A low-wetting, high-durability composite Portland cement and its preparation method

A composite silicate and Portland cement technology, applied in the field of cement, can solve the problems of continuous hydration and compressive strength development of unfavorable cementitious materials, limited depth of surface coating protection, and damage to the integrity of cement paste. Achieve the effect of high resistance to sulfate corrosion, low porosity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

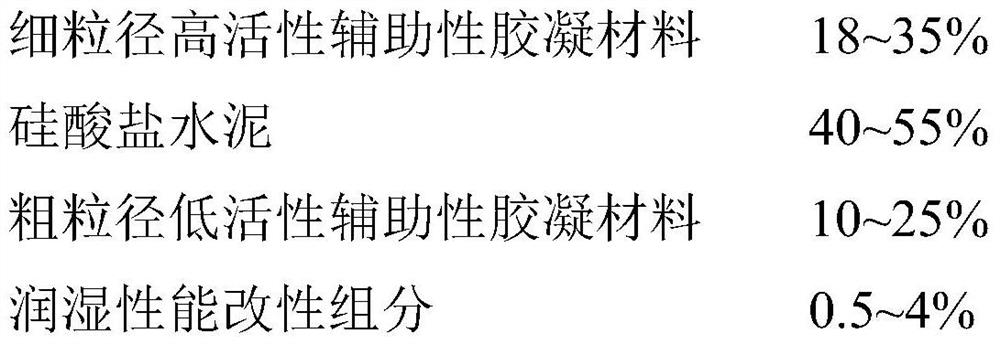

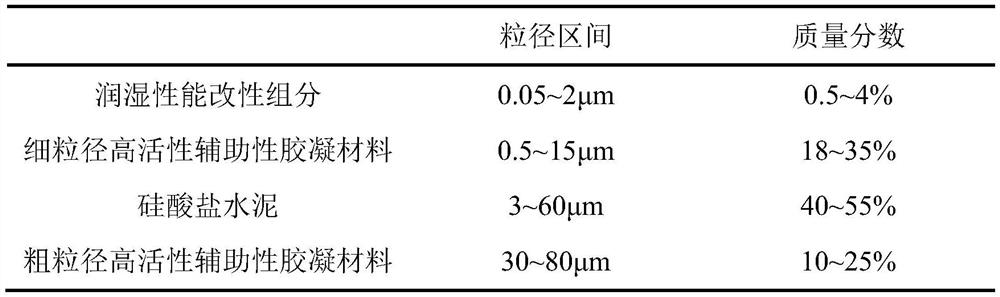

[0045]The low-wetting, high-durability composite Portland cement in this example is mainly composed of slag, Portland cement, low-calcium fly ash and wettability modification components; the volume content of each component, each component Table 3 shows the particle size and the performance test of the low-wetting, high-durability composite Portland cement prepared in this example.

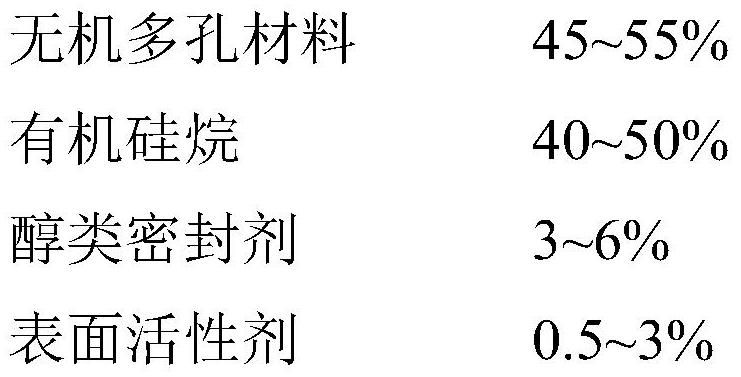

[0046] In this embodiment, the wettability modification component consists of diatomaceous earth (18%), zeolite (36%), dodecyltrimethoxysilane (40%), polypropylene glycol (molecular weight is 800) (4%) , dodecyl glucoside (2%); the technical parameters of microwave-chemical treatment compound modification are: microwave power 150W, irradiation time 4 minutes, sulfuric acid concentration 2mol / L, sulfuric acid temperature 35°C, oscillation time 60 minutes ;The technical parameters of vacuum loaded organosilane are: chamber pressure 0.1kPa, pressure maintenance time 15 minutes, inorganic porous mater...

Embodiment 2

[0050] The low-wetting, high-durability composite Portland cement in this example is mainly composed of calcined clay, Portland cement, low-calcium fly ash and wettability modification components; the volume content of each component, each group The particle size and performance test of the low-wetting, high-durability composite Portland cement prepared in this example are shown in Table 4.

[0051] In this embodiment, the wettability modification component consists of diatomaceous earth (22%), zeolite (30%) butyltriethoxysilane (44%), polyethylene glycol (molecular weight is 1000) (3%) , octadecyl glucoside (1%); microwave-chemical treatment compound modified technical parameters are: sulfuric acid concentration 3mol / L, sulfuric acid temperature 40 ℃, oscillation time 60 minutes, microwave power is 200W, irradiation time is 3 minutes; the technical parameters of vacuum loading organosilane are: chamber pressure 0.1kPa, pressure maintenance time 15 minutes, inorganic porous ma...

Embodiment 3

[0055] In this example, the low-wetting and high-durability composite Portland cement is mainly composed of slag, Portland cement, limestone and wettability modification components; the volume content of each component, the particle size of each component and The performance tests of the low-wetting, high-durability composite Portland cement prepared in this example are shown in Table 5.

[0056] In this embodiment, the wettability modification component consists of diatomite (20%), zeolite (27%), octadecyltrimethoxysilane (47%), polyvinyl alcohol (molecular weight is 800) (5 %), glyceryl laurate (1%); the technical parameters of microwave-chemical treatment compound modification are: sulfuric acid concentration 4mol / L, sulfuric acid temperature 40 ℃, oscillation time 30 minutes, microwave power is 200W, irradiation time is 2 minutes; the technical parameters of vacuum loading organosilane are: chamber pressure 0.1kPa, pressure maintenance time 15 minutes, inorganic porous mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com