A kind of composite carrier catalyst for propane conversion to propylene and preparation method thereof

A composite carrier and catalyst technology, used in catalyst activation/preparation, physical/chemical process catalysts, molecular sieve catalysts, etc. Good regeneration performance, good industrial application prospects, and the effect of reducing side reactions of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

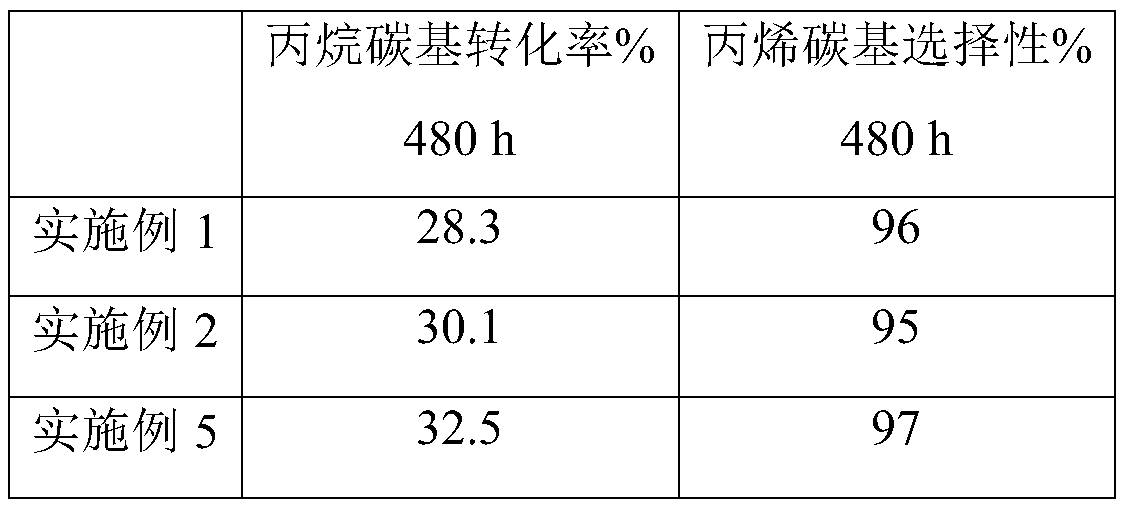

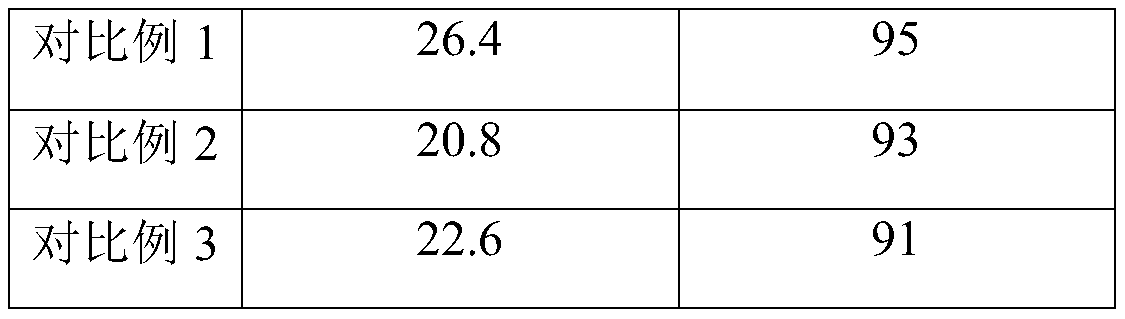

Examples

Embodiment 1

[0027] 1) Weigh a certain amount of SBA-15 molecular sieve in a three-neck flask, add a certain concentration of aluminum nitrate and zinc nitrate and stir fully at 90°C for 12-24h, wash and filter with distilled water, dry at 120°C, and finally place in a calciner Calcined at 550°C for 5h to obtain doped Al(5)-Zn(3)-SBA-15 molecular sieve, which was recorded as component A; then weighed a certain amount of β-gibbsite and calcined at 800°C 4h to obtain component B; finally, mix the above two components A and B in a certain proportion and set aside.

[0028] 2) After mixing the weighed compounds of the first, second and third components, add 1mo / L aqueous HCl solution to dissolve to form a mixed solution.

[0029] 3) The mixed solution in step 2) was added to the powder in step 1), and 5% dilute nitric acid was added to form a sol, which was stirred at 70° C. for 8 hours. The solid content in the sol was 40%.

[0030] 4) Spray-dry the sol in step 3) to obtain a fine powder, an...

Embodiment 2

[0034] 1) Weigh a certain amount of SBA-15 molecular sieve in a three-neck flask, add a certain concentration of aluminum nitrate and zinc nitrate and stir fully at 90°C for 12-24h, wash and filter with distilled water, dry at 120°C, and finally place in a calciner Calcined at 550°C for 5 hours to obtain doped Al(4)-Zn(2)-SBA-15 molecular sieve, which was recorded as component A; then weighed a certain amount of β-gibbsite and calcined at 850°C 5h to obtain component B; finally, mix the above two components A and B in a certain proportion and set aside.

[0035] 2) After mixing the weighed compounds of the first, second and third components, add 0.5mo / L aqueous HCl solution to decompose to form a mixed solution.

[0036] 3) The mixed solution of step 2) was added to the powder of step 1), and 3% dilute nitric acid was added to form a sol, which was stirred at 90° C. for 8 hours, and the solid content in the sol was 50%.

[0037] 4) Spray-dry the sol in step 3) to obtain a fin...

Embodiment 3

[0041] 1) Weigh a certain amount of SBA-15 molecular sieve in a three-neck flask, add a certain concentration of aluminum nitrate and zinc nitrate and stir fully at 90°C for 12-24h, wash and filter with distilled water, dry at 120°C, and finally place in a calciner Calcined at 550°C for 5h to obtain doped Al(10)-Zn(2)-SBA-15 molecular sieve, which was recorded as component A; then weighed a certain amount of β-gibbsite and calcined at 900°C 4h to obtain component B; finally, mix the above two components A and B in a certain proportion and set aside.

[0042] 2) After mixing the weighed compounds of the first, second and third components, add 0.3 mol / L HF aqueous solution to decompose to form a mixed solution.

[0043] 3) The mixed solution of step 2) was added to the powder of step 1), and 6% dilute nitric acid was added to form a sol, which was stirred at 60° C. for 12 hours, and the solid content in the sol was 30%.

[0044] 4) Spray-dry the sol in step 3) to obtain a fine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com