Grease used for combustion gas plug valve and preparation method thereof

A technology of gas cock valve and lubricating grease, which is applied in the field of lubricating grease to achieve fast and full stirring, avoid aggregation, and good acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

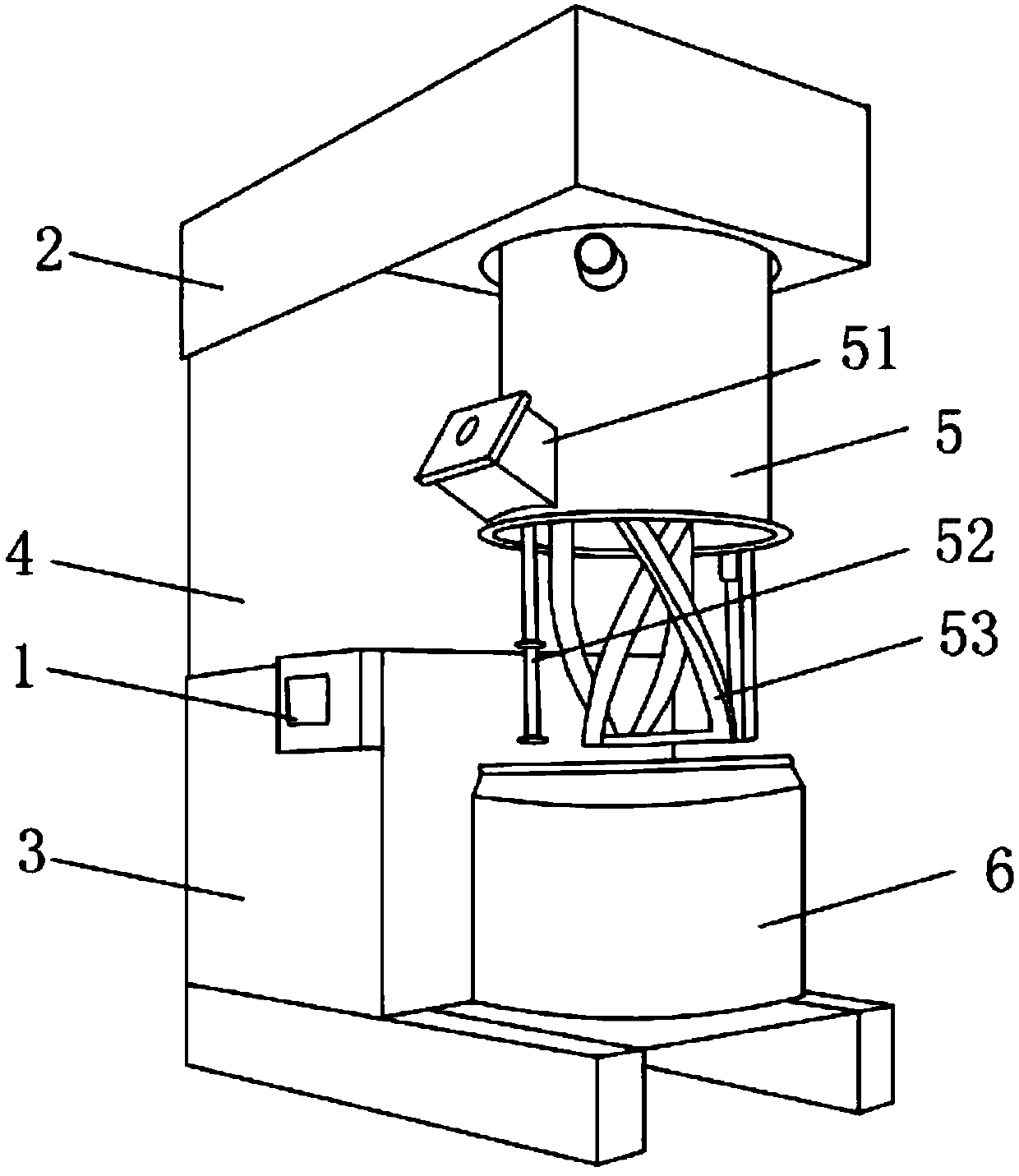

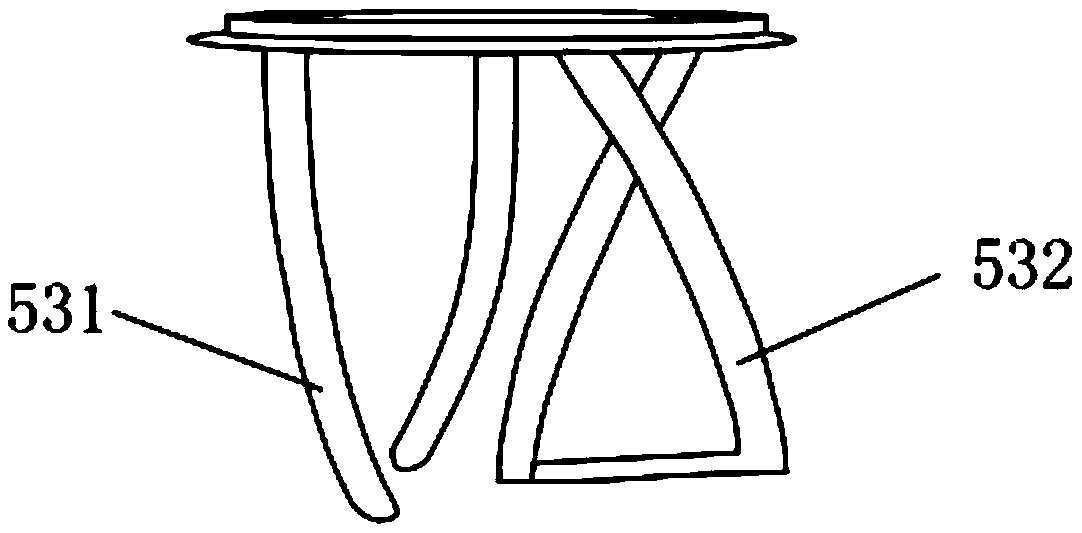

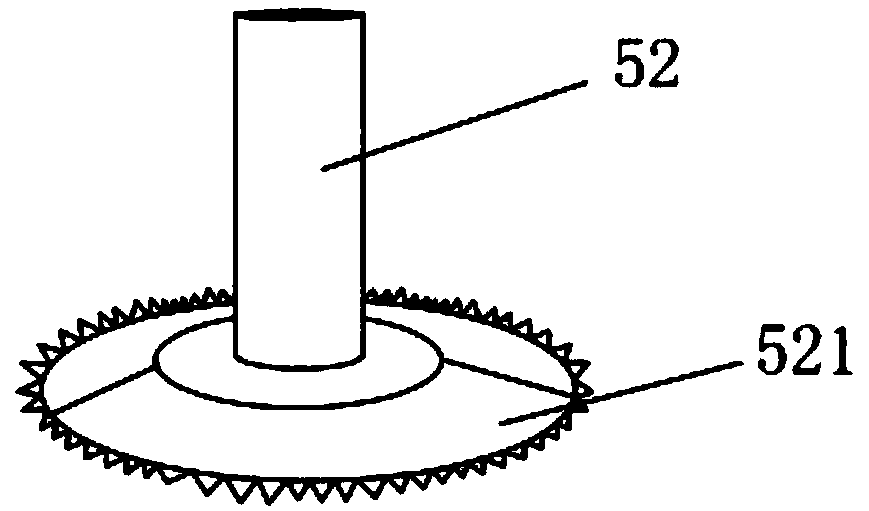

Image

Examples

Embodiment 1

[0045] A kind of lubricating grease for gas cock valve, described lubricating grease is prepared from the following raw materials by weight:

[0046] Silicone synthetic oil 80 parts

[0047] White amorphous silica gel powder 10 parts

[0048] 3 parts diphenylsilanediol

[0049] 10 parts ethanol

[0050] 1 part of 3,5-bis(1,1-dimethylethyl)-4-hydroxy-C7-9-branched chain phenylpropionate

[0051] Benzotriazole 0.5 parts

[0052] Molybdenum disulfide 1 part

[0053] Triethylamine 0.1 part

[0054] The preparation method of the grease for the gas valve cock comprises the following steps:

[0055] S1, preparation of modified synthetic oil

[0056] Take 80 parts of silicone synthetic oil and add it to the double planetary disperser, turn on the stirring paddle, add 3 parts of diphenylsilanediol and 10 parts of ethanol to the synthetic oil while stirring, keep it for 10 minutes after the addition, and raise the temperature to 75°C -85°C, keep warm for 5 minutes, then raise the ...

Embodiment 2

[0062] A kind of lubricating grease for gas cock valve, described lubricating grease is prepared from the following raw materials by weight:

[0063] Silicone synthetic oil 80 parts

[0064] White amorphous silica gel powder 12 parts

[0065] 4 parts diphenylsilanediol

[0066] 12 parts of ethylene glycol

[0067] Liquid octylbutyl diphenylamine 3 parts

[0068] Benzotriazole 0.5 parts

[0069] 1 part colloidal graphite

[0070] Solidamine 0.05 parts

[0071] The preparation method of the grease for the gas valve cock comprises the following steps:

[0072] S1, preparation of modified synthetic oil

[0073] Take 80 parts of silicone synthetic oil and add it to the double planetary disperser, turn on the stirring paddle, add 4 parts of diphenylsilanediol and 12 parts of ethylene glycol into the synthetic oil while stirring, keep it for 12 minutes after the addition, and raise the temperature to 75°C-85°C, keep warm for 5 minutes, then raise the temperature to 150°C-160°...

Embodiment 3

[0079] A kind of lubricating grease for gas cock valve, described lubricating grease is prepared from the following raw materials by weight:

[0080] Silicone synthetic oil 75 parts

[0081] White amorphous silica gel powder 12 parts

[0082] 4 parts diphenylsilanediol

[0083] Ethylene glycol 10 parts

[0084] Nonyl-N-(nonylphenyl)aniline 5 parts

[0085] N-acyl sarcosine 0.5 parts

[0086] 1 part polytetrafluoroethylene

[0087] Triethylamine 0.1 part

[0088] The preparation method of the grease for the gas valve cock comprises the following steps:

[0089] S1, preparation of modified synthetic oil

[0090] Take 75 parts of silicone synthetic oil and add it to the double planetary disperser, turn on the stirring paddle, add 4 parts of diphenylsilanediol and 10 parts of ethylene glycol to the synthetic oil while stirring, keep it for 20 minutes after the addition, and raise the temperature to 75°C-85°C, keep warm for 5 minutes, then raise the temperature to 150°C-160...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap