Multifunctional stable coated fertilizer and preparation method thereof

A stable and multi-functional technology, used in layered/coated fertilizers, organic fertilizers, ammonium nitrate fertilizers, etc., can solve the problems of unguaranteed fertilizer efficiency, unstable product quality, affecting product appearance, etc., to improve the application effect, improved appearance, good fixation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

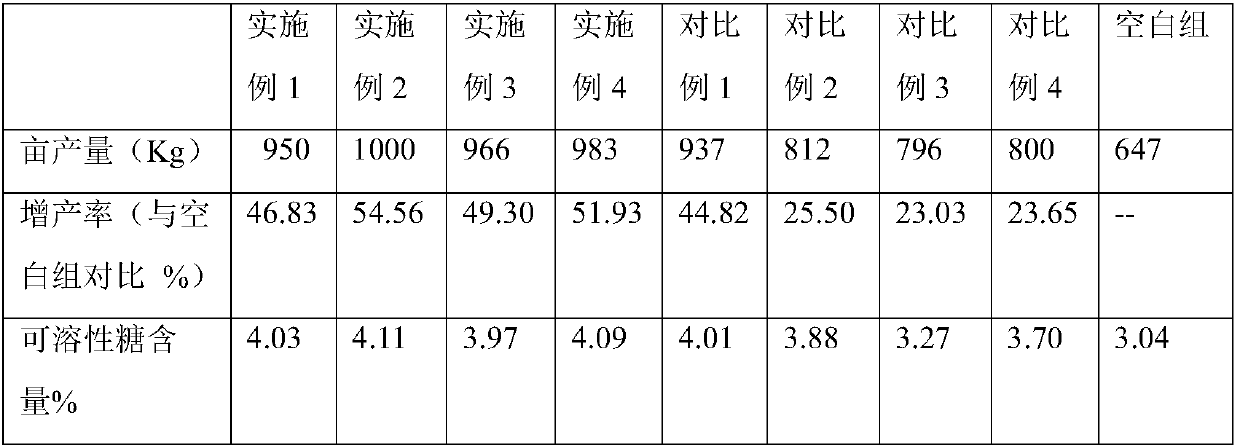

Embodiment 1

[0030] Preparation of Multifunctional and Stable Coated Fertilizer

[0031] Spray 20Kg of bonding auxiliary agent on the surface of 928Kg fertilizer granules, then add 40Kg of ammoniated humic acid and 10Kg of biomass charcoal, and finally powder 1Kg of microbial agent, add iron oxide black and 1Kg of forming agent, and mix well. .

[0032] The preparation method of the bonding auxiliary agent is to uniformly mix molasses fermented liquid, urea ammonium nitrate solution, and water according to the mass ratio of 4:3:3.

[0033] The organic matter content of the ammoniated humic acid is more than 65%, and the preparation method is to mix humic acid, ammonium bicarbonate and water according to the mass ratio of 10:3:3, mix and stir evenly, and seal and mature for 3 to 5 days.

[0034] The organic matter content of the biochar is more than 20%, and the preparation method is to carbonize straw and rice husk at high temperature and make it into powder, and the mesh number is more t...

Embodiment 2

[0036] Preparation of Multifunctional and Stable Coated Fertilizer

[0037] Spray 20Kg of bonding aid on the surface of 900Kg of fertilizer granules, then add 60Kg of ammoniated humic acid and 10Kg of biomass charcoal, and finally powder 9Kg of microbial agent, add 1Kg of anti-caking agent, and mix well.

[0038] The preparation method of the bonding auxiliary agent is to uniformly mix molasses fermented liquid, urea ammonium nitrate solution, and water according to the mass ratio of 4:3:3.

[0039] The organic matter content of the ammoniated humic acid is more than 65%, and the preparation method is to mix humic acid, ammonium bicarbonate and water according to the mass ratio of 10:3:3, mix and stir evenly, and seal and mature for 3 to 5 days.

[0040] The organic matter content of the biochar is more than 20%, and the preparation method is to carbonize straw and rice husk at high temperature and make it into powder, and the mesh number is more than or equal to 300 mesh.

Embodiment 3

[0042] Preparation of Multifunctional and Stable Coated Fertilizer

[0043] Spray 20Kg of bonding aid on the surface of 1000Kg of fertilizer particles, then add 40Kg of ammoniated humic acid and 10Kg of biomass charcoal, and finally powder 1Kg of microbial agent, add 1Kg of forming agent, and mix well.

[0044] The preparation method of the bonding auxiliary agent is to uniformly mix molasses fermented liquid, urea ammonium nitrate solution, and water according to the mass ratio of 4:3:3.

[0045] The organic matter content of the ammoniated humic acid is more than 65%, and the preparation method is to mix humic acid, ammonium bicarbonate and water according to the mass ratio of 10:3:3, mix and stir evenly, and seal and mature for 3 to 5 days.

[0046] The organic matter content of the biochar is more than 20%, and the preparation method is to carbonize straw and rice husk at high temperature and make it into powder, and the mesh number is more than or equal to 300 mesh.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com