A kind of low temperature ultra high performance concrete and its preparation method and application

An ultra-high-performance concrete technology, which is applied in manufacturing tools, building maintenance, ceramic molding machines, etc., can solve problems such as construction difficulties of ultra-high-performance concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also provides the preparation method of the low-temperature ultra-high performance concrete described in the above technical solution, comprising the following steps:

[0033] Mix cementitious material, aggregate, mineral admixture, water reducing agent, defoamer, early strength agent, retarder and antifreeze to obtain concrete matrix;

[0034] After mixing the concrete matrix with water, a slurry is obtained, and steel fibers are added to the slurry to obtain a low-temperature ultra-high performance concrete.

[0035] The present invention mixes cementitious material, aggregate, mineral admixture, water reducing agent, defoaming agent, early strength agent, retarder and antifreezing agent to obtain concrete matrix. In the present invention, the temperature of the mixing is preferably -5 to 10°C, more preferably -5 to 5°C, and more preferably -5 to 0°C. The present invention does not specifically limit the method of mixing the cementitious materia...

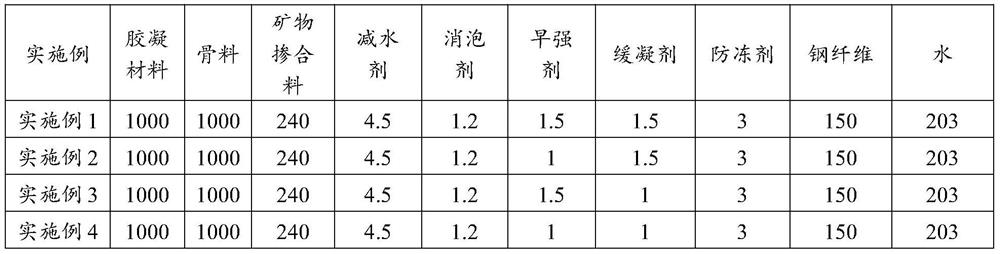

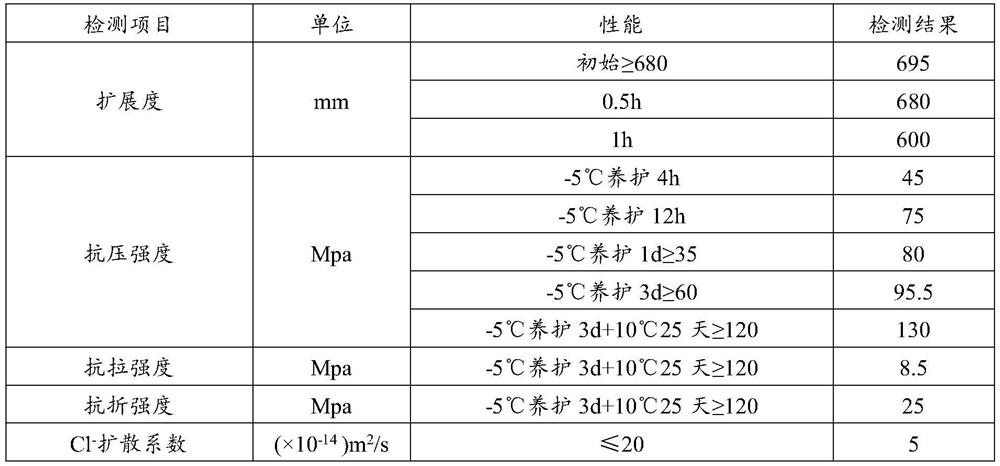

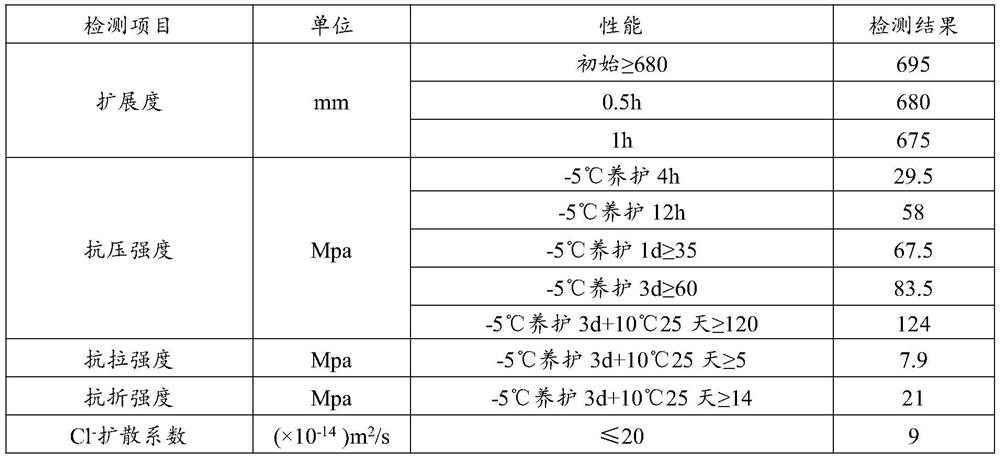

Embodiment 1~4

[0040] Mix the cementitious material, aggregate, mineral admixture, water reducing agent, defoamer, early strength agent, retarder and antifreeze at -5°C using a high shear forced mixer to obtain a concrete matrix; Adding water to the concrete matrix and stirring for 6 minutes to obtain a slurry, adding steel fibers to the slurry, and continuing to stir for 5 minutes to obtain a low-temperature ultra-high performance concrete. Among them, the cementitious material is 52.5 grade ordinary Portland cement, high belite sulfoaluminate cement and high alumina cement mixed with a mass ratio of 7:2:1; the aggregate is quartz sand, and the quartz sand has a medium particle size. The mass ratio of 20-40 mesh coarse quartz sand and 40-70 mesh fine quartz sand is 1:1.5; the mineral admixture is ultra-fine fly ash microbeads with a particle size of 1-5 μm; water reducing agent It is a polycarboxylate water reducing agent (PC-100 developed by Shanghai Yingshan New Material Technology Co., L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com