Concrete Aggressive Medium Transmission Inhibiting Material and Its Preparation Method and Application

A kind of erosive and concrete technology, which is applied in the field of concrete erosive media transmission inhibition materials, can solve the problems of non-water-soluble components and limited concrete effect, and achieve the effect of changing surface tension, improving mechanical properties, and improving impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

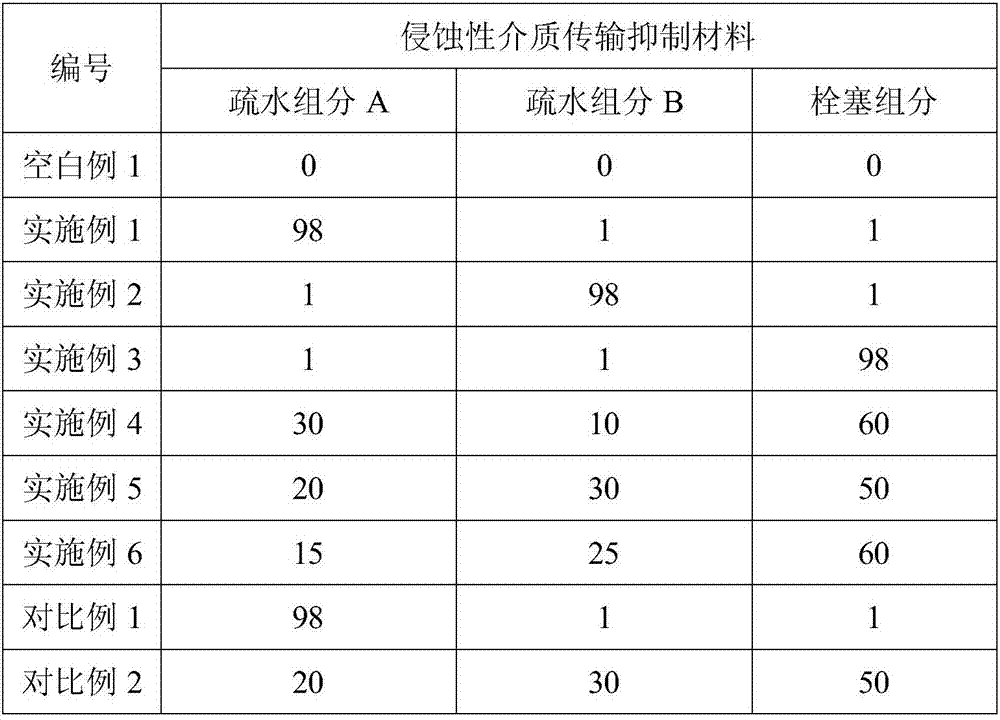

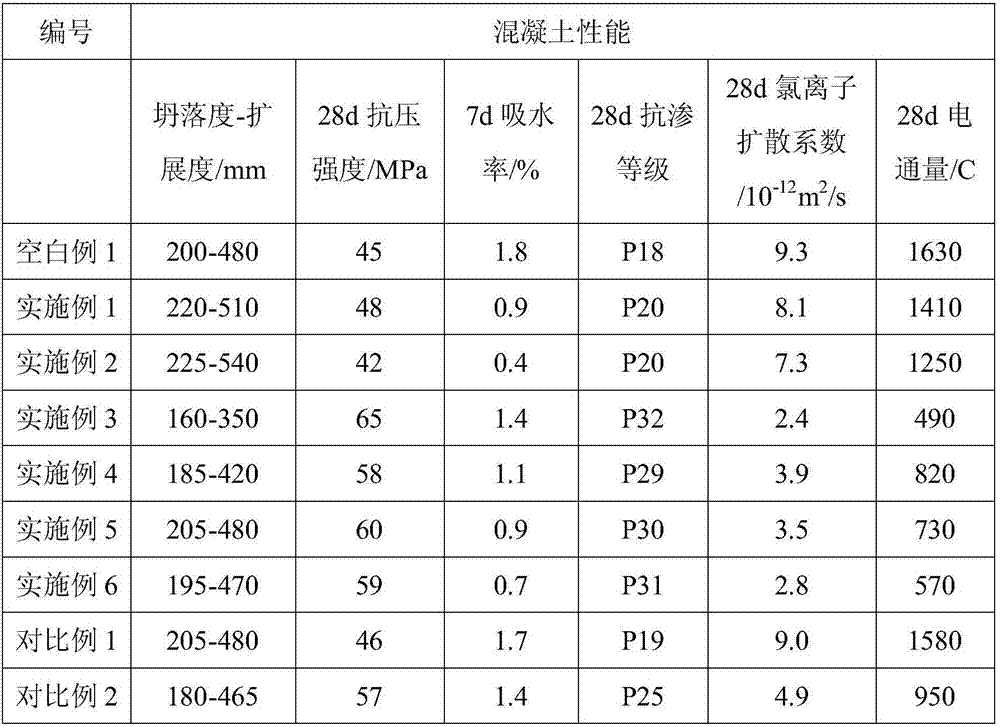

Examples

Embodiment 1

[0029] (1) Synthetic hydrophobic component A

[0030] Add 0.5 parts by weight of cetyl alcohol to 50 parts by weight of distilled water, stir at room temperature for 60 min, then add 15 parts by weight of calcium stearate, and stir under reflux at 20-50° C. for 100 min.

[0031] (2) Synthesis of hydrophobic component B

[0032] Add 1 part by weight of dodecanoic acid to 50 parts by weight of distilled water, stir at room temperature for 30 minutes, then add 15 parts by weight of isooctyltriethoxysilane, and stir under reflux at 20-50°C for 1 hour.

[0033] (3) Using 15 parts by weight of nano-silica and 100 parts by weight of water, and dispersing by ultrasonic technology for 30 minutes, an aqueous dispersion of embolism components was prepared for use.

[0034] (4) First compound 98 parts by weight of hydrophobic component A and 1 part by weight of B, and then compound the synthesized hydrophobic component and 1 part by weight of plugging component to prepare the concrete er...

Embodiment 2

[0036] (1) Synthetic hydrophobic component A

[0037] Add 2 parts by weight of sorbitan fatty acid ester to 100 parts by weight of distilled water, stir at room temperature for 120 minutes, then add 30 parts by weight of stearic acid amine, and reflux and stir at 20-50° C. for 100 minutes.

[0038] (2) Synthesis of hydrophobic component B

[0039]Add 1 part by weight of polyoxyethylene sorbitan monooleate to 100 parts by weight of distilled water, stir at room temperature for 30 minutes, then add 20 parts by weight of isobutyltriethoxysilane, and reflux at 20-50°C Stir for 3h.

[0040] (3) Use 5% mass concentration of silica sol to make an aqueous dispersion of embolism components for later use.

[0041] (4) First compound 1 weight part of the hydrophobic component A and 98 weight parts B, and then compound the synthesized hydrophobic component and 1 weight part of the plugging component to prepare the concrete erosion medium transmission inhibiting material.

Embodiment 3

[0043] (1) Synthetic hydrophobic component A

[0044] Add 5 parts by weight of cetyl alcohol into 200 parts by weight of distilled water, stir at room temperature for 120 min, then add 50 parts by weight of sodium palmitate, and stir under reflux at 20-50° C. for 120 min.

[0045] (2) Synthesis of hydrophobic component B

[0046] Add 3 parts by weight of tetradecanoic acid into 150 parts by weight of distilled water, stir at room temperature for 90 min, then add 40 parts by weight of dimethyldiethoxysilane, and stir under reflux at 20-50° C. for 3 h.

[0047] (3) 30 parts by weight of nano-calcium carbonate and 100 parts by weight of water were used, and ultrasonic technology was used to disperse for 120 minutes to prepare an aqueous dispersion of embolism components for later use.

[0048] (4) First compound 1 part by weight of hydrophobic component A and 1 part by weight of B, and then compound the synthesized hydrophobic component and 98 parts by weight of plugging compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com