Method for preparing nickel-based methane dry reforming catalyst

A technology for dry reforming of methane and nickel-based methane, applied in molecular sieve catalysts, chemical instruments and methods, catalysts for physical/chemical processes, etc. problems, to achieve excellent hydrothermal stability, good catalyst structure retention, and the effect of inhibiting sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

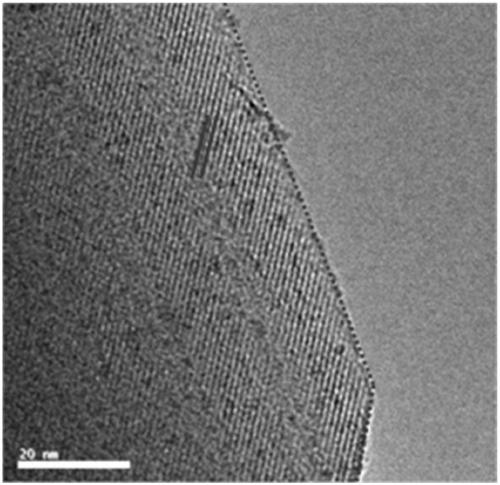

Image

Examples

Embodiment 1

[0032]Weigh 0.37g Ni(acac) 2 , 1.14g oleic acid, put into vials, and seal with polytetrafluoroethylene tape. Put the mixture into a dry box and set it at 105°C to heat and dissolve for about 2 hours. Weigh 5.88g TEOS and 0.894g APTES and put them into small test tubes. Add 115ml of deionized water and 50ml of ethanol into the three-neck flask, start stirring, add oleic acid and the mixture in the small test tube in turn with a dropper during stirring, and then stir vigorously for 5 minutes. After the stirring is completed, let stand for 2h. Subsequently, in an oil bath at 80 °C for 24 h. After the oil bath was completed, it was filtered with suction and washed twice with deionized water. Put the suction-filtered product together with the filter paper into a drying oven at 105°C for 5 to 6 hours. After drying, remove the filter paper, grind the sample to powder, and then use a muffle furnace to roast at 800 ° C for 2 hours, using a program to increase the temperature by 2 ...

Embodiment 2

[0036] Weigh 0.185g Ni(acac) 2 , 1.14g oleic acid, put into vials, and seal with polytetrafluoroethylene tape. Put the mixture into a dry box and set it at 105°C to heat and dissolve for about 2 hours. Weigh 5.88g TEOS and 0.894g APTES and put them into small test tubes. Add 115ml of deionized water and 50ml of ethanol into the three-neck flask, start stirring, add oleic acid and the mixture in the small test tube in turn with a dropper during stirring, and then stir vigorously for 5 minutes. After the stirring is completed, let stand for 2h. Subsequently, in an oil bath at 80 °C for 24 h. After the oil bath was completed, it was filtered with suction and washed twice with deionized water. Put the suction-filtered product together with the filter paper into a drying oven at 105°C for 5 to 6 hours. After drying, remove the filter paper, grind the sample to powder, and then use a muffle furnace to roast at 800 ° C for 2 hours, using a program to increase the temperature by ...

Embodiment 3

[0040] Weigh 0.37g Ni(acac) 2 , 1.14g oleic acid, put into vials, and seal with polytetrafluoroethylene tape. Put the mixture into a dry box and set it at 105°C to heat and dissolve for about 2 hours. Weigh 5.88g TEOS and 0.894g APTES and put them into small test tubes. Add 115ml of deionized water and 50ml of ethanol into the three-neck flask, start stirring, add oleic acid and the mixture in the small test tube in turn with a dropper during stirring, and then stir vigorously for 5 minutes. After the stirring is completed, let stand for 2h. Subsequently, in an oil bath at 80 °C for 24 h. After the oil bath was completed, it was filtered with suction and washed twice with deionized water. Put the suction-filtered product together with the filter paper into a drying oven at 105°C for 5 to 6 hours. After drying, remove the filter paper, grind the sample to powder, and then use a muffle furnace to roast at 800 ° C for 2 hours, using a program to increase the temperature by 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com