High-performance magnesium-aluminum-alloy cutting fluid and preparing method thereof

A magnesium-aluminum-aluminum alloy and cutting fluid technology, which is applied in lubricating compositions and the petroleum industry, can solve problems such as insufficient boundary extreme pressure lubricity, broken taps, discoloration of workpieces, etc., to achieve good anti-rust cleaning, reduce tool wear, and protect non-breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

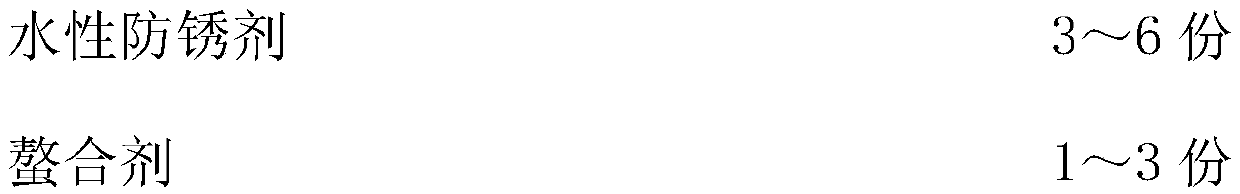

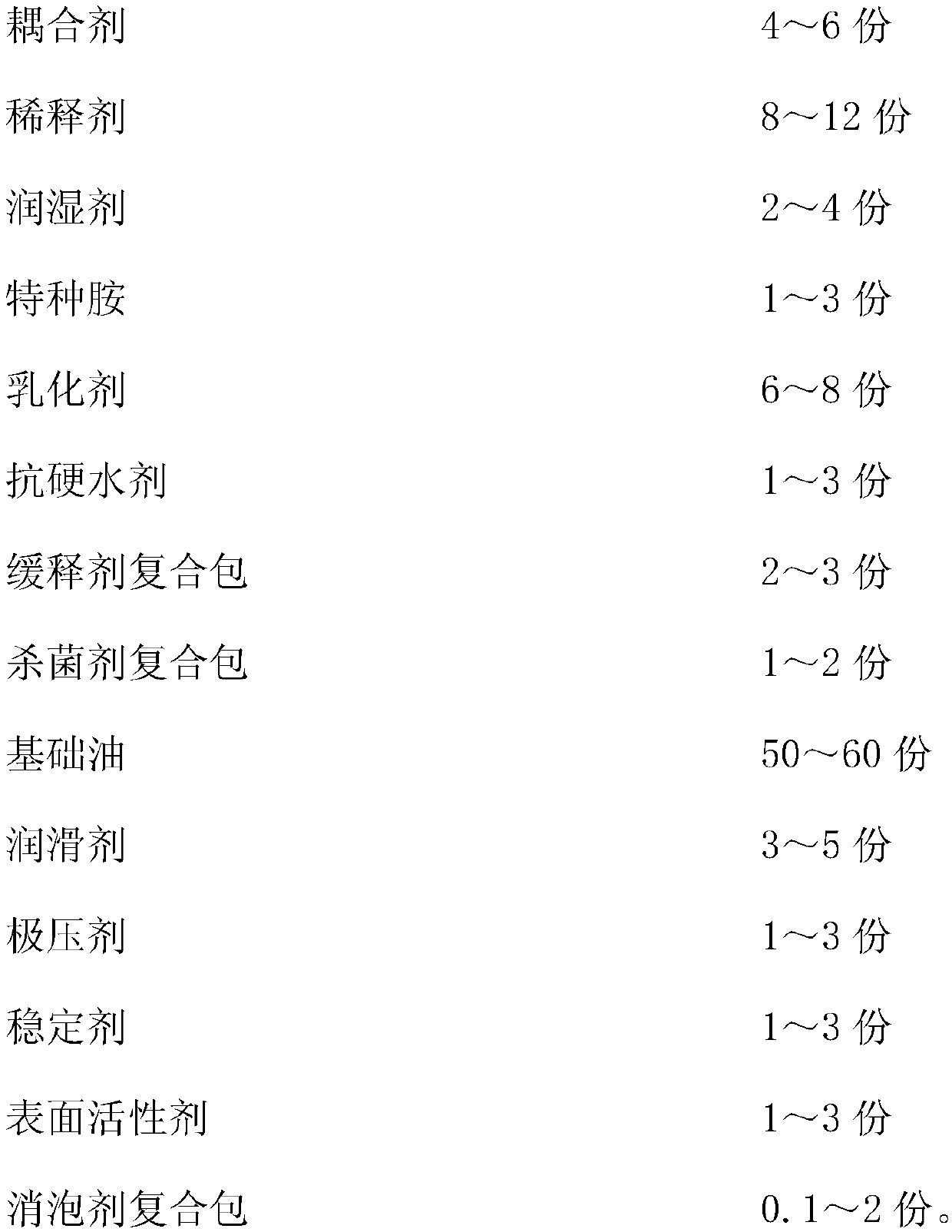

[0037] A high-performance magnesium-aluminum alloy cutting fluid provided in this embodiment includes the following components in parts by mass:

[0038]

[0039]

[0040] Specifically, the water-based antirust agent is a mixture of one or more of boric acid, neodecanoic acid, and tribasic acid, and the tribasic acid is a tribasic polycarboxylic acid provided by Hangzhou Lvpu Chemical Technology Co., Ltd. TAT730; the chelating agent is ETDA-2Na; the coupling agent is one or a mixture of diethanolamine and triethanolamine; the diluent is deionized water; the wetting agent is glycerin. The special amine is the AMP-95 multifunctional additive provided by Dow Chemical Company of the United States, and its main component is 2-amino-2-methyl-1-propanol containing 5% water by mass. Described emulsifier is the mixing of one or both in the low-foam high-efficiency emulsifier Genifol SA6062 and the Genimus 2815 amide emulsifier provided by Shanghai Shangqing Industry Co., Ltd.; th...

specific Embodiment 2

[0050]A high-performance magnesium-aluminum alloy cutting fluid provided in this embodiment includes the following components in parts by mass:

[0051]

[0052] The concrete raw material kind of above-mentioned each component is identical with concrete embodiment 1.

[0053] The preparation method of a high-performance magnesium-aluminum alloy cutting fluid provided in this embodiment is the same as that of the specific embodiment 1.

specific Embodiment 3

[0054] A high-performance magnesium-aluminum alloy cutting fluid provided in this embodiment includes the following components in parts by mass:

[0055]

[0056] The concrete raw material kind of above-mentioned each component is identical with concrete embodiment 1.

[0057] The preparation method of a high-performance magnesium-aluminum alloy cutting fluid provided in this embodiment is the same as that of the specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com