Concrete medium erosion resistant additive based on in-situ reaction encapsulation technology and preparation method

An in-situ reaction and concrete technology, applied in the field of building materials, can solve the problems of reduced diffusion coefficient, questionable effect, unfavorable automatic release of high active substances, etc. The effect of coefficient reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

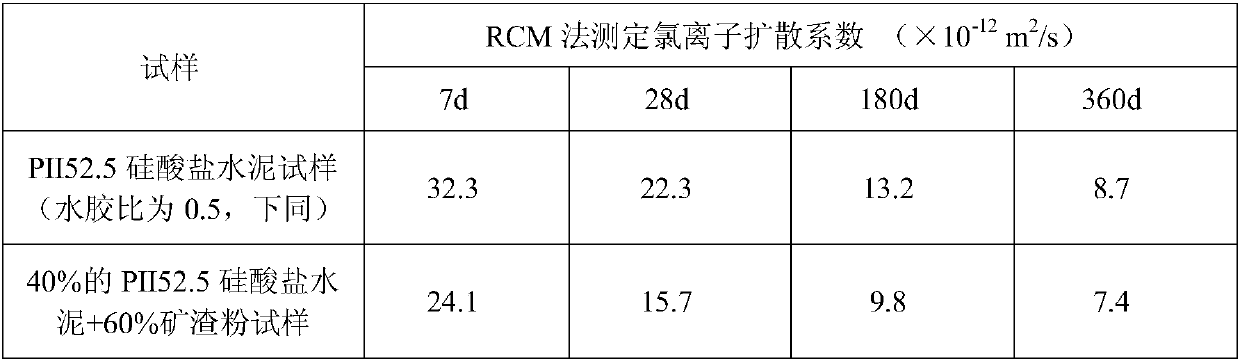

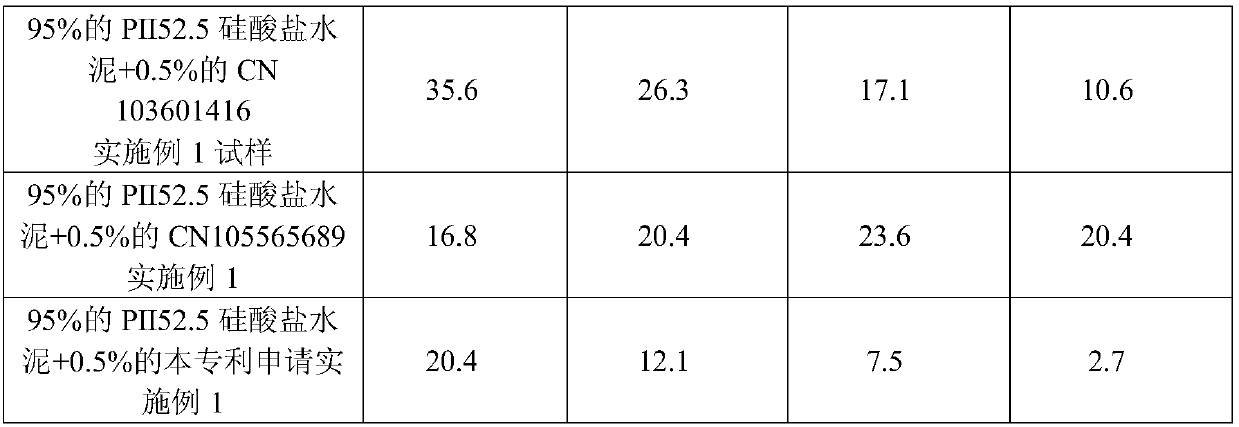

Examples

Embodiment 1

[0035] A kind of concrete anti-medium erosion admixture based on in-situ reaction encapsulation technology, it comprises the following steps:

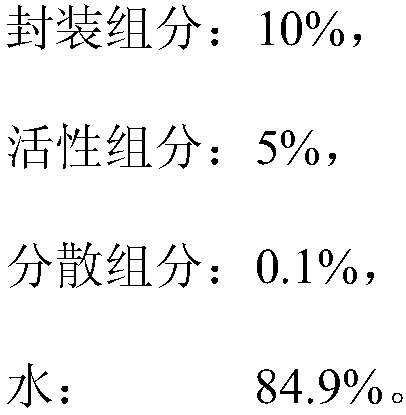

[0036] The admixture is composed of encapsulation components, active components, dispersion components, water

[0037]

[0038] Packaging components: Nanjing Chemical Reagent Co., Ltd., magnesium chloride (chemically pure), aluminum chloride (chemically pure), sodium carbonate (chemically pure), sodium hydroxide (chemically pure); Shanghai Aladdin Biochemical Technology Co., Ltd., ten Hexaalkyltrimethylammonium bromide (chemically pure).

[0039] Active ingredient: Shanghai Aladdin Biochemical Technology Co., Ltd., silica sol (average particle size 5nm, 30% concentration).

[0040] Dispersion component: Jiangsu Subote New Material Co., Ltd., PCE-801 (20% concentration).

[0041] Water: deionized water

[0042] Preparation method: (1) Add magnesium chloride and aluminum chloride to a certain amount of water to prepare Mg 2+ At a ...

Embodiment 2

[0049] A kind of concrete anti-medium erosion admixture based on in-situ reaction encapsulation technology, it comprises the following steps:

[0050] The admixture is composed of encapsulation components, active components, dispersion components, water

[0051]

[0052] Packaging components: Nanjing Chemical Reagent Co., Ltd., magnesium nitrate (chemically pure), aluminum nitrate (chemically pure), potassium carbonate (chemically pure), potassium hydroxide (chemically pure); Shanghai Aladdin Biochemical Technology Co., Ltd., A Amide (chemically pure).

[0053] Active ingredient: Nanjing Wanqing Huabo Instrument Co., Ltd., silica sol (average particle size 3nm, 20% concentration).

[0054] Dispersion component: Jiangsu Subote New Material Co., Ltd., PCE-403 (20% concentration).

[0055] Water: deionized water

[0056] Preparation method: (1) Add magnesium nitrate and aluminum nitrate to a certain amount of water to prepare Mg 2+ At a concentration of 1.5 mol / l, Al 3+ A...

Embodiment 3

[0063] A kind of concrete anti-medium erosion admixture based on in-situ reaction encapsulation technology, it comprises the following steps:

[0064] The admixture is composed of encapsulation components, active components, dispersion components, water

[0065]

[0066] Packaging components: Nanjing Chemical Reagent Co., Ltd., magnesium sulfate (chemically pure), aluminum sulfate (chemically pure), sodium carbonate (chemically pure), ammonia (chemically pure); Shanghai Aladdin Biochemical Technology Co., Ltd., N-form Dimethylformamide (chemically pure), dimethylformamide (chemically pure).

[0067] Active ingredient: Nanjing Wanqing Huabo Instrument Co., Ltd., silica sol (average particle size 5nm, 35% concentration).

[0068] Dispersion component: Jiangsu Subote New Material Co., Ltd., PCE-650 (20% concentration).

[0069] Water: deionized water

[0070] Preparation method: (1) Add magnesium sulfate and aluminum sulfate to a certain amount of water to prepare Mg 2+ At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com