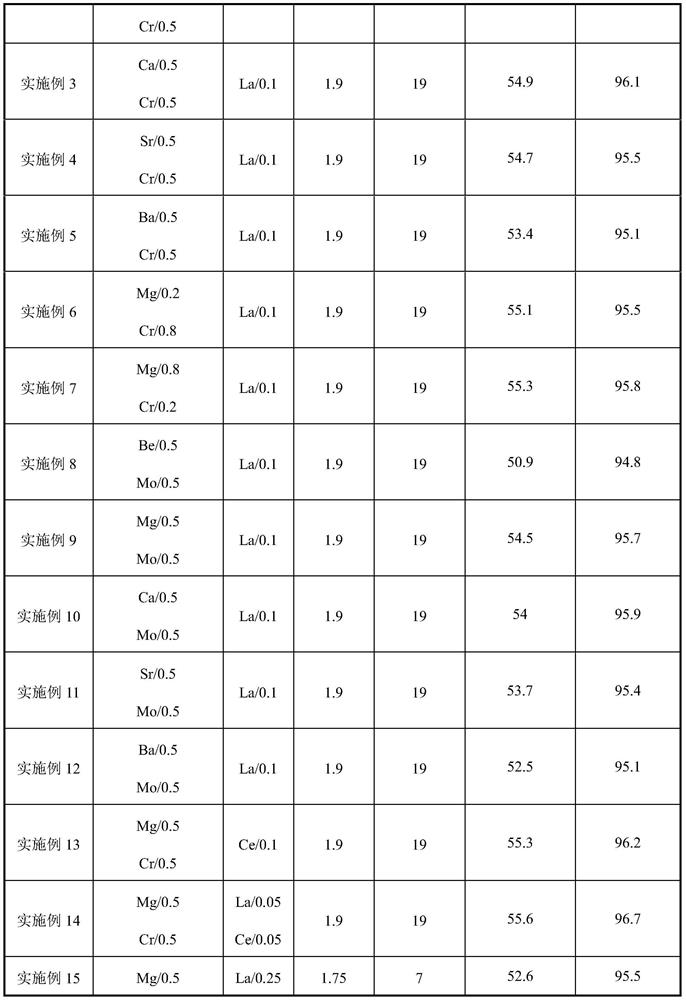

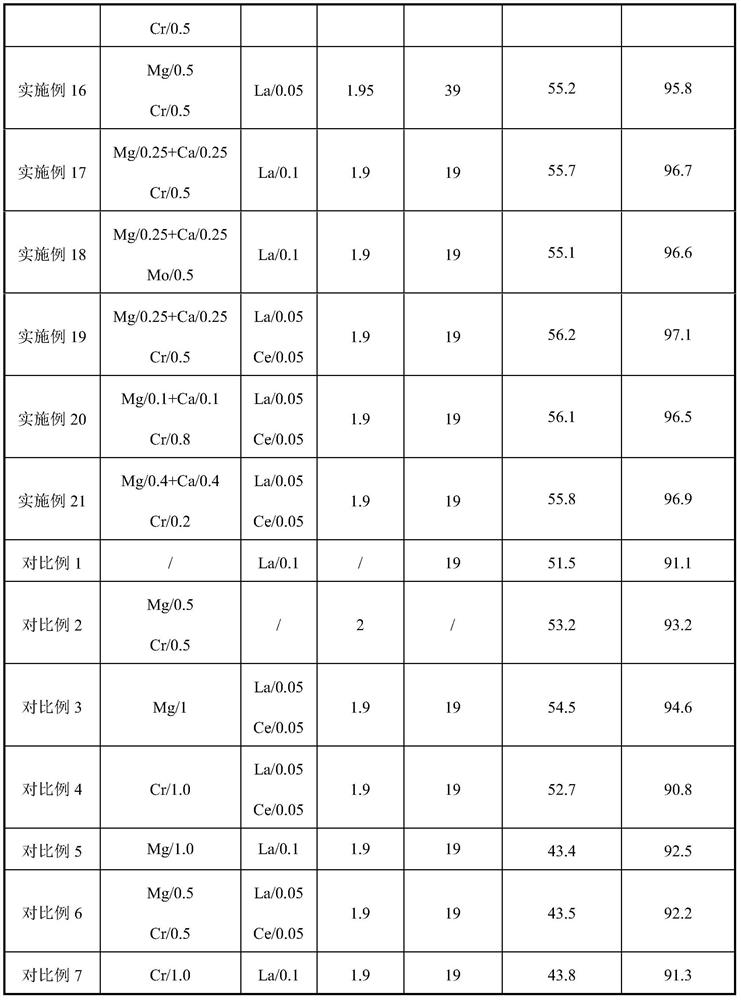

Examples

Embodiment 1

[0031]Weigh 39.97g of beryllium chloride, 133.22g of chromium chloride, 24.52g of lanthanum chloride and 253.34g of soluble salt of aluminum chloride and dissolve them in 1L of deionized water, mix well, slowly drip ammonia water under continuous stirring, Adjust the pH value to 8.0, age the product for 2 hours, filter and wash with 4L of water to obtain a filter cake, dry the filter cake at 90°C for 16 hours, and roast it in a muffle furnace at 600°C for 20 hours to obtain Be 0.5 Cr 0.5 La 0.1 al 1.9 o x carrier. Weigh 9.85g of the carrier and put it into a beaker, then weigh 0.295g of tin tetrachloride and dissolve it in 10mL of hydrochloric acid solution, add the above-mentioned carrier while stirring, mix well, soak at 30°C for 12 hours, and then dry at 90°C for 16 hours. Obtain catalyst precursor, denoted as I. Weigh 0.133 chloroplatinic acid and dissolve it in 10mL water, add it into I under stirring, mix evenly, soak at 30°C for 12 hours, dry at 90°C for 16 hours, ...

Embodiment 2

[0033] Weigh 128.2g of magnesium nitrate, 200.08g of chromium nitrate, 32.49g of lanthanum nitrate and 712.75g of soluble salt of aluminum nitrate, dissolve them in 1L of deionized water, mix well, and slowly drip ammonia water under continuous stirring to adjust the pH value 8.0, the product was aged for 2 hours, filtered and washed with 4L of water to obtain a filter cake, dried at 90°C for 16 hours, and then roasted in a muffle furnace at 600°C for 20 hours to obtain Mg 0.5 Cr 0.5 La 0.1 al 1.9 o x carrier. Weigh 9.85g of the carrier and put it into a beaker, then weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add the above-mentioned carrier under stirring, mix well, soak at 30°C for 12 hours, and then dry at 90°C for 16 hours. Obtain catalyst precursor, denoted as I. Weigh 0.133 chloroplatinic acid and dissolve it in 10mL water, add it into I under stirring, mix evenly, soak at 30°C for 12 hours, dry at 90°C for 16 hours, and ...

Embodiment 3

[0035] Weigh 88.09g of calcium acetate, 200.08g of chromium nitrate, 31.60g of lanthanum acetate and 307.96g of basic aluminum acetate soluble salt, dissolve them in 1L of deionized water, mix well, and slowly drip ammonia water under continuous stirring to adjust the pH The value is 8.0, the product is aged for 2 hours, filtered and washed with 4L of water to obtain a filter cake, dried at 90°C for 16 hours, and then roasted in a muffle furnace at 600°C for 20 hours to obtain Ca 0.5 Cr 0.5 La 0.1 al 1.9 o x carrier. Weigh 9.85g of the carrier and put it into a beaker, then weigh 0.190g of stannous chloride and dissolve it in 10mL of hydrochloric acid solution, add the above-mentioned carrier under stirring, mix well, soak at 30°C for 12 hours, and then dry at 90°C for 16 hours. Obtain catalyst precursor, denoted as I. Weigh 0.133 chloroplatinic acid and dissolve it in 10mL water, add it into I under stirring, mix evenly, soak at 30°C for 12 hours, dry at 90°C for 16 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com