Preparation method of controllable double-aqueous-phase droplets based on micro-fluidic technology

A microfluidic technology, a two-phase technology, applied in the field of material chemistry and microfluidic technology, can solve problems such as widespread application obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

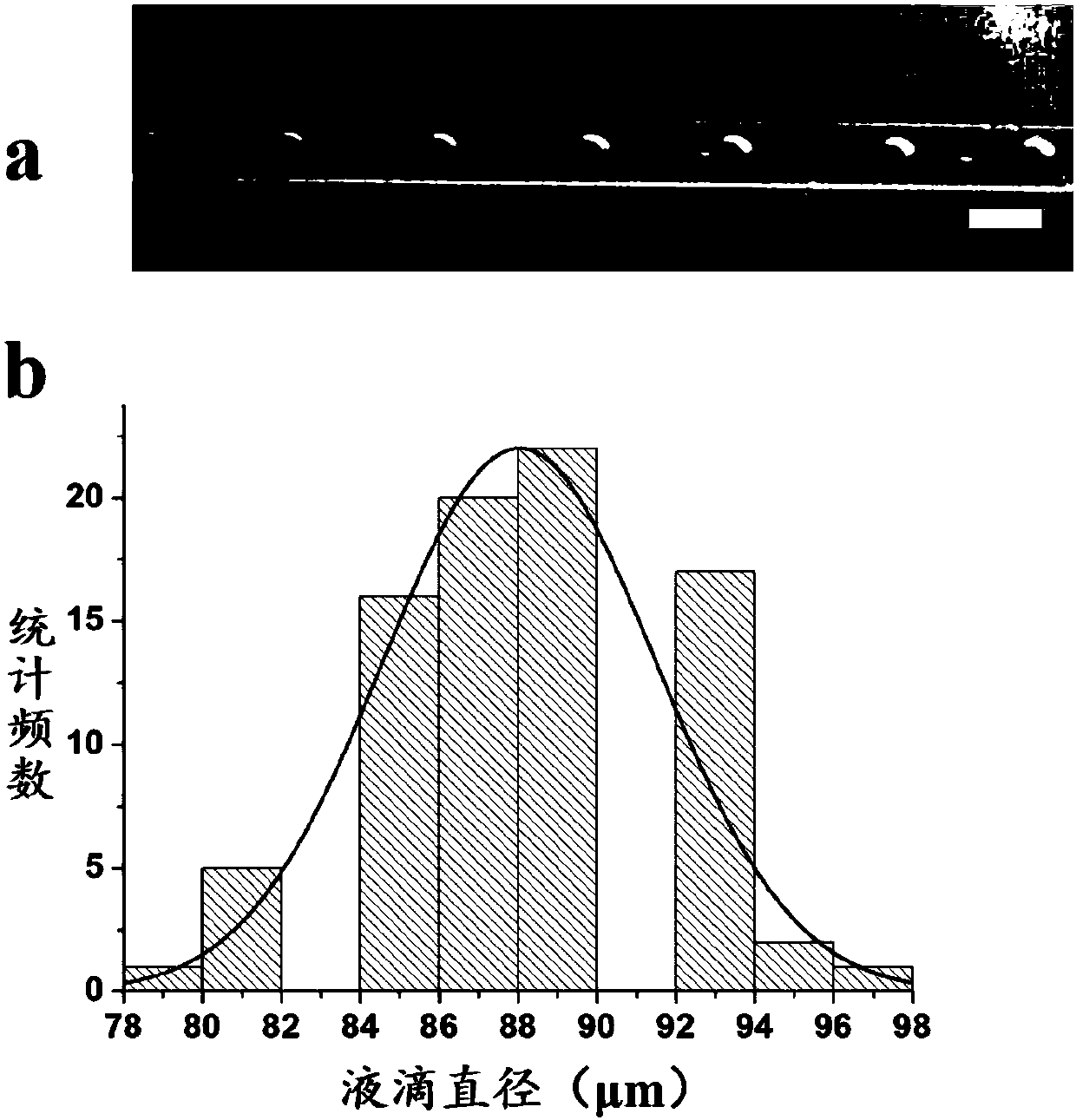

Embodiment 1

[0023] A method for preparing controllable two-phase liquid droplets based on microfluidic technology, characterized in that: comprising the following steps:

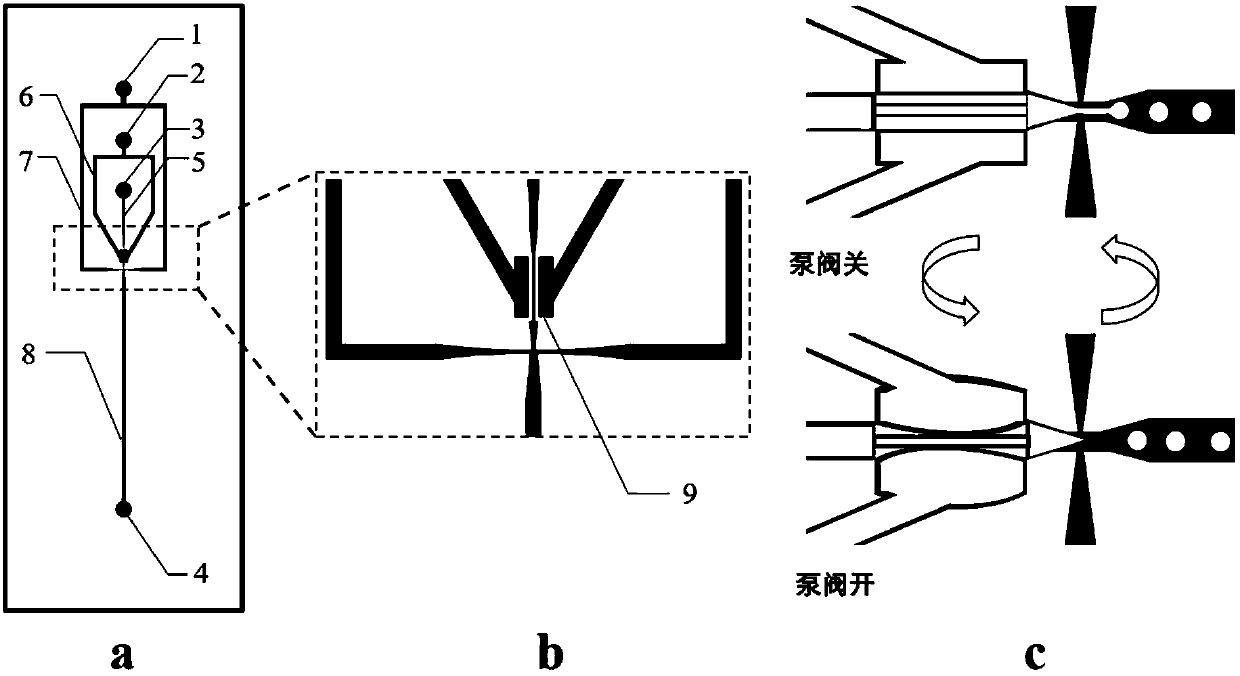

[0024] (1) Integration of the pump valve system: using conventional soft lithography method to prepare a PDMS chip, based on a traditional "cross" flow microfluidic droplet chip, integrated on both sides of the dispersed phase channel upstream of the "cross" intersection Pneumatic pump valve; the chip as figure 1 As shown, it is mainly composed of continuous phase inlet 1, gas inlet 2, dispersed phase inlet 3, droplet outlet 4, dispersed phase channel 5, gas channel 6, continuous phase channel 7, main channel 8 and pump valve 9;

[0025] The continuous phase inlet 1 and the dispersed phase inlet 3 are respectively connected to the main channel 8 through the continuous phase channel 7 and the dispersed phase channel 5, and the dispersed phase channel and the continuous phase channel converge to the main channel to form a...

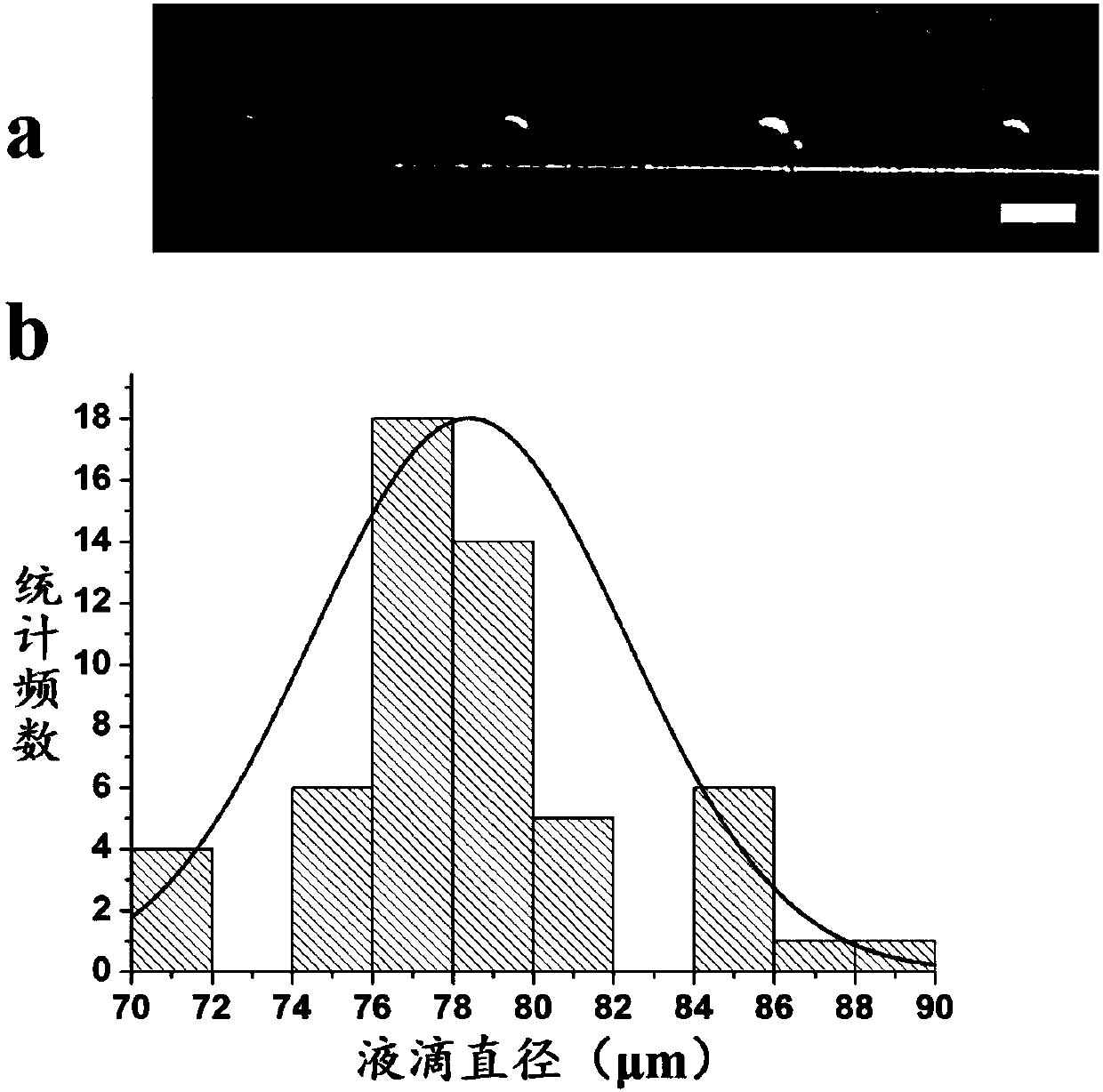

Embodiment 2

[0031] (1) Integration of the pump valve system: using conventional soft lithography method to prepare a PDMS chip, based on a traditional "cross" flow microfluidic droplet chip, integrated on both sides of the dispersed phase channel upstream of the "cross" intersection Pneumatic pump valve; the chip as figure 1 As shown, it is mainly composed of continuous phase inlet 1, gas inlet 2, dispersed phase inlet 3, droplet outlet 4, dispersed phase channel 5, gas channel 6, continuous phase channel 7, main channel 8 and pump valve 9;

[0032] The continuous phase inlet 1 and the dispersed phase inlet 3 are respectively connected to the main channel 8 through the continuous phase channel 7 and the dispersed phase channel 5, and the dispersed phase channel and the continuous phase channel converge to the main channel to form a "cross" intersection; The channel 6 reaches the pneumatic pump valve 9, and the gas in it drives the elastic deformation of the side wall of the pump valve;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com