Method for pre-insertion of lithium of lithium ion supercapacitor negative electrode

A technology of supercapacitor and pre-intercalation of lithium, applied in the field of electrochemical energy storage, can solve the problem of large attenuation of ion concentration, and achieve the effects of simplifying assembly process, reducing cost and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

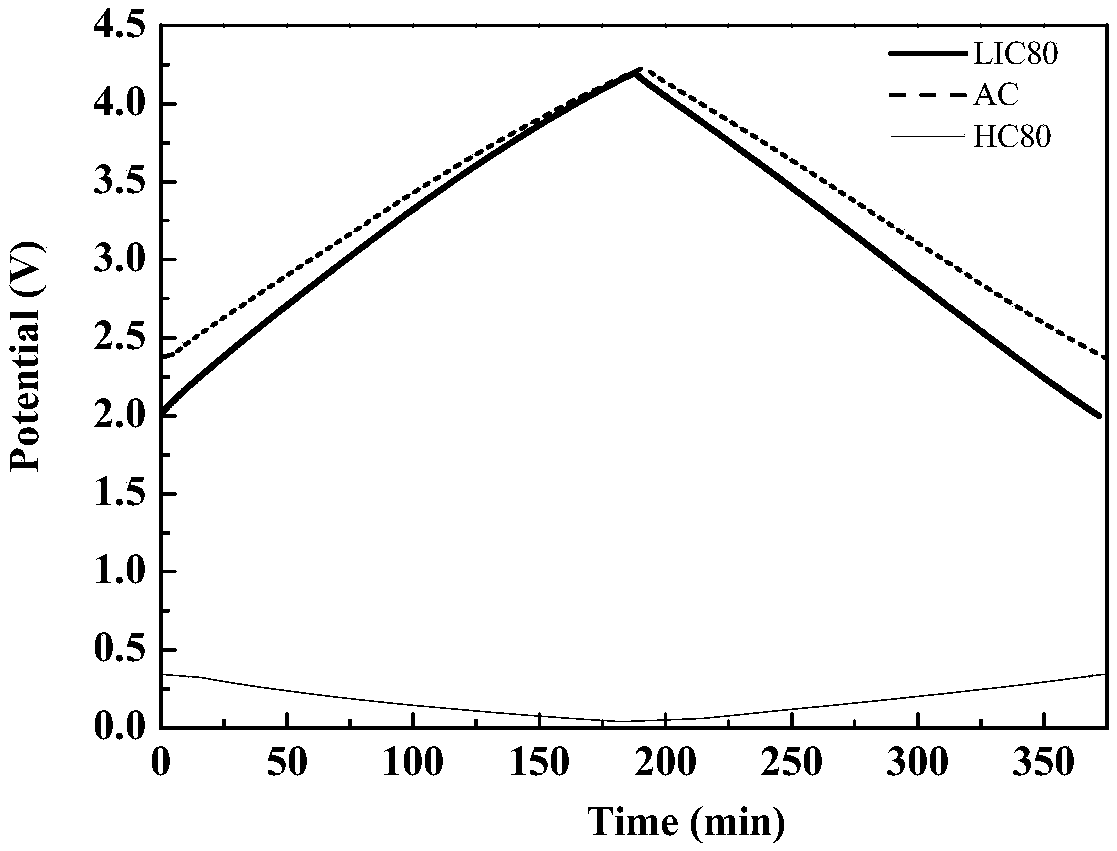

[0026] Add 11% lithium nitride to the activated carbon positive electrode, use hard carbon as the negative electrode, 1M LiPF6 / EC:DEC (volume ratio 1:1) as the electrolyte, and cellgard2400 as the diaphragm to assemble the lithium-ion supercapacitor. Through the first round of charging, the negative electrode can be pre-intercalated with lithium at a depth of 80%. The voltage range of the capacitor is 2-4.2V, and the charge-discharge curve has good symmetry (see attached figure 2 shown), the Coulombic efficiency is close to 100%, and the specific energy reaches 31Wh / kg.

Embodiment 2

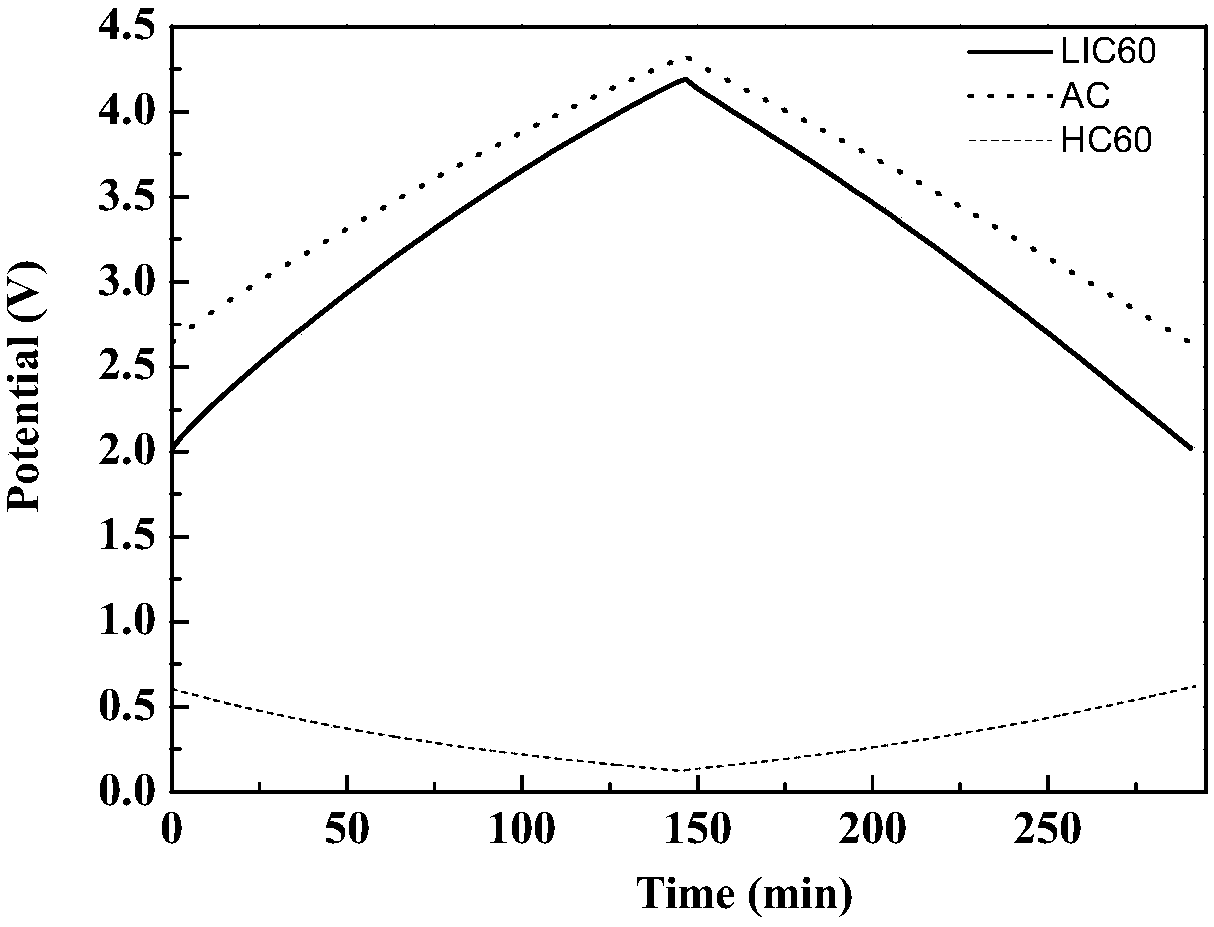

[0028] Add 6% lithium nitride to the active carbon positive electrode, use hard carbon as the negative electrode, 1M LiPF6 / EC:DEC (volume ratio 1:1) as the electrolyte, and cellgard2400 as the diaphragm to assemble the lithium-ion supercapacitor. Through the first cycle of charging, the negative electrode can be pre-intercalated with lithium at a depth of 60%. The voltage range of the capacitor is 2-4.2V, and the charge-discharge curve has good symmetry (see attached image 3 shown), the Coulombic efficiency is close to 100%, the specific energy reaches 25Wh / kg, and the discharge capacity at 30C discharge rate can be maintained at more than 80% of that at 1C discharge rate.

Embodiment 3

[0030] Add 15% lithium azide to the active carbon positive electrode, use hard carbon as the negative electrode, 1M LiPF6 / EC:DEC (volume ratio 1:1) as the electrolyte, and cellgard2400 as the diaphragm to assemble the lithium-ion supercapacitor. Through the first cycle of charging, the negative electrode is pre-intercalated with lithium at a depth of 85%. The voltage range of the capacitor is 2.8-4.2V. The charge-discharge curve is symmetrical, the Coulombic efficiency is close to 100%, and the specific energy reaches 17Wh / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com