Preparation method of high-purity selenium sulfide

A high-purity technology of selenium disulfide, which is applied in the field of preparation of high-purity selenium disulfide, can solve the problems of high equipment and personnel requirements, increased pressure of quartz tubes, and easy explosion, so as to facilitate subsequent washing and ensure Product purity, sedimentation and fluffy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

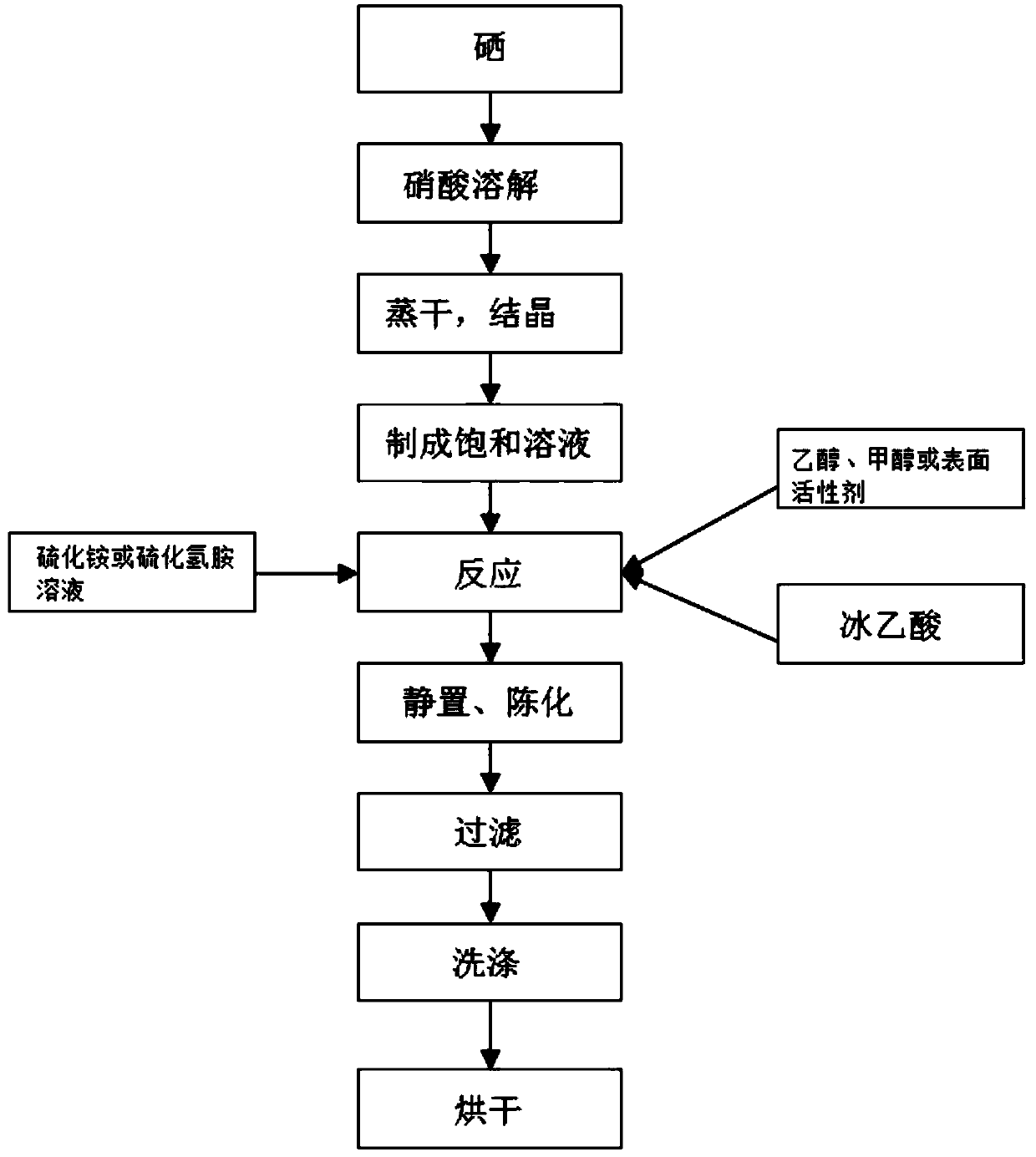

Method used

Image

Examples

example 1

[0037] A. Dissolve raw material selenium in nitric acid solution.

[0038] Weigh 1000g of 99.99% selenium raw material and dissolve it completely in 4L premium grade nitric acid (HNO 3 ) In the solution, the chemical reaction formula is Se+4HNO 3 =H 2 SeO 3 +4NO 2 ↑+H 2 O.

[0039] B. Crystallize the reacted selenite in the above solution.

[0040] The solution is completely evaporated to dryness by evaporation, and white selenous acid crystals (H 2 SeO 3 ).

[0041] C. Dissolve selenite crystals in water and filter to make a saturated solution.

[0042] The prepared selenite (H 2 SeO 3 ) The crystals are dissolved in ultrapure water and filtered to make a saturated solution. Ultrapure water (Ultrapure water), also known as UP water, refers to water with a resistivity of 18MΩ*cm (25°C). Apart from water molecules, this kind of water has almost no impurities, and no bacteria, viruses, chlorinated dioxins and other organic substances. Of course, there are no mineral trace elements requi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com