Strong basic composite ion exchange resin material and preparation method thereof

A composite ion and exchange resin technology, applied in the direction of anion exchanger materials, etc., can solve the problems of low activity and low content of basic active groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

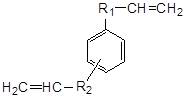

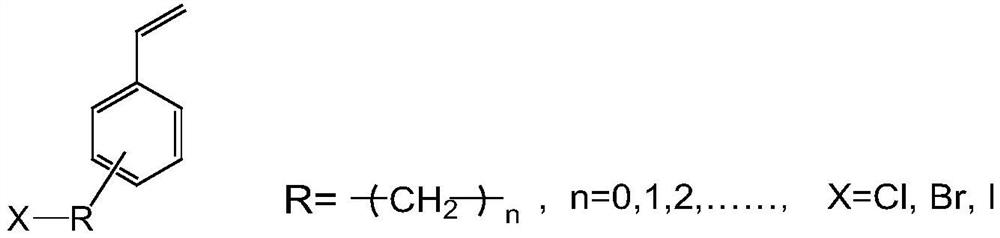

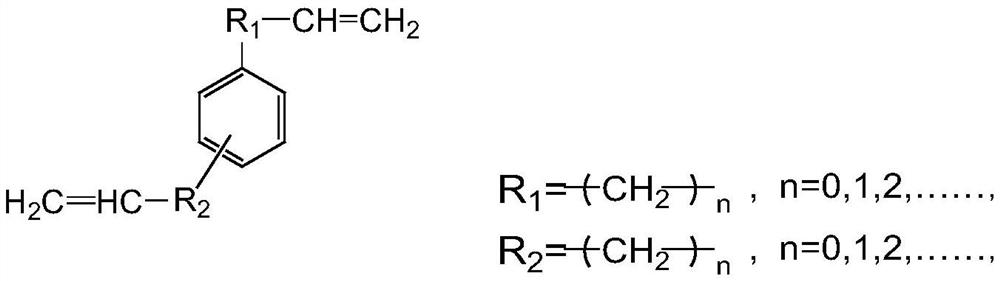

Method used

Image

Examples

Embodiment 1

[0044]Get 34 grams of p-iodomethylstyrene, 1.5 grams of divinylbenzene, 0.5 grams of benzoyl peroxide initiator and 2.5 grams of single-layer graphene, stir for 1 hour and mix evenly, take out 5 grams of mixed solution, add 0.8 gram of iodoform, shake and mix in a low-temperature water bath to obtain solution A, and the remaining mixed solution is set aside. Take a 500 ml three-neck flask and add 200 ml of deionized aqueous solution in which 2 g of polyvinyl alcohol has been dissolved. The previously prepared solution A was added dropwise, and the air was replaced by argon after being sealed, heated to 80°C, and reacted for 5 hours; then heated to 90°C, reacted for 5 hours, and finally heated to 98°C, reacted for 6 hours. After the reaction, pour out the upper liquid, wash it with hot water, then filter it, put it in an oven to dry at 80°C, and sieve it to collect the composite microspheres A with a particle size in the range of 0.35-0.60mm.

[0045] In a 250 ml three-neck fl...

Embodiment 2

[0048] Take 32 grams of 2-iodostyrene, 1.5 grams of divinylbenzene, 0.5 grams of benzoyl peroxide initiator and 2.5 grams of single-layer graphene, stir for 1 hour to mix evenly, take out 5 grams of mixed solution, add 0.8 grams of iodine In the same manner, shake and mix in a low-temperature water bath to obtain solution A, and the remaining mixed solution is set aside. Take a 500 ml three-neck flask and add 200 ml of deionized aqueous solution in which 2 g of polyvinyl alcohol has been dissolved. The previously prepared solution A was added dropwise, and the air was replaced by argon after being sealed, heated to 80°C, and reacted for 5 hours; then heated to 90°C, reacted for 5 hours, and finally heated to 98°C, reacted for 6 hours. After the reaction, pour out the upper liquid, wash it with hot water, then filter it, put it in an oven to dry at 80°C, and sieve it to collect the composite microspheres B with a particle size in the range of 0.35-0.60mm.

[0049] In a 250 ml ...

Embodiment 3

[0052] Get 16 grams of 2-iodostyrene, 17 grams of p-iodomethylstyrene, (the ratio of p-iodomethylstyrene and 2-iodostyrene is 1:1), 1.5 grams of divinylbenzene, 0.5 gram of benzoyl peroxide initiator and 2.5 grams of single-layer graphene, stirred for 1 hour and uniformly mixed, took out 5 grams of mixed solution, added 0.8 gram of iodoform, oscillated and mixed in a low-temperature water bath to obtain solution A, and the remaining mixed solution was set aside. Take a 500 ml three-neck flask and add 200 ml of deionized aqueous solution in which 2 g of polyvinyl alcohol has been dissolved. The previously prepared solution A was added dropwise, and the air was replaced by argon after being sealed, heated to 80°C, and reacted for 5 hours; then heated to 90°C, reacted for 5 hours, and finally heated to 98°C, reacted for 6 hours. After the reaction, pour out the upper liquid, wash it with hot water, then filter it, put it in an oven to dry at 80°C, and sieve it to collect the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com