Novel method for preparing pitch-based mesocarbon microbeads

A technology of mesocarbon microspheres and a new method, which is applied in the preparation/purification of carbon, coking carbon-containing materials, petroleum industry, etc., can solve the problems of difficult separation, poor uniform particle size distribution of microspheres, etc. control, good uniformity and easy subsequent separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

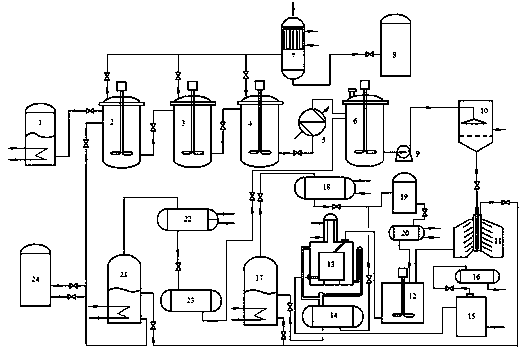

[0017] see figure 1 , this embodiment consists of the following steps:

[0018] Step A. Select the medium-temperature coal tar pitch heated at 230°C and thermally polymerize it at about 230°C

[0019] The mesophase pitch is mixed according to the ratio of 1:1-1.2, sent to the pre-mixing tank, heated to 250°C-270°C under the protection of nitrogen, and kept for 4 hours. After pretreatment, the raw materials enter the pre-reaction tank, and under the protection of nitrogen, Heating to 320°C-340°C, preheating polymerization reaction for 4 hours;

[0020] Step B, preheating the polymerized asphalt into the reactor, heating to 375-385°C under the protection of nitrogen,

[0021] The reaction pressure is 0.4-1.0MPa, and thermal polymerization is carried out for 8 hours to 16 hours;

[0022] Step C, the asphalt after thermal polymerization is cooled to 150°C-170°C through the reaction product heat exchanger, and an appropriate amount of quinoline solvent is added to the reaction p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com