Fabricated concrete building grouting pretreatment construction method

A concrete building and construction method technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of inconvenient construction on site, affecting the quality of grouting, delaying the construction period, etc., to improve construction efficiency and quality, and ensure grouting effect, the effect of ensuring the quality of the connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In a construction project, the prefabricated concrete shear wall structure system is mainly used. Before the grouting construction, the iron wire is used to check whether the inlet and outlet of the grout are blocked, so as to find obvious abnormalities. During the grouting construction, there were two grout outlets that could not produce grout. After the emergency dredging on site, the grout still could not be produced. We had to chisel off the edge sealing layer of the seat grout, and use a high-pressure water gun to wash off the grouting material inside the prefabricated components and re-install the seal. Side, to the site construction caused a lot of trouble, delaying the construction period.

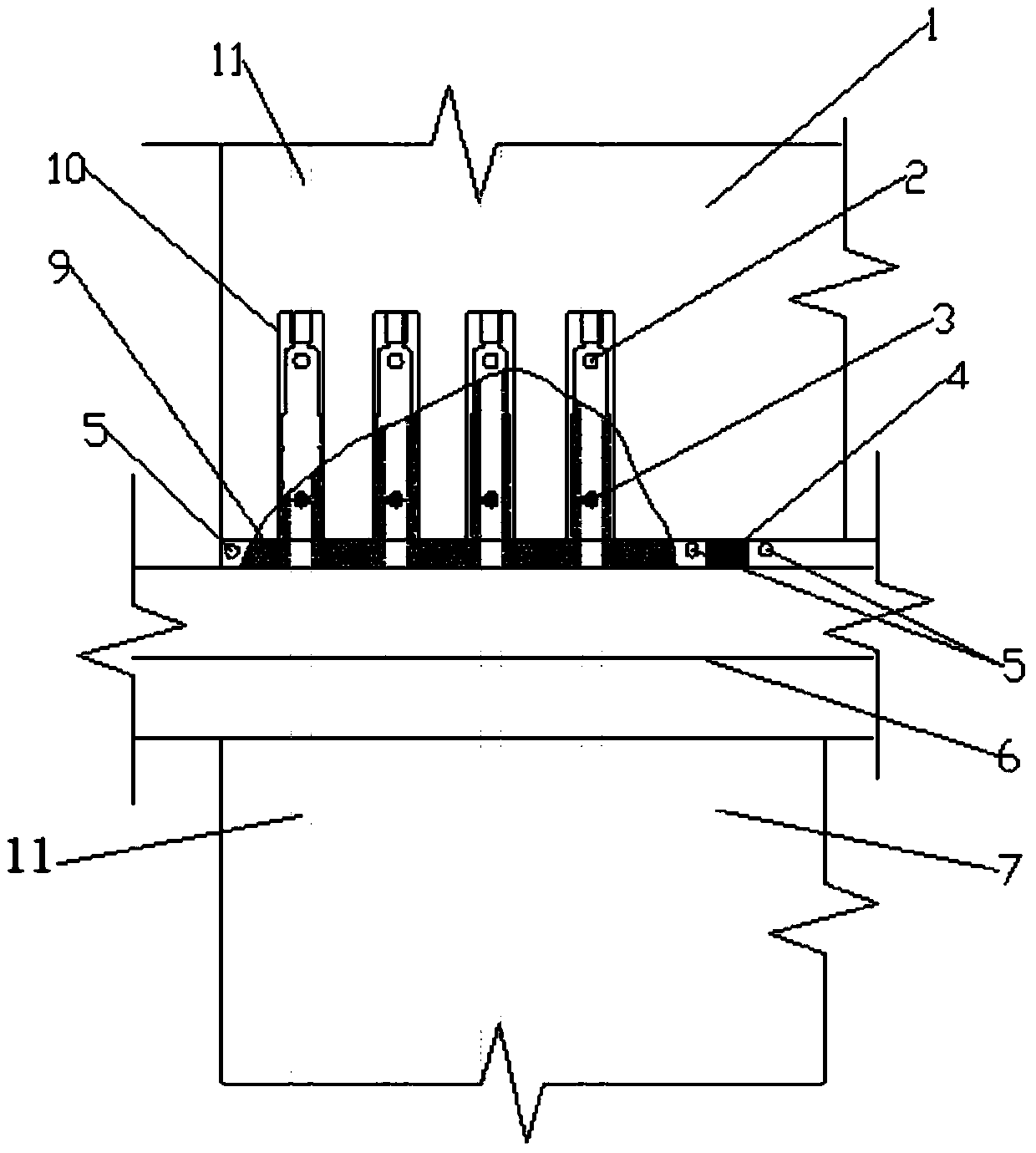

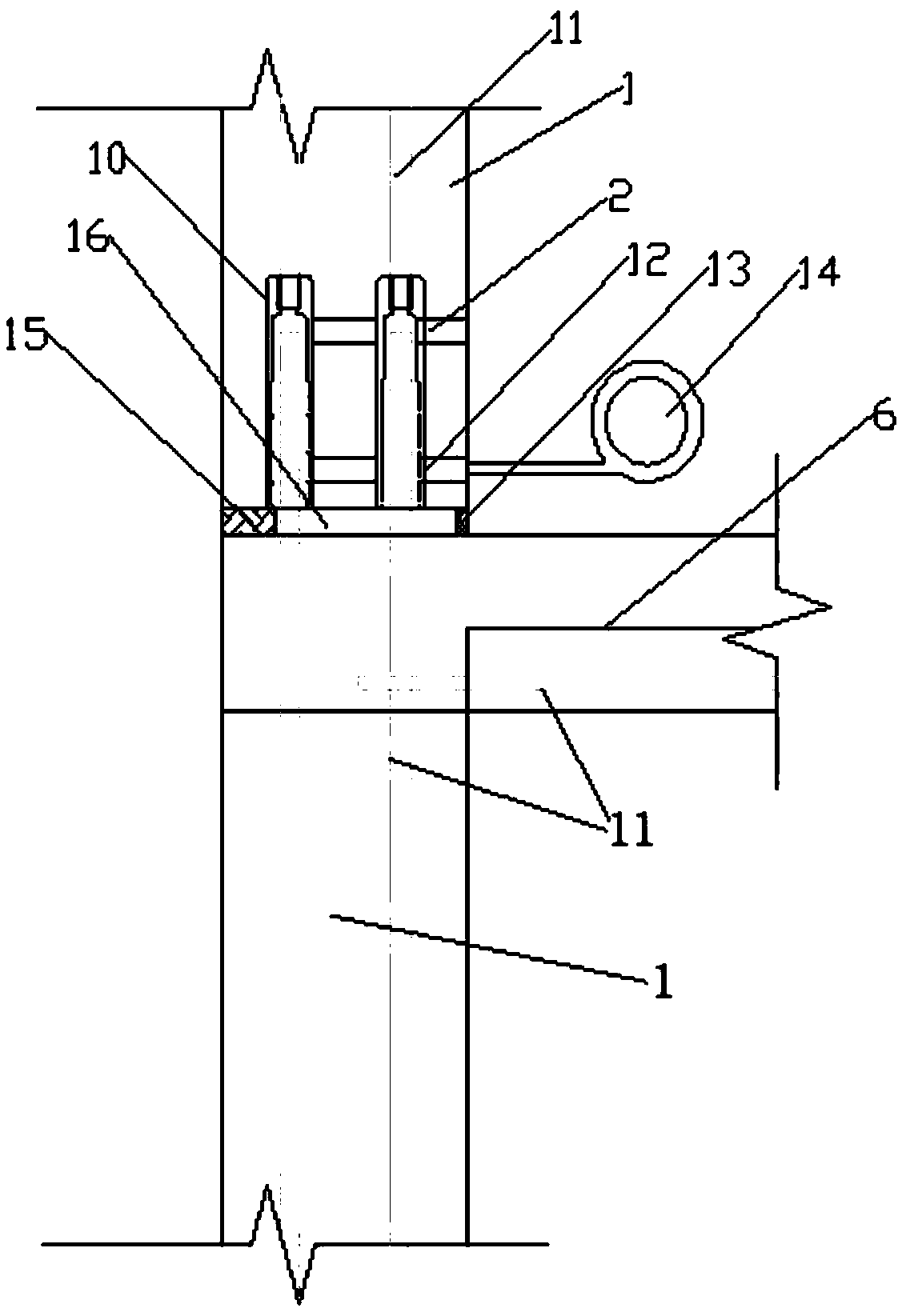

[0055] Adopting the construction pretreatment method of the present invention: after completing the hoisting and fixing of the prefabricated components and the edge sealing of the prefabricated components and the bottom plate, before the grouting construction, use the ultraso...

Embodiment 2

[0057] In a construction project, the prefabricated concrete shear wall structure system is mainly used. Due to the summer construction, the outdoor ambient temperature is about 35°C, and the prefabricated components are exposed to the sun after hoisting. Before wetting, directly grouting, the water in the slurry will be lost quickly, the grouting pressure will be very high, the phenomenon of pipe plugging and edge sealing material cracking will occur on site, which will bring great inconvenience to the site construction.

[0058] Use the grouting pretreatment construction process of the present invention instead: After the prefabricated component is hoisted and fixed, and the edge sealing between the prefabricated component and the bottom plate is completed, before the grouting construction, use the ultrasonic atomizer 14 and the bottom of the grouting sleeve 10 in the middle of the prefabricated component 1 After checking and confirming that the pulp inlet and outlet are not ...

Embodiment 3

[0060] In a construction project, the prefabricated column grouting bottom grouting construction method is adopted. Due to winter construction, the outdoor temperature is about 3°C. The grouting pretreatment construction process of the present invention: after the prefabricated components are hoisted and fixed, and the prefabricated components and the bottom plate are sealed Finally, before the grouting construction, use the ultrasonic atomizer 14 to connect with the grout inlet 12 at the bottom of the grouting sleeve 10 in the middle of the prefabricated component 1. Water vapor is passed through the port, and steam emerges from the other pulp inlets and outlets, which should be blocked in time with rubber plugs. Before the last pulp outlet is blocked, the humidification amount of the atomizer should be controlled at 20Kg / h, and the temperature of the atomizer should be controlled at 65 ℃, and the steaming time is about 15 minutes. The wetting of the bottom of the air outlet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com