Welded type ceramic artificial elbow joint

A welded, elbow-joint technology, applied in the direction of elbow joints, knee joints, joint implants, etc., can solve the problems of polymer thickness reduction, ceramic prosthesis is fragile, and has no clinical application, so as to reduce the quality and reduce the Fragmentation risk, effect of light movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

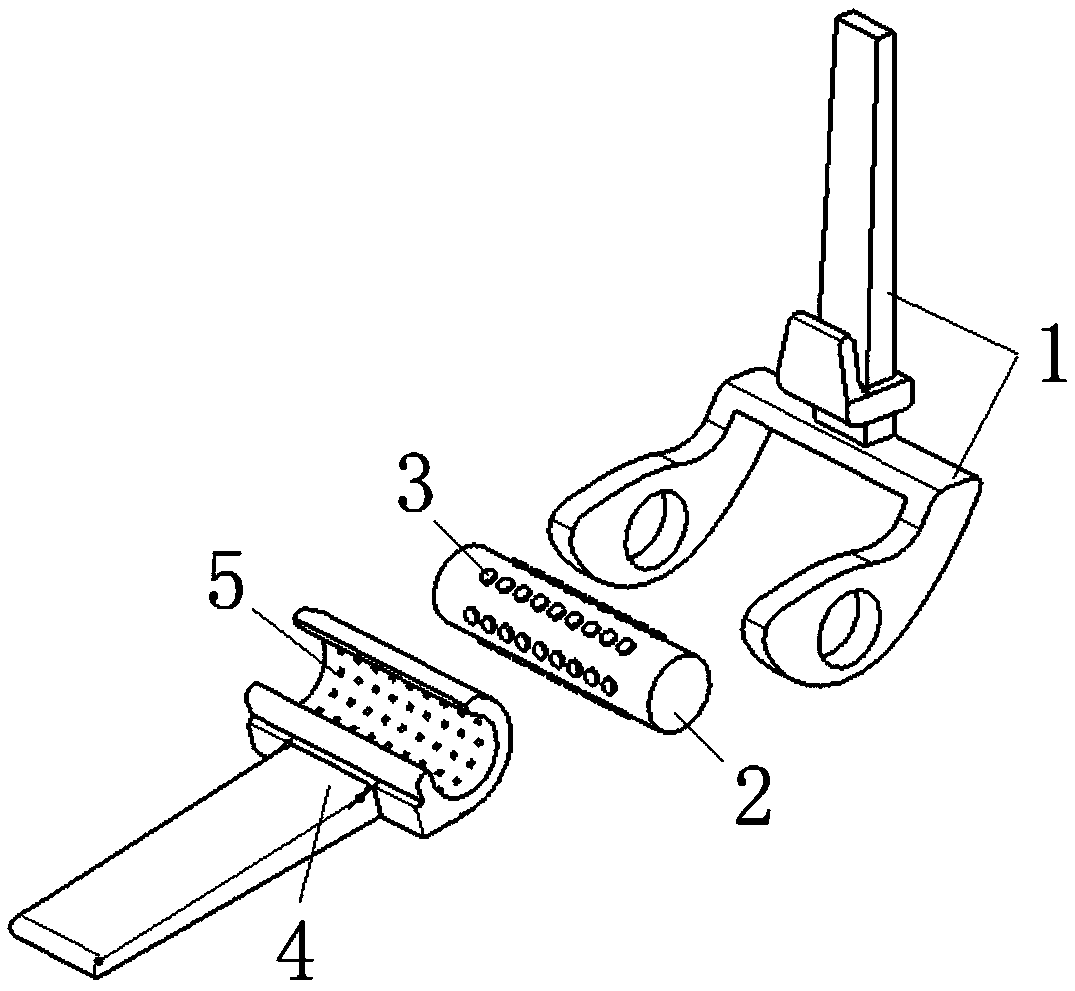

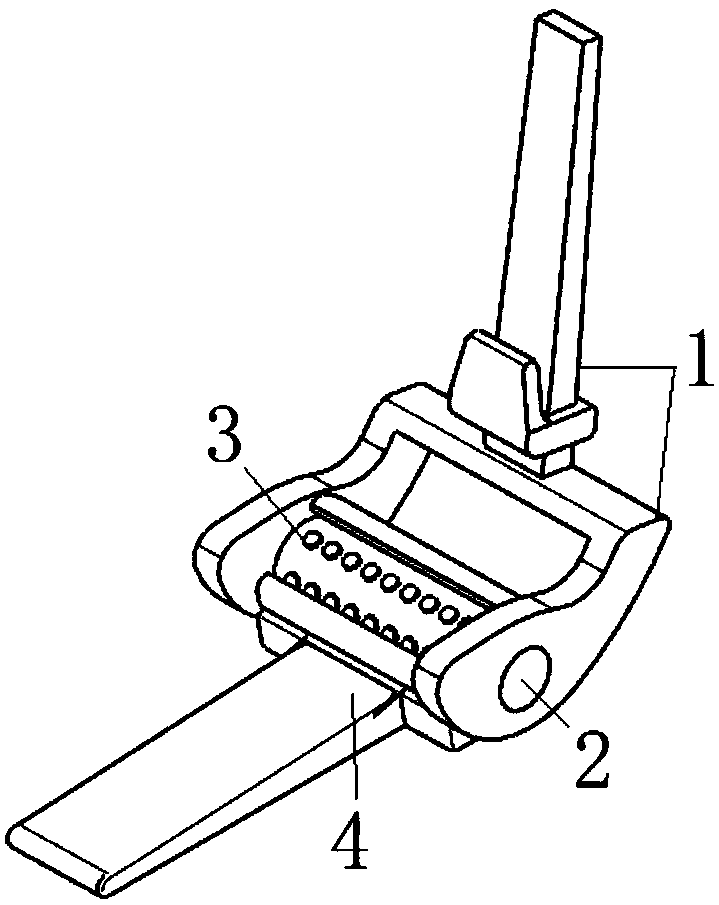

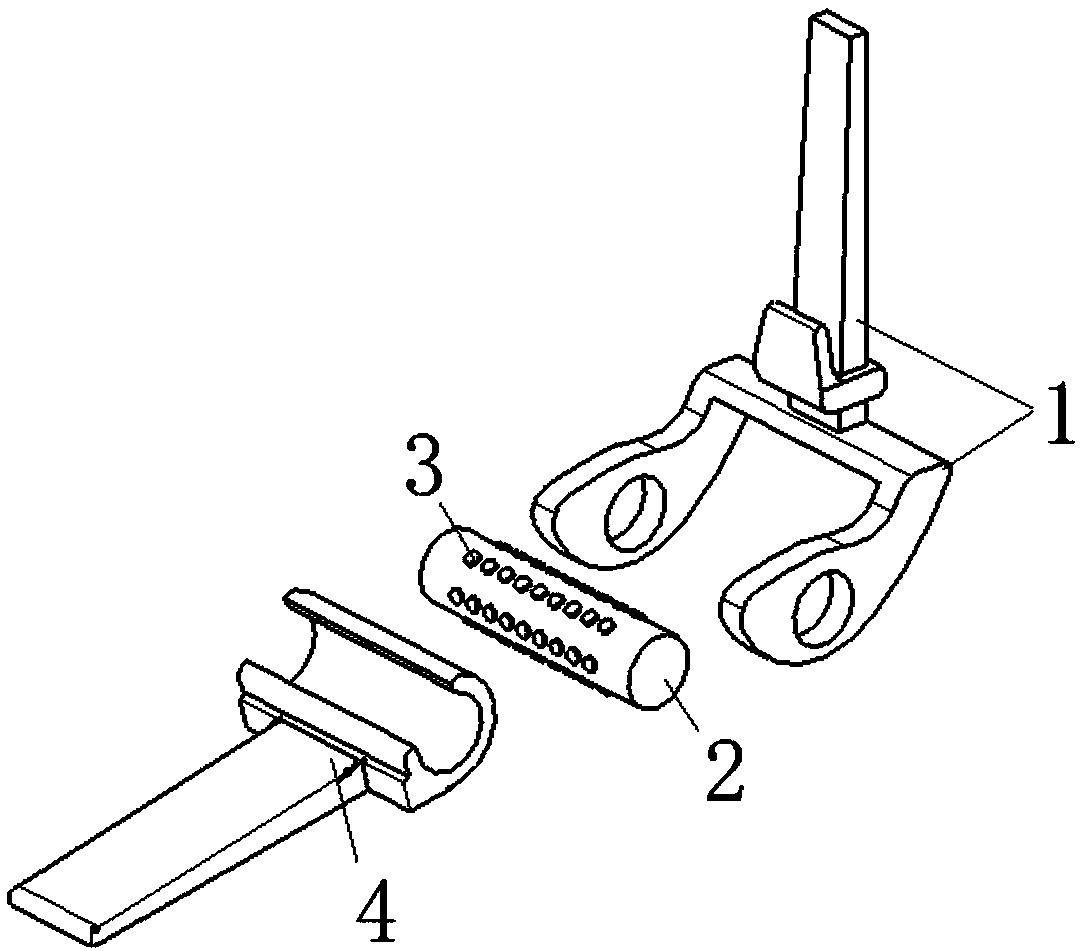

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0028] Such as Figure 1 to Figure 4 As shown, the welded ceramic artificial elbow joint includes a humeral prosthesis 1, an ulnar prosthesis 4, a shaft 2 and a ceramic sheet 3, and the shaft tube and the shaft arranged in the shaft tube are passed between the humeral prosthesis 1 and the ulnar prosthesis 4. 2 are connected, the shaft 2 and the shaft cylinder are relatively rotatable, and the outer surface of the shaft is welded with a protruding ceramic sheet. The outer surface of the ceramic sheet is in contact with the inner surface of the shaft cylinder to form a friction pair, so that the humeral prosthesis and the ulnar prosthesis The body can rotate relative to each other.

[0029] The ceramic sheet 3 is a bioceramic, and the ceramic sheet is a group of scattered ceramic sheets. The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com