Integrated sewage treatment equipment

A technology of sewage treatment equipment and aeration equipment, applied in the field of water pollution control, can solve the problems of prolonging the backwashing time of membrane modules, low sewage treatment efficiency, and large operating load, so as to reduce sludge disposal costs and reduce fouling Chance, the effect of reducing the operating load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

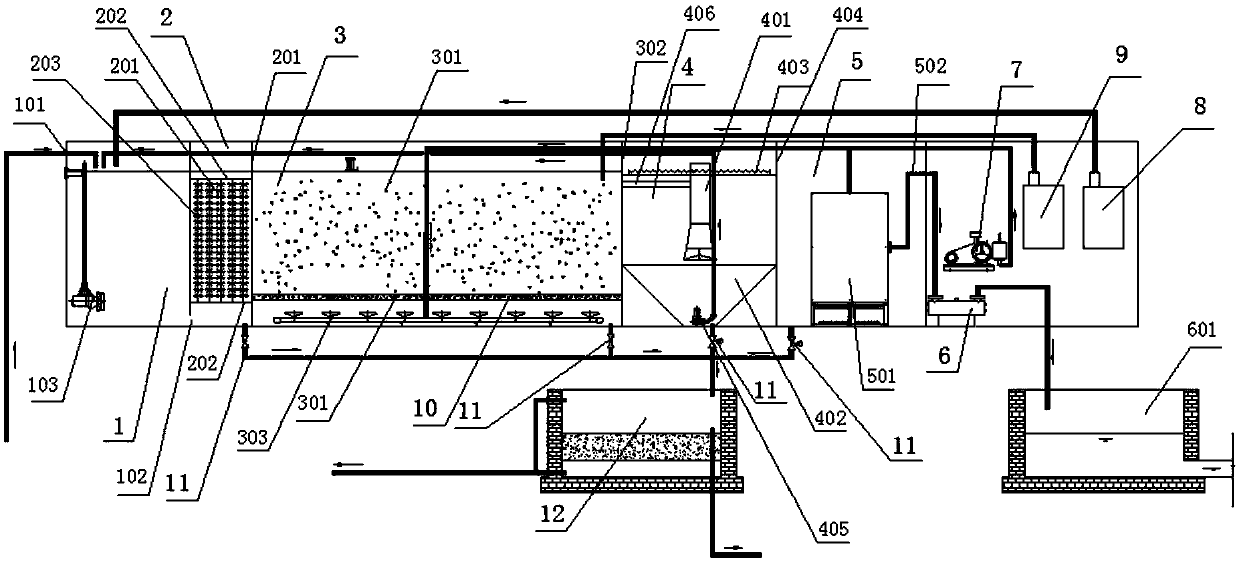

[0043] Such as figure 1 As shown, the integrated sewage treatment equipment includes anoxic pool 1, anaerobic pool 2, aerobic pool 3, sedimentation pool 4, and membrane reaction pool 5 connected sequentially from front to back. Anoxic pool 1 is provided with a water inlet 101 , the aerobic pool 3 is provided with an overflow port 302, the anoxic pool 1 is connected to the anaerobic pool 2 through the first water outlet 102 located at its lower part, and the anaerobic pool 2 is connected through the second water outlet 201 located at its upper part The oxygen tank 3 is provided with a connecting pipe 406 on the overflow port 302, and a central cylinder 401 is provided in the sedimentation tank 4, and the connecting pipe 406 is connected to the central cylinder 401, so the sedimentation tank 4 is connected to the aerobic tank 3 through the overflow port 302.

[0044] The anoxic pool 1 is provided with a stirrer 103 , and the anoxic pool 1 is connected to a carbon source dosing d...

Embodiment 2

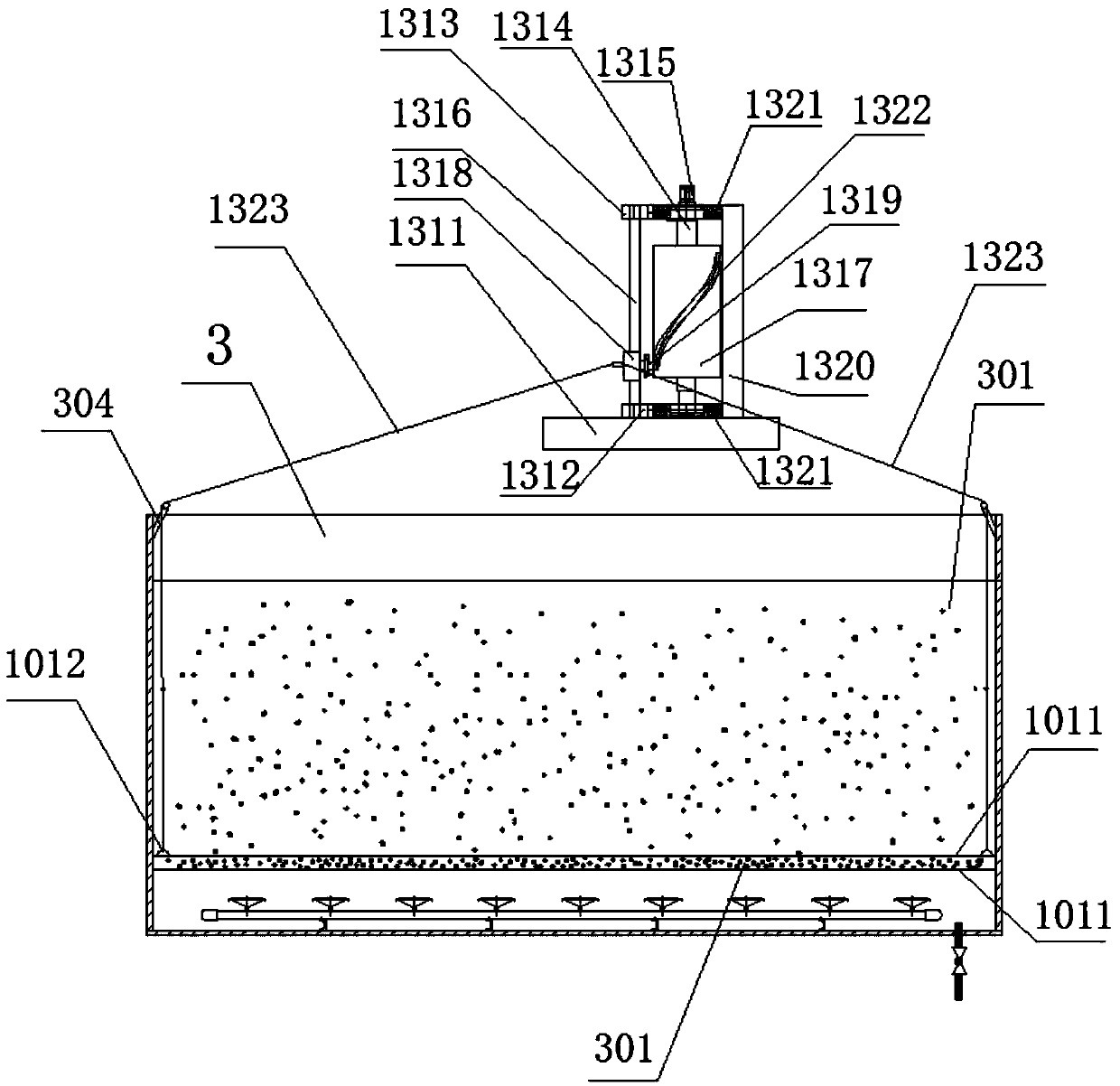

[0054] see Figure 2-5 , on the basis of Embodiment 1, this embodiment adds the following features:

[0055] It also includes a lifting device 13 located above the aerobic pool 3. The lifting device 13 includes a placement table 1311, a bottom plate 1312, a top plate 1313, a circular shaft 1314, a motor 1315, a slide bar 1316, a drum 1317, a slider 1318, a guide The column 1319, the placing table 1311 is set above the aerobic pool 3 through the base height higher than the aerobic pool 3, the bottom plate 1312 is arranged on the top of the placing table 1311, the top plate 1313 is connected to the placing table 1311 through the support rod 1320, and The top plate 1313 is located above the bottom plate 1312, the bottom plate 1312 and the top plate 1313 are embedded with bearings 1321, one end of the circular shaft 1314 is inserted into the bearing 1321 in the bottom plate 1312, and the other end passes through the bearing 1321 in the top plate 1313 upwards and then penetrates th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com